What Is Shop Floor Management? Definition and Strategies

Manufacturing floors across industries face a persistent challenge: maintaining consistent quality, safety, and efficiency while meeting accelerating production demands. The solution? Shop floor management (SFM) – a leadership approach that bridges the gap between "top floor" offices and production areas by placing decision-making directly where work happens.

Shop floor management serves as the backbone of lean manufacturing excellence. It transforms how production teams operate, communicate, and improve their processes. And the impact of SFM proves substantial, Manufacturing plants that implement these shop floor management strategies have reduced changeover times by 18% within just six months.

This guide covers essential components for operational success: daily routines, the three pillars of Gemba, Genchi Genbutsu, and Genjitsu, plus a practical implementation roadmap connecting traditional lean manufacturing principles with modern digital tools.

Organizations with effective shop floor management consistently report improvements in:

- Production efficiency and throughput

- Product quality and consistency

- Waste reduction and resource utilization

- Safety incident prevention

- Employee satisfaction and retention

Whether you manage operations focused on productivity and profits, optimize processes as a continuous improvement professional, or seek to boost employee engagement as an HR leader, you'll find practical takeaways from both Toyota's time-tested lean approaches and modern digital methods. These shop floor management strategies boost real-time communication and help teams thrive in today's fast-paced manufacturing environment.

Why Shop Floor Management Matters

Shop floor management focuses on the base-level operations and leadership tasks in production to achieve continuous process improvement. This systematic approach transforms how manufacturers control their production processes, enhancing efficiency, quality, and competitiveness at the point where teams create value.

Toyota pioneered lean manufacturing in the 1980s, and shop floor management has evolved significantly since then. Simple visual boards and daily talks have grown into smart digital systems that blend traditional lean methods with real-time data analytics, IoT sensors, and mobile platforms. Today's approach integrates layout planning, workflow optimization, and visual management to create responsive, efficient production environments.

The benefits of shop floor management cross industry lines and help build safer, more efficient operations while strengthening workforce engagement. Here's what this means for you:

- Operations managers see direct bottom-line results through reduced downtime, improved throughput, and lower costs.

- Continuous improvement professionals gain a systematic problem-solving framework with data to back decisions.

- HR leaders observe workforce engagement climb as employees become active participants in improvement rather than passive operators.

These improvements directly enhance customer On-Time-In-Full (OTIF) performance, strengthening your competitive position in an increasingly demanding marketplace. What’s more, modern practices encourage collaboration between leadership levels, reduce waste and errors, while also enhancing productivity and safety.

The Three Pillars of Lean Shop Floor Management

Effective shop floor management rests on three foundational principles that transform traditional manufacturing into a lean, responsive operation. The Three Pillars of the Shop Floor Management Approach, Gemba, Genchi Genbutsu, and Genjitsu, provide the philosophical framework that turns theory into daily practice.

Gemba: Leadership on Site in Shop Floor Management

The foundation begins with Gemba, a Japanese concept meaning "real place," where value is created. This principle emphasizes that effective leadership must be physically present on the production floor, engaging directly with processes and people rather than managing from distant offices.

Leaders practicing Gemba understand you can't manage what you can't see. By spending time where the actual work happens, managers gain firsthand insight into challenges, bottlenecks, and opportunities that never surface in conference room discussions. This builds trust with frontline workers and shows genuine commitment to excellence.

Genchi Genbutsu: Leadership By Example

Genchi Genbutsu goes beyond observation to active leader participation in problem-solving. Rather than delegating issues up the chain, this approach encourages managers to roll up their sleeves and solve one problem with operators daily. This hands-on method builds trust, demonstrates commitment, and gives employees ownership of improvements. When workers see leaders getting their hands dirty, it breaks down hierarchical barriers and creates a collaborative problem-solving culture.

Genjitsu: Decision-making Based on Data

Genjitsu anchors decision-making in real data rather than assumptions or gut feelings. This principle demands discipline in collecting, displaying, and acting on actual facts. A simple but powerful practice: post the previous shift's OEE before 9 a.m. This creates immediate visibility into performance trends and forces teams to confront reality with concrete numbers.

