How to Build Mandatory Evacuation Policies That Save Lives

Natural and workplace disasters like hurricanes, earthquakes, electrical fires, and chemical leaks can turn an ordinary shift into chaos with no warning. When every second counts, your team can't afford guesswork. You need a clear, written plan that tells people exactly when to move, where to go, and who is in charge. A mandatory evacuation policy delivers a roadmap that saves lives, reduces panic, and shows employees you've planned for their safety.

The steps ahead will help you build or refine that policy, from setting unmistakable triggers to choosing backup assembly points.

Why Your Multi-Site Operation Needs Mandatory Evacuation Policies

Without a written evacuation plan, every minute of an emergency turns into hesitation, and hesitation costs lives. Clear policies give your team an automatic playbook so people act fast rather than freeze.

OSHA requires companies with 10 or more employees to have written evacuation procedures under standard 29 CFR 1910.38. This includes documenting evacuation routes and methods to account for all employees after evacuation. When you outline responsibilities ahead of time, you avoid regulatory fines and shorten response time because no one is left guessing.

Rehearsed, policy-driven evacuations reduce casualties by establishing a clear chain of command. When you detail specific triggers, like a local government order, rising water levels, or a gas sensor alarm, everyone knows exactly who gives the evacuation order and when that order becomes mandatory.

Non-desk workers need special attention since they never check corporate email. Warehouse staff, maintenance crews, and retail teams depend on alarms, announcements, and text alerts to stay informed. When your evacuation policy accounts for everyone, regardless of their device or location, you turn a vulnerable moment into a coordinated exit.

1. Define Clear Evacuation Triggers

When every person on your crew knows the exact moment to leave, they move faster, hesitate less, and stay safer. Clear triggers eliminate the guesswork that slows down emergency response.

Objective criteria for each hazard you face should be your foundation: fire alarms that won't silence, National Weather Service tornado warnings, or gas sensors hitting preset thresholds. While establishing these measurable benchmarks, identify who has evacuation authority and ensure at least one backup covers every shift.

Manufacturing environments face unique trigger challenges. Chemical processing plants might set automatic evacuation at specific parts-per-million readings, while construction sites may trigger based on wind speeds that make crane operation unsafe. Use measurable thresholds like "water over the loading-dock ramp" or "equipment temperature above 180°F" to keep judgment calls to a minimum.

Recommended evacuations allow employee choice, but mandatory orders carry legal weight that can affect wages and insurance coverage. Each trigger needs plain-language instructions tied directly to action: "If sensor A reads over 50 ppm, evacuate north gate immediately." For severe weather: "On a tornado warning, move to interior hallways. Do not attempt to leave the property."

Regular review after drills and near-misses keeps these triggers sharp and relevant. Clear triggers, clear authority, and routine updates set the stage for an orderly evacuation when every second counts.

2. Establish Safe Evacuation Routes and Assembly Points

Your team will only move quickly if every exit, path, and gathering spot is crystal-clear, reinforced often, and backed by more than one way out.

Map at least two evacuation routes from every work area. Manufacturing floors with heavy machinery need especially wide paths, as a forklift breakdown or overturned pallet can block primary exits in seconds. Relying on a single corridor creates bottlenecks the moment smoke, debris, or crowds block the door. Walk each path yourself, time how long it takes, and clear tripping hazards now, because during a crisis there's no time to push aside equipment or extension cords.

Mark routes so no one needs to stop and think. Use photoluminescent arrows and exit signs that stay visible during blackouts. Add simple wording in the main languages your team speaks, especially if you’re in an industry with a diverse workforce like construction and logistics.

Assembly points deserve equal attention and careful consideration for your specific work environment. Warehousing operations need spots that accommodate large numbers while staying clear of truck traffic. Pick locations that keep people far enough from danger but close enough for headcounts, shelter, and medical help. Key criteria include:

- 150 ft or more from the building

- Clear of glass, vehicles, and overhead power lines

- Accessible to emergency vehicles

- Covered or shaded when possible

- Away from loading docks and equipment yards

Update every route after renovations, layout changes, or close calls. Post fresh maps, brief every shift, and practice until the route becomes second nature.

