Industrial Manufacturing Trends Shaping 2025 and Beyond

The manufacturing industry is moving into a new era where technology, data, and people work together in ways we have never seen before. What used to be experimental is now part of daily operations. Artificial intelligence is running production lines, digital twins are guiding decisions in real time, and collaborative robots are working side by side with human teams.

At the same time, connected worker platforms, private networks, and smarter supply chains are changing how plants communicate, respond, and grow. These trends are not just about efficiency or cost savings. They are about building factories that can adapt to disruptions, attract skilled workers, and meet sustainability goals without slowing down production.

In this article, we will look at the biggest industrial manufacturing trends shaping 2025 and beyond, and explore how forward-thinking companies are using them to create safer, faster, and more resilient operations.

AI-Powered Operations Move Beyond Testing

Artificial intelligence has graduated from pilot programs to running actual production lines. When you connect machine data, production schedules, and inventory tracking to smart software, decisions happen faster than human teams can process them. Plants that integrate AI into existing systems see smoother transitions between planning and execution, plus fewer unexpected breakdowns, thanks to predictive models that spot problems before equipment fails.

AI-powered visual inspection systems are also becoming standard on modern production lines as part of modern Industry 4.0 use cases. These systems use high-resolution cameras and machine-learning algorithms to detect even the smallest surface defects in real time — things human inspectors might miss at high speeds. Once a flaw is spotted, the system can trigger automatic adjustments or divert defective products before they move further down the line.

Computer vision systems catch defects the moment they happen, reducing waste and rework. Real-time inspection paired with automatic adjustments improves quality rates and speeds up production cycles. Meanwhile, demand forecasts generated by intelligent systems reduce excess inventory while keeping essential parts stocked, freeing up cash for growth investments.

The technology works best when people embrace it. Smart manufacturers train experienced operators to translate sensor data into practical adjustments and help coworkers adapt to new processes. These "digital champions" speed up adoption across entire facilities by converting technical information into actionable shop-floor improvements. When safety incidents or equipment issues arise, these workers can quickly report problems with photos and details, creating timestamped documentation that helps prevent future occurrences.

Edge devices running AI models directly next to machines process data instantly without network delays. This setup provides major benefits for efficiency and reliability, especially when combined with expanded sensor networks that monitor everything from vibration patterns to temperature variations.

Connected Worker Platforms Support Frontline Teams

Digital platforms are becoming the standard way to keep frontline teams informed, trained, and safe. These systems use mobile devices, wearables, and display screens to deliver step-by-step work instructions right where employees need them, while cloud systems track every action for review later.

On-Demand Remote Expertise

Remote expert assistance lets technicians share live video and get real-time guidance in seconds, turning specialized knowledge into something available on demand.

Smart Skill Tracking and Targeted Training

Smart skill tracking automatically assigns tasks to qualified employees while scheduling quick training sessions before knowledge gaps become problems.

Standardizing Best Practices Across Locations

Standardizing your best practices becomes much simpler when digital work instructions update instantly across all locations. New employees can access training materials, safety procedures, and company policies from day one, while experienced workers receive immediate updates about process changes.

Real-Time Safety Monitoring and Data-Driven Insights

Sensors catch safety issues for real-time monitoring, and every scan, photo, or completed task feeds into reporting systems, enabling data-driven improvements without waiting months for formal reviews.

Common Implementation Challenges and What's Next for Connected Worker Technology

Implementation challenges persist. Older equipment often resists new technology integration, wearable devices can feel uncomfortable during long shifts, and connectivity issues in certain areas can disrupt workflows. Despite these hurdles, adoption continues expanding across manufacturing, logistics, and construction.

Smarter, More Adaptable Automation Across Industries

The next generation promises automated work instruction creation, stronger connections to analytics systems for predictive insights, and interfaces so intuitive that new employees master them within hours. Connected worker technology no longer feels experimental and is becoming the foundation for operational excellence.