These three principles work together to create transparency, accountability, and continuous improvement on the shop floor. They form the philosophical foundation for the practical tools and methods that make shop floor management truly effective.

Core Components & Tools You Need for Shop Floor Management

Building effective shop floor management requires seven interconnected components that work together to create a culture of continuous improvement and operational excellence. Each element supports the others, forming a comprehensive system that transforms your manufacturing floor into a responsive, efficient operation.

Lean Leadership Culture

Successful shop floor management requires leaders who actively engage with frontline operations rather than managing from their offices. Leaders must spend time on the floor, ask questions, and demonstrate commitment to improvement through actions rather than directives. Essential elements include leader standard work protocols that define specific leadership activities, scheduled Gemba walks where managers observe processes firsthand, and coaching frameworks that help supervisors develop problem-solving skills in their teams.

Process Confirmation and Operational Control

Ensuring operators follow standard work procedures consistently reduces variability and maintains quality across all shifts. This approach focuses on verification rather than assumption, with teams using systematic checks to confirm processes meet specifications. Key elements include standardized checklists for critical operations, regular process audits that compare actual work to documented procedures, and control points that prevent defective products from moving to the next stage.

On-Site Communication and Meetings

A structured information flow keeps everyone aligned and responsive to changing conditions. Teams establish regular touchpoints where they share status, discuss problems, and coordinate responses instead of relying on informal communication or lengthy email chains. The foundation includes daily stand-ups that follow standard agendas covering safety, quality, delivery, and people issues. Implementing effective warehouse safety strategies ensures a safer work environment. Shift handover protocols ensure critical information transfers between teams; and escalation procedures quickly bring the right people together when problems arise.

SFM Board and Visual Management Board

With instant visibility into performance, issues, and improvement activities, the invisible becomes visible for everyone on the floor. Teams use these boards as central communication hubs where they can quickly assess status and identify what needs attention. Essential visual elements include Andon lights that signal when assistance is needed, Kanban cards that control workflow and inventory levels, and digital dashboards that display real-time metrics like OEE, quality rates, and safety performance.

Sustainable Problem-Solving

establishes systematic approaches to addressing root causes rather than just symptoms, ensuring problems stay solved and don't resurface. Teams apply structured methodologies that help them dig deeper into issues and implement lasting solutions. Core techniques include the 5 Whys method for root cause analysis, A3 reports that document problems and solutions on a single page, and improvement tracking systems that monitor the effectiveness of countermeasures over time.

Performance Management

creates accountability through measurement, ensuring that improvement efforts translate into tangible results that support business objectives. Managers go beyond simply collecting data to actively using metrics for decision-making and course correction. Key elements include scorecards that track leading and lagging indicators, trend charts that reveal patterns and predict future performance, and performance review cycles that connect individual actions to overall results.

Continuous Improvement (Kaizen)

embeds the philosophy of ongoing enhancement into daily work, making improvement a habit rather than a special event. Everyone contributes to making processes better, safer, and more efficient under this philosophy. Essential methods include suggestion systems that capture and act on employee ideas, Kaizen events that focus improvement efforts on specific problems, and improvement tracking boards that celebrate successes and maintain momentum.

Visual management tools like Kanban boards, flowcharts, PERT charts, Gantt charts, and Andon systems serve as the nervous system of modern shop floor management operations, creating transparent communication across all organizational levels. Teams translate complex information into simple, actionable formats that anyone can understand at a glance, supporting faster decision-making and stronger team coordination.

A 5-Step Roadmap to Implement Shop Floor Management

Implementing shop floor management requires a structured approach that balances quick wins with long-term cultural change. By optimizing manufacturing workflows, you can transform your operations step by step.

Structured Communication and Meetings

Your goal is establishing consistent information flow across all levels of your organization. The biggest pitfall occurs when meetings become one-way broadcasts rather than collaborative problem-solving sessions. Instead of lengthy presentations, implement 10-minute daily stand-ups with a standard agenda covering safety, quality, delivery, and people issues. These structured communications create cross-functional collaboration opportunities where operators share insights directly with supervisors and engineers.