3. Assign Roles and Responsibilities

When everyone knows their job, you evacuate faster and account for every person without second-guessing.

Begin with clear authority. Name the individual who issues evacuation orders and designate reliable backup coverage for nights and weekends. This prevents dangerous delays when primary decision-makers are off-site. Cover every shift so authority never lapses, especially important for 24-hour operations like manufacturing plants and logistics centers.

Build a network of helpers with about one evacuation warden for every 20 employees. Wardens sweep their assigned area, direct traffic to exits, and report headcounts at the assembly point. Choose people who stay calm under pressure and work in different departments. This ensures coverage even when some team members are absent.

Assign specific emergency duties to reliable team members based on your facility type. Manufacturing operations need designated operators who can power off machinery or secure hazardous materials. Construction sites require crews who can shut down heavy equipment safely. Create two-person teams to help anyone with mobility, hearing, or vision challenges, and have these teams escort visitors who may not know the layout.

Multilingual teams benefit from strategic pairing. Match wardens with bilingual colleagues or keep printed cue cards in the top three languages spoken onsite. Simple phrases such as "Follow me," "Use stairs," "South lot" reduce confusion and speed up the process, particularly vital for diverse workforces in logistics and construction.

Document every role and post an updated roster near time clocks and break rooms. Train supervisors to model composure through tabletop exercises where they practice giving orders using plain language.

4. Communicate in Real Time During Emergencies

Your evacuation plan only works if every employee gets clear instructions the moment danger appears.

Construction sites and logistics operations face unique communication challenges with workers spread across multiple buildings, outdoor crews without Wi-Fi access, and contractors using different languages.

Text alerts are the fastest way to reach people who are not sitting at a desk. With a 98% read rate and no need for Wi-Fi, SMS cuts through the noise and lands on any basic phone, including flip phones common among experienced tradespeople. Most workers see the message within minutes, even in areas where radio communication fails.

Don't rely on a single channel. Pair texts with loud alarms, PA announcements, and flashing lights for noisy work areas like manufacturing floors or construction zones. Having multiple ways to communicate keeps the message moving even when one method fails.

Real-time translation can push the same alert in more than 135 languages, so contractors and seasonal staff don't waste seconds figuring out confusing instructions. Keep every instruction short and direct: "Evacuate through south exit. Meet at lot B." Skip idioms and technical terms that might confuse non-native speakers.

Connect your notification system to local emergency services and building controls. Mass notification tools can pull fire-panel data, trigger door releases, and send status reports back to managers. SMS keeps working during power failures because it uses the carrier's backup power.

5. Create Message Templates for Consistency

Pre-written templates shave minutes off your response time and keep every employee reading the same, clear instructions instead of improvised texts.

Build each template around one clear goal using direct language. A simple structure works best: hazard, action, location, and timing:

EVACUATE NOW. Hazard: {{hazard_type}}. Use {{route}} exit. Meet at {{assembly_point}}.

Templates work especially well for multi-shift operations like warehousing and manufacturing, where different supervisors need to send identical instructions. Night shift managers can access the same pre-approved messages as day teams, ensuring consistency across all hours of operation.

Keep a small set of templates covering common scenarios:

- Mandatory evacuation orders with severity indicators

- Route changes or alternate exits

- All-clear notifications

- Follow-up headcount checks

Stick to 160 characters so the full alert arrives in a single text message. Use action verbs like "Evacuate," "Proceed," and "Reply" so no one wonders what to do next.

Store templates inside your notification platform where any authorized manager can access them. Review and refresh the wording after every drill for consistency and higher compliance rates.

6. Conduct Regular Drills and Training

Practice is the only way to know your evacuation plan will hold up when it matters.

