Proactive Safety Measures for Construction and Warehousing

Safety in construction and warehousing usually breaks down in overlooked moments. A missed update between shifts, a hazard that goes unreported, or a safety message that never reaches the floor can turn routine work into serious risk. When teams are spread across job sites, warehouses, and rotating schedules, reactive safety programs leave too much to chance. Proactive safety measures focus on identifying risks early, reinforcing safe behavior every day, and ensuring critical information reaches workers where the work happens.

TL;DR

- Proactive safety programs reduce incidents by identifying hazards before workers get hurt, especially across distributed construction and warehouse sites

- Falls, struck-by incidents, equipment movement, and ergonomic strain remain the most common risks that require consistent controls and daily reinforcement

- Safety measures work best when they combine engineering controls, clear procedures, and regular site-specific communication

- Two-way safety communication allows workers to report hazards, confirm instructions, and participate actively in prevention efforts

- Training and alerts must reach workers in languages they understand and through channels they actually use on the job

- Yourco helps operations teams reach every frontline worker instantly with SMS-based, multilingual communication that works on any phone

Download our free Construction SOP and Warehouse Safety SOP templates.

Understand the Safety Risks Construction and Warehousing Workers Face

Before implementing safety measures, operations managers need a clear picture of what their teams face daily. Construction workers encounter the "Fatal Four": falls, struck-by incidents, electrocutions, and caught-in/between hazards. Warehouse workers deal with high injury rates from loading dock operations, forklift incidents, and repetitive material handling. Heat-related hazards are also rising sharply across both industries.

Implement Fall Protection at Every Height

Fall protection keeps construction workers alive. Most companies start protection at six feet, but plenty of fatal falls happen below that mark, so don't wait to protect your workers at lower heights.

To implement effective fall protection:

- Install guardrail systems as the primary passive defense that doesn't rely on worker behavior

- Use safety nets as secondary protection when guardrails aren't practical

- Deploy personal fall arrest systems as individual protection when other methods aren't feasible

- Verify anchorage system stability before elevated work begins

- Evaluate equipment needs for specific heights and tasks

- Conduct site-specific hazard assessments for each elevated activity

- Document and communicate safe work procedures to all workers

- Add permanent guardrails on warehouse mezzanines, elevated platforms, and dock levelers with safety barriers

- Ensure adequate lighting in elevated work areas across all shifts

Treating fall protection as a baseline requirement at every height helps prevent routine tasks from turning into life-altering incidents.

Prevent Struck-By Incidents with Work Zone Controls

Struck-by incidents are the second leading cause of construction fatalities, with most involving heavy equipment. Protecting workers from moving vehicles, falling objects, and swinging loads requires both individual vigilance and systematic controls.

To prevent struck-by incidents:

- Establish traffic control plans that separate pedestrians from equipment operations using signage and physical barricades

- Create designated pedestrian walkways clearly marked and separated from vehicle traffic

- Implement spotter systems for backing vehicles in areas with limited visibility

- Ensure qualified personnel operate cranes, signal equipment, and rig loads properly

- Require the use of appropriate PPE in equipment areas, with hard hats for overhead hazards, high-visibility apparel to improve worker visibility, and steel-toed boots to protect against crushing injuries

These controls work together to significantly reduce struck-by risks. Engineering solutions like barriers and walkways come first, while PPE serves as the final line of defense when other controls aren't feasible.

Address Ergonomic Hazards Before Injuries Occur

Musculoskeletal disorders develop from repeated exposure to ergonomic risk factors, but proactive programs can identify and fix these hazards before workers experience symptoms.

To address ergonomic hazards effectively:

- Conduct proactive assessments to identify risks before injuries occur

- Involve workers directly as frontline employees often spot ergonomic problems managers can't see from a distance

- Redesign workstation layouts to minimize reaching, bending, and awkward postures

- Install adjustable-height work surfaces to accommodate workers of different sizes

- Add mechanical assists for repetitive lifting, transport, storage, and packaging tasks

- Encourage early symptom reporting so issues are caught before they become serious injuries

- Train workers on proper lifting techniques and how to recognize early warning signs

When engineering solutions aren't immediately feasible, administrative controls like job rotation, regular breaks, and work pace adjustments fill the gap. Together, these approaches prevent musculoskeletal disorders and create safer conditions across all shifts.