Collaborative robots give you easy-to-use automation that adapts to daily production changes instead of creating bottlenecks. Unlike traditional robots locked behind safety barriers, cobots can roll to a new workstation, learn a new task in minutes, and work safely alongside your team. Their simple touchscreen controls and point-and-click programming replace the complex coding that used to take engineering teams days to figure out.

Key Differences from Traditional Industrial Robots

Speed, cost, and space requirements separate cobots from traditional automation. A lightweight robotic arm fits on your existing workbench, plugs into standard power outlets, and starts picking, packing, or tending machines the same day you set it up. Traditional robots still handle heavier loads and move faster, but they need expensive upfront engineering, protective barriers, and lengthy reprogramming when you change products.

Real-World Applications Across Industries

Real manufacturing facilities demonstrate this versatility across industries. Electronics companies use cobots for delicate circuit board assembly, auto parts suppliers load machines without rebuilding production lines, and pharmaceutical companies automate bottle packaging while technicians focus on quality checks. Smaller manufacturers appreciate that cobots cost less to get started, making automation accessible to companies that previously couldn't justify the investment.

The same push for smarter, more adaptable systems is transforming construction. The latest modular-building techniques allow entire sections of a structure to be manufactured in controlled factory settings, then transported and assembled on-site. This reduces weather delays, improves quality control, and shortens project timelines.

Scheduling has also evolved. Generative-scheduling tools create a realistic digital model of your project, taking into account real-world factors like crew availability, equipment, site access, and productivity rates. Then, in minutes, they test hundreds of thousands, or even millions, of “what-if” scenarios. This results in schedules that can cut overruns by 30–50 percent. In some projects, this approach has shaved almost 10 months off the timeline and delivered up to a 12× return on investment. All of this runs through digital control towers that bring together real-time data and 5D BIM simulations, so teams can see the plan in action before work begins.

Finally, performance transparency systems give project owners and contractors real-time visibility into progress, costs, and risks. By centralizing updates and metrics, teams can spot bottlenecks early and address them before they escalate.

Digital Twins Become Living Operating Systems

Digital twins have moved far beyond static models into dynamic systems that learn from every sensor reading and operator action. These living twins update themselves as your plant changes, letting you test modifications in minutes, catch bottlenecks before they slow your line, and schedule maintenance before anything breaks.

Modern twins update automatically when you swap equipment or patch software. Sensors, cloud computing, and artificial intelligence help the twin mirror actual conditions second by second. Modular frameworks let you add new assets without starting over, making expansion much more manageable.

The results show up quickly in measurable improvements. Real-time scenario testing speeds up planning cycles while intelligent insights help you fine-tune line speeds. Predictive dashboards spot wear patterns before breakdowns happen, and some plants even run virtual prototypes overnight to test tomorrow's production run, cutting scrap and avoiding launch delays.

Overcoming Implementation Challenges

Implementation challenges still exist. Connecting legacy equipment takes work, teams need time to trust the model, and scaling from one machine to an entire factory gets complicated. But the direction is clear: modern manufacturing will pair these living twins with human expertise, creating resilient operations that get better every shift.

Private Networks Enable Instant Decision-Making

Private networks and edge computing deliver instant insight by processing data where it's generated — right on your factory floor. These dedicated networks reserve bandwidth exclusively for your facility, eliminating competition from consumer traffic while providing the high-speed, low-delay connections that modern manufacturing demands. Security happens on-premises, keeping sensitive production data and safety information locked down tight.

Edge servers positioned near your equipment process sensor data in real-time, enabling immediate responses that traditional cloud computing can't match. Camera feeds analyzed at the edge catch defects the moment they occur, stopping faulty parts before they move down the line. The same infrastructure powers autonomous vehicles that navigate around obstacles instantly and runs computer-vision safety systems that alert workers the second a forklift enters a restricted area.

The results include shorter cycle times, higher first-pass yields, fewer workplace accidents, and stronger security. You'll also reduce cloud costs since raw images and control signals stay within your facility rather than traveling to distant data centers.