While employee communication apps like Slack or Microsoft Teams can work for desk workers to receive safety alerts, production issues, and wins, the shop floor doesn’t typically have desks. You might want to look into alternate methods like sending employee alerts via SMS text messages.

Leadership Emphasis

Develop leaders who coach rather than command. The major pitfall happens when leaders stay in their offices and avoid practicing Gemba—the fundamental principle of going to see the actual work. Schedule regular Gemba walks where leaders ask open questions and listen more than they speak. This leader standard work approach transforms supervisors into problem-solving partners rather than distant authority figures.

Digitalization

Use technology to enhance visibility and decision-making capabilities. Avoid implementing complex systems that frontline workers find difficult to use—this creates frustration rather than efficiency gains. Start with simple digital dashboards displaying key metrics that update in real-time, making critical information accessible to everyone.

Visualization and Problem-Solving Tools

Make status, issues, and improvements immediately visible to all team members. Don't fall into the trap of creating visuals that look impressive but don't drive action. Implement a simple red/green/yellow system for daily performance tracking that connects directly to problem-solving efforts.

Iterative Process Enhancement

Establish cycles of continuous improvement without overwhelming your team. Attempting too many improvements simultaneously dilutes focus and reduces effectiveness. Focus on one problem area per month with clear before/after metrics to measure genuine progress.

You're ready if your team can answer yesterday's OEE, identify the top issue, name the owner, and provide the due date.

Key Shop Floor KPIs & Metrics for Shop Floor Management

Measuring what matters drives better decisions. The Genjitsu pillar of shop floor management emphasizes data-driven decision-making, and the right KPIs transform raw production data into actionable insights that improve daily operations.

Overall Equipment Effectiveness (OEE) multiplies Availability, Performance, and Quality to create manufacturing's gold standard metric. OEE provides a comprehensive view of how effectively your equipment performs, revealing whether downtime, speed losses, or quality issues are your biggest challenges. Display OEE as a large percentage on your shop floor management board with color coding—green for above 85%, yellow for 70-85%, and red below 70%.

First-Pass Yield captures the percentage of units meeting quality standards without rework. This metric directly impacts both costs and customer satisfaction, as higher first-pass rates mean less waste and faster delivery times. Quality metrics like first-pass yield help teams focus on getting things right the first time rather than fixing problems later.

Scrap Rate reveals the percentage of materials wasted during production. Every point of scrap reduction flows directly to your bottom line while supporting sustainability goals. Monitoring scrap rates helps identify process variations before they become costly problems. Show this as a trending line chart to catch increases early.

Downtime Minutes captures when equipment isn't available for production. This metric helps prioritize maintenance activities and reveals patterns that predict future failures. Use a simple counter that resets daily, with alerts when thresholds are exceeded.

Lead Time spans total time from order to delivery, directly impacting customer satisfaction and cash flow.

Safety Incidents counts recordable injuries and near-misses, serving as a leading indicator of operational excellence.

Employee Suggestions Implemented tallies improvement ideas from workers put into action, measuring both engagement and continuous improvement culture.

Employee Engagement and Turnover can be measured through survey feedback and compared against productivity and safety metrics.

Create a cascading metrics system where workstation data rolls up to department totals and then to plant-wide performance. Review metrics daily for operational adjustments, weekly for trend analysis, and monthly for strategic planning.

Leveraging Technology for Real-Time Communication & Visibility in Shop Floor Management

Digitalization represents Step 3 in your shop floor management implementation roadmap, and for good reason. Technology transforms traditional operations by enabling instant communication and decision-making capabilities that paper-based systems simply cannot match.

Specialized software digitalizes visual boards, automates data collection, and provides remote visibility into operations. These dedicated internal communication tools replace outdated bulletin boards with digital dashboards that update continuously, giving managers instant access to production metrics and equipment status from anywhere in the facility.