Prepare Emergency Response Plans for Every Site

Emergency action plans transform chaos into coordinated response when seconds count. Every site needs a plan that identifies the types of emergencies reasonably expected (fires, severe weather, medical emergencies, or chemical releases) and specifies protective actions for each scenario. On multi-employer construction sites, employers should work with subcontractors to develop unified procedures and establish clear evacuation routes and communication chains before an actual emergency creates dangerous confusion.

To build an effective emergency response plan:

- Identify site-specific emergencies and develop response procedures for each scenario

- Assign clear roles and responsibilities so every worker knows what to do during an emergency

- Establish evacuation routes and ensure all personnel know where to go

- Create communication chains so supervisors can account for everyone after an evacuation

- Coordinate across subcontractors on multi-employer sites to unify procedures

- Conduct regular drills and update plans based on performance

- Assess emergency medical response times for remote sites to determine on-site medical capabilities needed

These preparations ensure that when emergencies occur, your team responds with coordination rather than confusion and protects workers when it matters most.

Build a Two-Way Safety Communication Culture

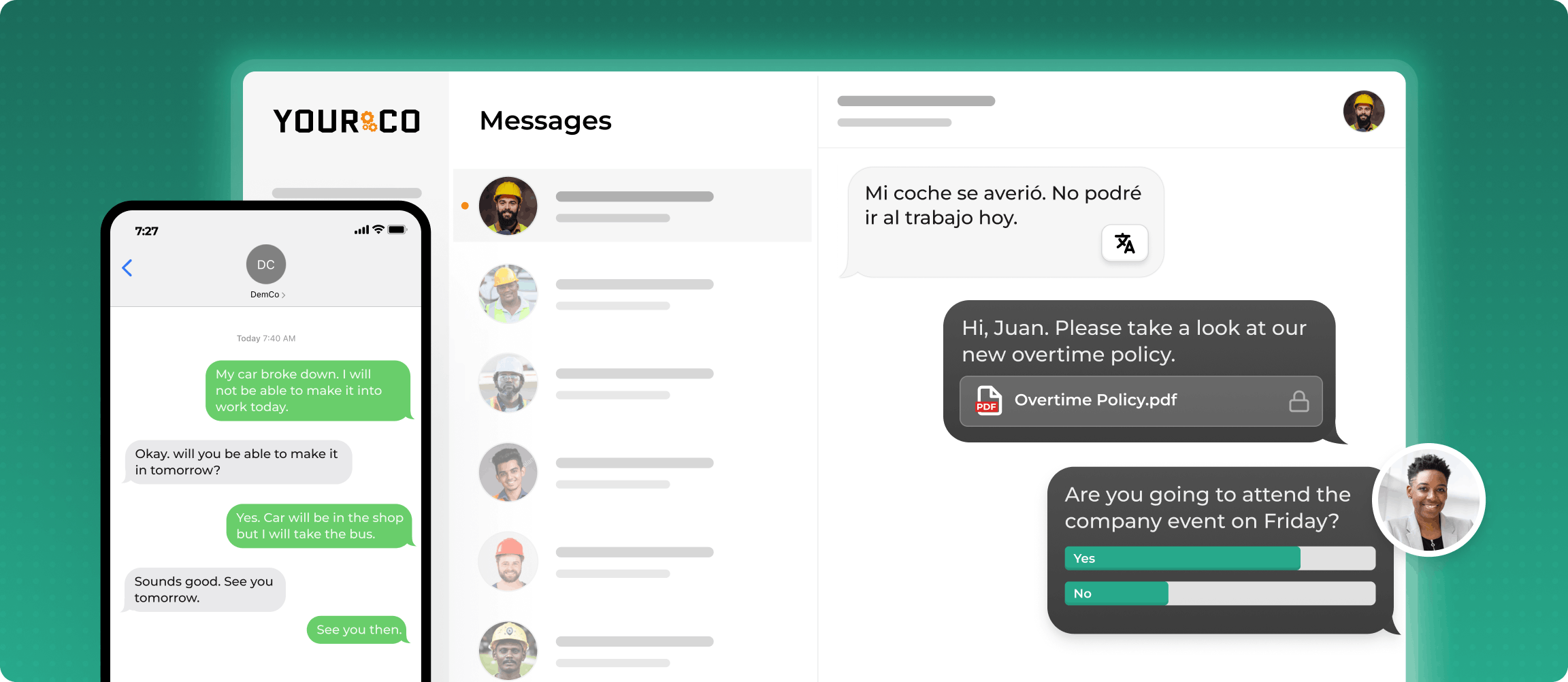

Safety announcements only work when workers actually receive and understand them. For frontline workers spread across job sites and shifts who don't check email or use company apps, communication must meet them where they are. SMS-based systems reach workers on any mobile phone without internet access, app downloads, or technical training.