This foundation relies on small base stations that connect devices to core networks, which then route data to edge computing nodes and integrate with existing control systems. This modular approach means adding new production lines or robots doesn't require rewiring your entire operation.

Supply Chains Rebuild Around Better Information

Global disruptions taught manufacturers that keeping minimal inventory isn't enough anymore. You need better information as much as you need backup parts, and that information increasingly comes from connected systems. Intelligent planning systems now analyze past demand and market trends to optimize inventory levels, preventing both stockouts and excess inventory while giving planners a clearer picture of potential risks.

Advanced digital twins take this visibility further by running scenarios for suppliers, shipping routes, and plant capacity. You can test different situations, such as port closures, material shortages, and unexpected order spikes, and see the impact before placing any orders.

Real-time connections make everything faster. Dedicated networks deliver sensor data from incoming shipments and production lines instantly, so delays or quality problems show up right away instead of days later in reports. This creates supply chains that catch problems early shift resources quickly, and keep customers happy even when global logistics face disruptions.

Sustainability Becomes Measurable and Profitable

Sustainability became a part of the production dashboard. You now track carbon, energy, and waste with the same attention you give cycle time, turning environmental goals into numbers that move profits. Real-time resource monitoring built into intelligent systems watches air quality, energy usage, and chemical emissions as you work, letting you cut waste before it hits the budget.

The fastest gains come from four key areas:

- Energy analytics that flag idle motors and leaking air lines before they drain your budget

- Electrification of heat-intensive processes where it makes sense

- Switching to recycled or bio-based materials when quality allows

- Designing circular flows so scrap becomes next-shift feedstock instead of landfill waste

Advanced digital twins make those improvements tangible. Because twins run scenarios in minutes, you can test a new material mix or altered line speed without gambling on the shop floor. Customer audits and investor scorecards add urgency — instead of vague pledges, you can share real-time dashboards that map every kilowatt and kilogram to a project owner.

Modern frameworks blend resilience, human-centered design, and environmental goals into one operating model. As a result, sustainability shifts from a cost center to a measurable competitive edge that wins contracts and talent.

Cybersecurity Becomes Essential for Operations

Connecting every machine, sensor, and mobile device gives you the agility you need, but it also puts cybersecurity front and center for executives. The same networks that power intelligent tools and collaborative robots now carry production-critical data. A breach can shut down production just like a broken machine.

Changes are already happening on the shop floor. Private networks keep your data secure with encryption and local verification, isolating it from public carriers and reducing security risks. Edge servers process analytics right next to your machines, so sensitive process data stays local instead of traveling across the internet. These protections make security a built-in feature of your operations, not an afterthought.

Leadership teams are investing in these upgrades because downtime costs money and reputation damage is hard to fix. Dedicated network allocations make it easier for executives to justify investments that strengthen defenses while improving performance. Real-time monitoring of robots and vehicles over secure connections means cybersecurity becomes essential for productivity, safety, and compliance.

Equipment-as-a-Service Changes How You Buy Machines

The same sensors and intelligent tools guiding your predictive maintenance are opening doors to a different way of buying equipment. Instead of purchasing machines outright, you pay for what they produce or how much they run. When manufacturers can track vibration, temperature, and runtime through connected dashboards, they can guarantee performance and fix problems before they happen.

This shift makes financial sense for both sides:

- You get predictable monthly costs instead of large upfront purchases, plus fewer surprise breakdowns on the shop floor.

- Equipment makers get steady income and stronger customer relationships.

Smart predictive maintenance cuts unplanned downtime so much that suppliers feel comfortable promising specific uptime levels.

Connected systems let vendors monitor your equipment remotely, adjust settings, and push updates without sending technicians. This turns service from a cost center into consistent revenue. Systems stream performance data back to manufacturers, helping them refine their designs and prevent issues before they impact your production.