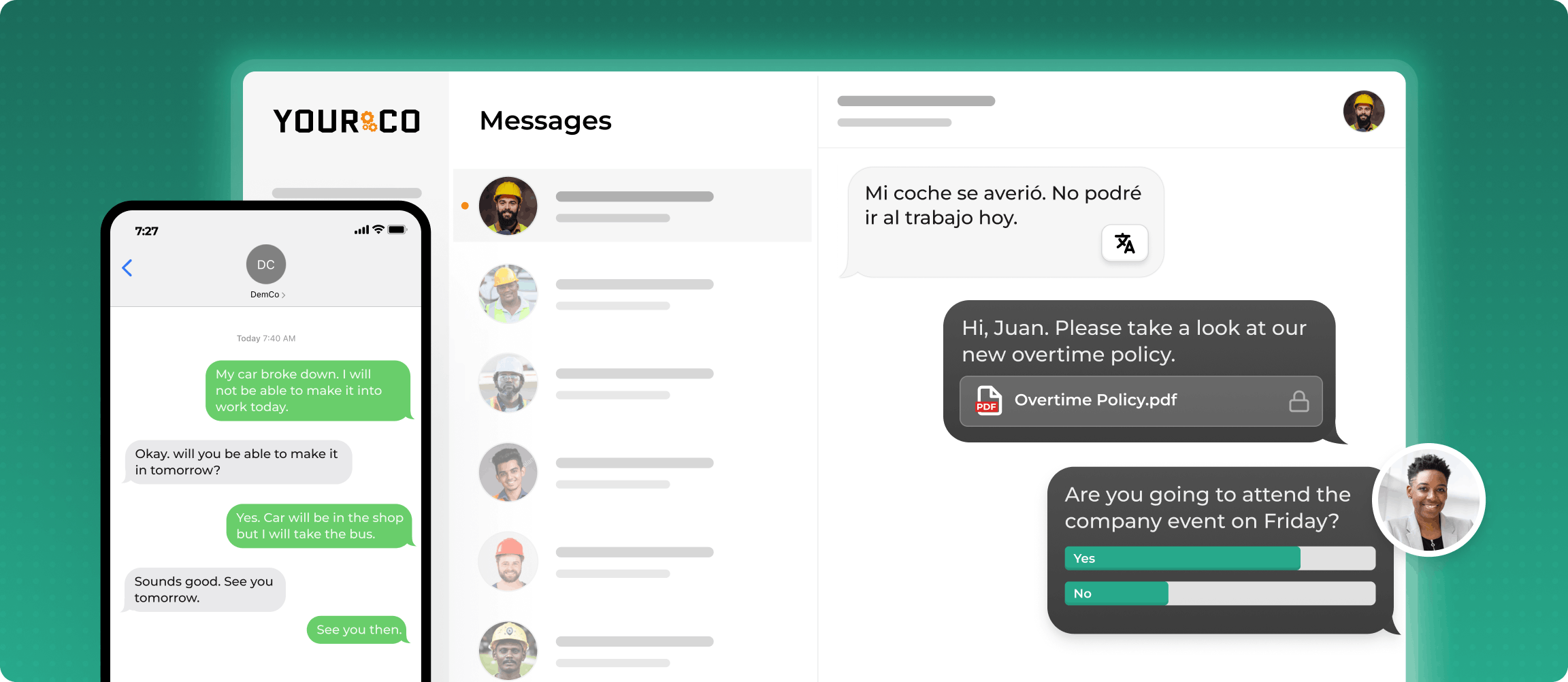

SMS-based communication tools solve a critical challenge that many operations face: reaching non-desk employees effectively. Unlike email that often goes unread, text messaging works perfectly for frontline workers who don't sit at computers all day. Yourco sends instant alerts about equipment issues, shift changes, safety incidents, and production updates directly to employees' phones. By implementing an SMS text messaging setup, you ensure critical information reaches everyone. Since text messages work on any basic phone, you eliminate the communication barriers that often plague shop floor management operations.