Two-way communication creates feedback loops where workers can report hazards and receive guidance, which enables proactive hazard identification before incidents occur.

To build effective safety communication:

- Establish channels for hazard and near-miss reporting so workers can flag issues from the field

- Verify safety messages actually reach all workers rather than assume delivery

- Enable two-way conversations between frontline workers and supervisors

- Use polls and surveys to check understanding and gather feedback

These practices create safety cultures where every worker participates actively in hazard identification and prevention, which consistently drives lower injury rates across organizations.

Train Workers in Languages They Understand

Effective safety training means workers actually understand the content. Traditional training approaches fall short for frontline workers who don't sit at desks. For operations managers with diverse, multilingual crews, training materials and safety communications must reach workers in their preferred languages with comprehension verification beyond just attendance.

To train workers effectively:

- Provide training materials in workers' preferred languages so content is actually understood

- Verify comprehension rather than just attendance to confirm workers grasp critical information

- Deliver toolbox talks through mobile-friendly channels workers already use, like SMS

- Use visual training materials available in multiple formats for different learning needs

- Document training completion and understanding for compliance purposes

Structured daily toolbox talks customized to specific tasks and sites consistently outperform informal safety discussions and ensure training reaches every worker effectively.

Reach Every Worker Instantly With Yourco

Protecting construction and warehouse workers requires safety measures that account for how frontline teams actually work: mobile, distributed, multilingual, and often without access to company email or internet. Traditional communication tools leave dangerous gaps when workers can't receive critical safety alerts or report emerging hazards.

Yourco bridges this gap with SMS-based communication that reaches every employee on any mobile phone, including basic flip phones. With high read rates and delivery in seconds, safety alerts actually reach the workers who need them. The platform's AI-powered translation enables communication across 135+ languages and dialects, ensuring every team member receives critical information in a language they understand.

Two-way communication enables workers to report hazards from the field, confirm they've evacuated dangerous areas, and respond to safety check-ins. Yourco's Frontline Intelligence transforms these everyday interactions into real-time insights on safety signals and workforce risks, giving operations managers visibility they've never had before.

Try Yourco for free today or schedule a demo and see the difference the right workplace communication solution can make in your company.

Frequently Asked Questions

What are the most common causes of injuries in construction and warehousing?

In construction, falls account for the largest share of fatalities, followed by struck-by incidents, electrocutions, and caught-in/between hazards. Warehousing operations present distinct injury patterns, with loading dock operations and forklift incidents among the most common hazards, along with ergonomic issues from repetitive lifting and material handling tasks.

How often should safety training be conducted for frontline workers?

Many employers provide safety training initially when workers are hired, when new equipment or processes are introduced, and at minimum annually. Daily or weekly structured toolbox talks help reinforce safety awareness between formal training sessions.

Why is multilingual safety communication important?

Workers need to understand safety information to act on it effectively. Providing training and safety communications in languages employees understand helps ensure comprehension of critical procedures and emergency instructions across diverse workforces.

What makes SMS effective for safety communication with frontline workers?

SMS reaches workers on any mobile phone without requiring app downloads, email addresses, or internet connectivity. Messages arrive instantly and achieve high read rates, making SMS particularly effective for time-sensitive safety alerts.

How can operations managers verify that safety messages reach all workers?

Two-way communication platforms enable managers to verify that safety messages reached intended recipients. Polls and surveys verify comprehension of safety protocols, while read receipts provide documentation that communications reached their intended audience.

What are the three safety rules for a warehouse?

While every warehouse has its own layout and risks, many operations rely on three foundational safety rules to reduce injuries and keep work running smoothly:

- Keep people and equipment separated: Clearly marked walkways, barriers, and traffic rules help prevent collisions between workers, forklifts, and other moving equipment. Most serious warehouse injuries involve vehicle movement, so physical separation does a lot of the heavy lifting.

- Lift and move materials safely: Workers should use proper lifting techniques, mechanical aids when available, and avoid rushing manual handling tasks. Repetitive lifting and awkward movements are a major source of injuries, so slowing down and using the right tools matters.

- Report hazards immediately: Spills, damaged pallets, blocked exits, or malfunctioning equipment should be reported as soon as they’re noticed. Quick reporting allows supervisors to fix small issues before they turn into serious incidents.

Together, these rules focus on prevention rather than reaction. They work best when reinforced through regular training and clear, reliable communication so everyone understands expectations and knows how to speak up when something isn’t right.