The main challenges are business-focused rather than technical. Companies need to find pricing that fairly shares risk, help finance teams adjust from big one-time purchases, and train field staff to think more like customer service representatives. As more equipment comes ready with sensors, paying for results instead of machinery is becoming the standard conversation.

Workforce Development Focuses on Digital Skills

A tight labor market means every worker needs to do more than before. Manufacturers are responding by giving their teams digital tools that help them work smarter, not just harder. This means crews get intelligent insights to guide decisions, step-by-step digital instructions for complex tasks, and instant access to expert help when problems come up.

Targeted Digital Skills Training

This approach starts with targeted training. Many plants now have experienced workers who help bridge the gap between floor teams and technical staff. These champions speed up adoption of new systems and bring shop-floor feedback back to engineers. When machines flag an issue, these champions help coworkers read dashboards or adjust settings, turning every alert into a teaching moment instead of a crisis.

Connected Platforms Streamline Onboarding

Connected platforms now deliver instructions and safety checks directly to tablets or screens, cutting onboarding time and making sure best practices stay consistent across all shifts. Real-time remote help lets experienced technicians guide newer workers through complex repairs using live video, getting jobs done right the first time. Regular pulse surveys help managers understand how well new processes are working and where additional support might be needed.

Communication Tools Keep Everyone Connected

None of this works without solid communication that reaches everyone. Plants invest in reliable networks and simple messaging tools so updates reach every station instantly, regardless of language barriers or technology comfort levels. This matters more than ever when your workforce includes both newer employees and experienced veterans who may prefer different communication styles. When you pair people with easy-to-use technology and keep everyone connected, you can handle labor shortages, preserve valuable knowledge, and boost productivity without overwhelming your team.