Schedule quarterly exercises that rotate through different scenarios: fire in the loading dock this quarter, chemical spill next time, severe weather after that. This rotation ensures all teams practice various emergency types rather than becoming experts in just one scenario. Mix announced and unannounced drills. Announced versions let new employees learn the basics, while surprise versions test real-time reactions.

During drills, track timing and accountability carefully with special attention to your facility's unique challenges. Manufacturing plants should time how long equipment shutdown takes. Construction sites need to practice securing tools and materials. Start a stopwatch when the alarm sounds, record how long it takes for the last person to clear the building, and note any blocked exits or communication problems. At the assembly point, run a headcount and document anyone missing.

Collect feedback immediately through quick text surveys: ask what felt confusing, which routes were crowded, and what instructions were hard to hear. Document every comment alongside timing information and revise procedures as soon as drills reveal gaps.

Keep thorough records of date, scenario, participants, timing, and lessons learned. Share a brief recap with all employees so everyone sees improvements and stays engaged.

7. Document and Review Policies Regularly

A written, up-to-date record of your evacuation procedures keeps everyone accountable and shows regulators that you take safety seriously.

While we're not legal professionals, many employers look to OSHA's 29 CFR 1910.38, which calls for a written Emergency Action Plan (for 10 or more employees) available for employees to review. Create both digital and hard-copy versions. This redundancy will prove useful you if power or network connections fail.

Schedule formal reviews at least once a year, sooner if you add new production lines, remodel exits, or shift to 24-hour operations. Manufacturing facilities should review after major equipment installations. Construction companies need updates when moving to new job sites.

Keep a running log of every emergency message you send, tracking alarms, SMS alerts, and PA announcements with timestamps and recipient lists.

Training deserves equally tight documentation. Log who attended drills, which roles they practiced, and any performance gaps you observed. Make sure frontline supervisors can grab the plan at a moment's notice through laminated quick-reference cards or bookmarked links on company tablets.