The two-way communication capability makes SMS particularly powerful. Workers can quickly report problems or confirm receipt of instructions, creating a continuous feedback loop that keeps operations running smoothly. This instant connection transforms how teams respond to challenges and maintains accountability across shifts.

Shop Floor Management FAQs

What exactly is shop floor management?

Shop floor management is an operational approach that focuses on base-level operations and leadership tasks in production to achieve continuous process improvement. It combines lean principles, visual management, and real-time communication to optimize efficiency, quality, and safety on the manufacturing floor. Think of it as bringing structure and visibility to the place where the actual work happens.

How long does it take to implement shop floor management?

Basic elements like visual boards and daily huddles can start working within weeks, giving you quick wins to build momentum. However, full cultural adoption typically takes 6-12 months as teams develop new habits, refine processes, and embrace continuous improvement across all organizational levels. The key is starting small with consistent application rather than trying to change everything overnight.

What's the difference between shop floor management and production control?

Production control focuses on scheduling, workflow coordination, and meeting output targets. Shop floor management goes deeper by emphasizing leadership development, problem-solving, employee engagement, and systematic improvement of processes. While production control asks "What are we making today?", shop floor management asks "How can we make it better tomorrow?"

What minimum tools do I need to start shop floor management?

Start with visual management boards, standardized daily communications, and basic performance tracking sheets. Add simple problem-solving tools like 5 Whys and checklists. These foundational elements cost little but create immediate visibility and engagement improvements. You don't need fancy software to begin seeing results—just consistent application of these basic tools.

What role does digitalization play in modern shop floor management?

Digital tools enhance traditional practices by providing real-time data visibility, instant communication with non-desk employees, and automated performance tracking. They eliminate paper-based delays and enable faster decision-making while maintaining the human-centered approach. The best digital solutions complement rather than replace face-to-face interaction, making information more accessible without losing the personal connection.

How can I start small with shop floor management?

Begin with 10-minute daily team huddles and one simple visual board showing yesterday's performance. Choose one key metric to track consistently. These small changes build habits and demonstrate value before expanding to more comprehensive systems. Starting small lets you refine your approach through practice rather than getting overwhelmed by a complete system overhaul.

What role does HR play in shop floor management?

HR supports through skills training, recognition programs, and fostering continuous improvement culture. They help develop employee engagement initiatives, create feedback systems, and ensure that frontline worker suggestions are heard and acted upon by management. Effective HR partnerships turn shop floor management from a mechanical process into a people-centered system that builds skills and motivation.

How do I measure the success of shop floor management?

Track quantitative metrics like OEE, defect rates, and response times to issues. Monitor qualitative indicators such as employee suggestion rates, participation in problem-solving, and communication effectiveness. Success shows in both improved numbers and increased workforce engagement. The most powerful indicator is when frontline workers start driving improvements themselves rather than waiting for management direction.

Transform Your Shop Floor Into a Powerhouse of Productivity

SFM represents the difference between struggling and thriving in today's competitive environment. Daily routines, visual management, and real-time communication transform ordinary production floors into lean manufacturing powerhouses. Small actions like 10-minute daily Gemba walks or posting yesterday's OEE metrics before 9 a.m. create ripple effects across your entire operation, building momentum for bigger improvements.

The best part? You don't need massive investments to see results. Start with simple visual boards, standardize your daily communications, and build from there. Modern digital tools make this even easier by connecting everyone in your operation instantly.

This is where Yourco makes a real difference. Traditional approaches often leave your non-desk workforce in the dark between daily communications. Yourco's SMS-based platform reaches every employee directly on their existing phone, without requiring special devices or training. Your team can send shift updates, safety alerts, and performance notifications instantly to keep your entire workforce aligned and informed. You can coordinate equipment maintenance, share production targets, and gather feedback while Yourco ensures everyone receives critical information.

Ready to connect every corner of your operation with clear, instant communication? Try Yourco for free today or schedule a demo and see the difference the right workplace communication solution can make in your company.