Keep Your Manufacturing Team Connected During Digital Transformation

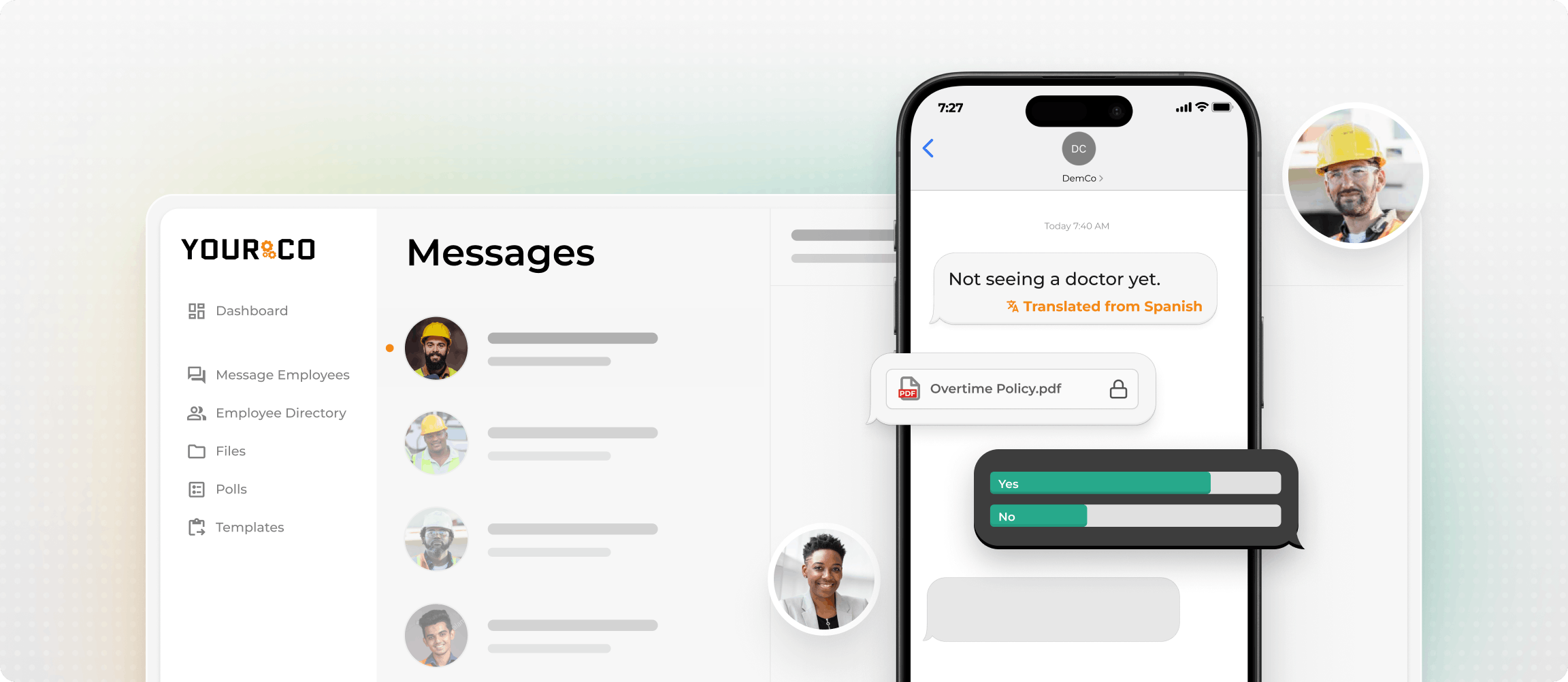

Yourco's SMS platform aligns perfectly with these emerging trends, offering purpose-built features that support digital transformation without requiring additional technology investments.

While factories deploy cobots and AI systems, Yourco ensures everyone stays informed about these changes without needing specialized devices or internet access. The platform's 98% read rate within 90 seconds means critical updates about equipment changes, safety protocols, and production targets reach workers immediately.

For multinational manufacturing operations, Yourco's AI-powered translations for 135+ languages directly supports the industry trend toward diversity and inclusion in the workforce. This feature helps maintain consistent communication across language barriers, crucial when implementing complex digital twin systems or training teams on new automation.

Yourco's integration capabilities align with manufacturing's shift toward connected systems. The platform links seamlessly with HRIS and equipment management systems, automatically routing alerts and updates to the appropriate teams. This means maintenance notifications, safety alerts, and production changes flow directly to workers' phones in real-time, supporting the immediate decision-making that modern manufacturing demands.

Try Yourco for free today or schedule a demo and see how our communication platform complements your manufacturing technology roadmap.

Frequently Asked Questions

How does Yourco support multilingual manufacturing teams during digital transformation?

Yourco's AI-powered translation capabilities automatically convert messages to any of 135+ languages based on each worker's preference. This means your entire workforce receives the same critical information about new equipment, safety protocols, or process changes in their native language. No separate translations or duplicate messages needed. Managers send one message, and workers read it in Spanish, Vietnamese, Arabic, or dozens of other languages without any extra steps, ensuring everyone understands important safety alerts and training information during technology rollouts.

Can Yourco integrate with manufacturing systems to automate operational communications?

Yes, Yourco integrates with over 240 HRIS and production management systems to automate critical communications. When a machine needs maintenance, production schedules change, or safety incidents occur, Yourco can automatically send notifications to the right team members without manual intervention. This integration capability means maintenance alerts, schedule changes, and safety notifications flow directly to workers' phones in real-time. The platform also captures and logs all communications for compliance and audit purposes, creating timestamped records of critical operational updates.

Do connected worker platforms require a complete IT overhaul?

Not at all. Modern platforms work with your current systems and pull data through standard connections. Most plants start with tablets on one production line, add digital work instructions, then connect to their main systems later. The biggest challenge is usually getting your team comfortable with the new tools, showing them how digital instructions and remote help make their jobs easier, not harder.

How can I ensure my frontline workers stay informed during digital transformation?

The key is using communication methods that actually reach non-desk workers. While email and apps often get ignored, SMS messages achieve 98 percent read rates within 90 seconds. Choose a platform like Yourco that works on any phone, supports multiple languages, and integrates with your existing systems to automatically send updates about equipment changes, safety procedures, and training requirements.