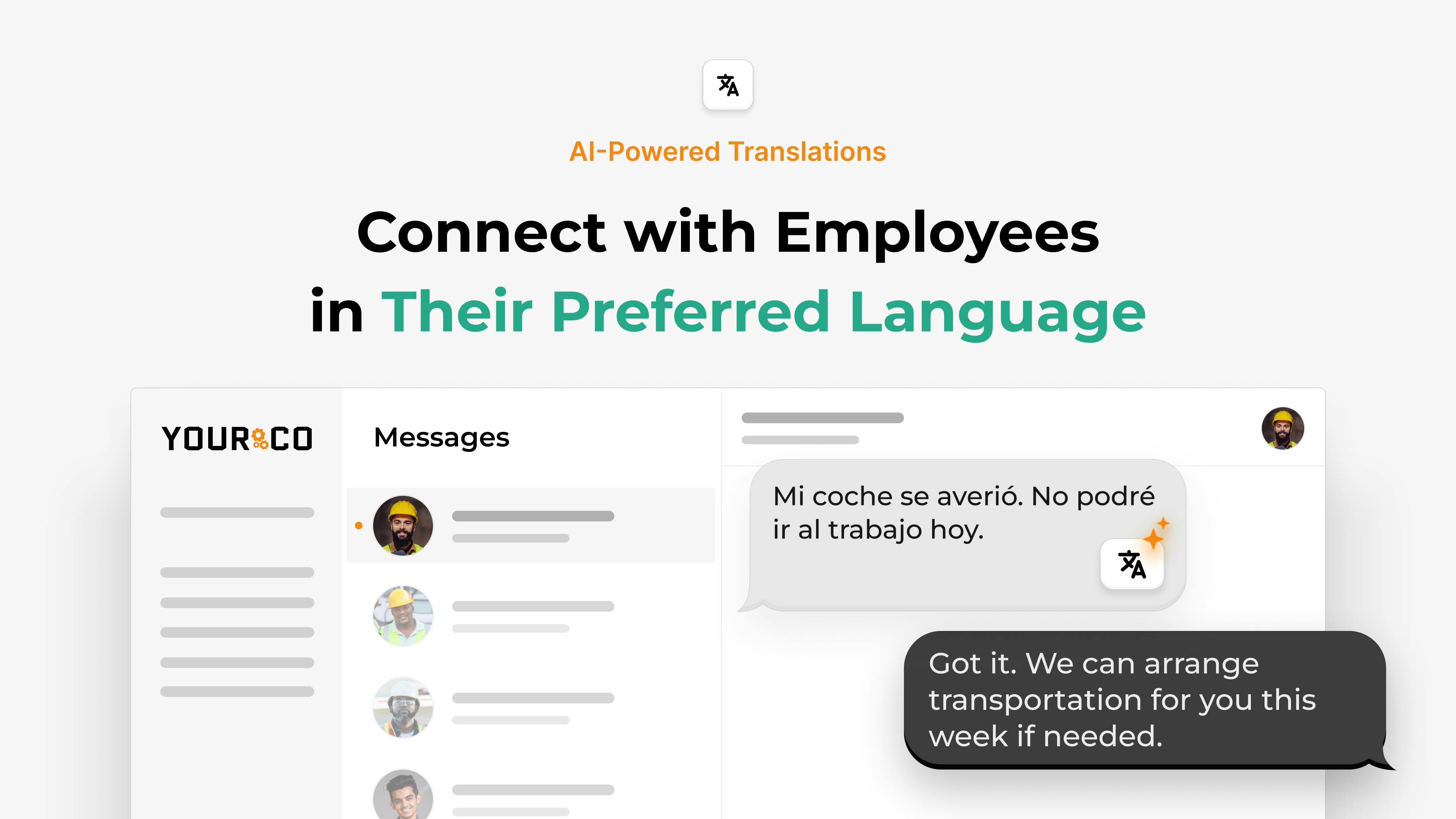

Send Life-Saving Alerts Instantly with Yourco

When seconds matter, Yourco gets the right message to every employee, fast. SMS alerts reach basic phones without downloads or data. Messages are auto-translated into 135+ languages and dialects, so no one is left guessing. You write one alert and every person receives it in their preferred language.

Your evacuation policy becomes easy to execute with pre-loaded templates. Use simple variables like {{hazard_type}}, {{route}}, and {{assembly_point}}. Authorized managers can send the correct message in a few clicks, on any shift, at any site. Use one-way broadcasts for the initial order, then switch to quick two-way check-ins for headcounts. Managers see replies roll in and can follow up with anyone missing.

Multi-location and group targeting keep messages relevant. You can alert only the affected building, route a second notice to supervisors, and share an all-clear to the entire region. Every alert is logged with timestamps and recipients, helping you review drills, improve response times, and prepare for audits.

Try Yourco for free today or schedule a demo and see the difference the right workplace communication solution can make in your company.

FAQs

What's the difference between a fire drill and a mandatory evacuation?

A fire drill is practice. A mandatory evacuation is the real thing. During drills, everyone follows planned routes while no danger exists. Mandatory evacuations happen when real threats put people at risk. Once the evacuation order is mandatory, staying for "just one more task" isn't an option.

How often should evacuation policies be reviewed?

Review your full policy at least once a year, then make quick updates whenever something changes—new equipment, building changes, leadership turnover, or lessons from recent drills. Schedule your annual review now so it doesn't get forgotten, and revisit the policy right after any incident or near-miss.

What's the best way to reach non-English-speaking employees during emergencies?

Send translated SMS alerts that reach everyone, including workers without smartphones or email access. Translation tools can convert short commands into more than 135 languages in seconds. Keep messages simple (e.g., "Evacuate to south lot now") and add visual cues like flashing strobes for noisy areas.

Can evacuation communications be used as legal documentation?

Yes, when messages are logged automatically, they create time-stamped records showing who was notified, when, and how. Mass notification platforms keep delivery receipts and response data in secure audit trails. While we're not legal professionals, many safety managers store these records alongside OSHA documentation requirements.