10 Proven Strategies For Using AI to Boost Manufacturing Productivity

Tighter delivery windows, rising material costs, and customers who won't tolerate defects or delays create constant pressure on manufacturers. Meanwhile, early AI adopters have already captured productivity gains with predictive models that flag machine failures before they halt production, vision systems that catch microscopic defects, and algorithms that cut hours from planning cycles.

But technology alone can't move parts or people. This guide covers ten practical AI strategies that tackle everyday manufacturing pain points. Our approach pairs advanced analytics with straightforward communication, helping you turn data into action and keep productivity climbing in 2025 and beyond.

Why Traditional Manufacturers Struggle to Adopt AI and Where to Start

Many manufacturers know AI could help them cut downtime, reduce waste, and speed up production, but getting started often feels risky. These are operations built on stability, consistency, and proven processes, so it's no surprise that leaders in traditional industries approach new technology with caution.

Even when leadership sees the value of AI, they face real barriers:

- Legacy equipment that lacks modern sensors

- Disconnected teams spread across shifts and sites

- Language barriers that slow communication

- Skepticism from experienced staff who’ve seen tech fads come and go

- Poor communication infrastructure that turns fast AI insights into slow human response

The key to getting started isn’t deploying the most advanced system, but building a foundation that ensures your people can act on insights the moment they appear.

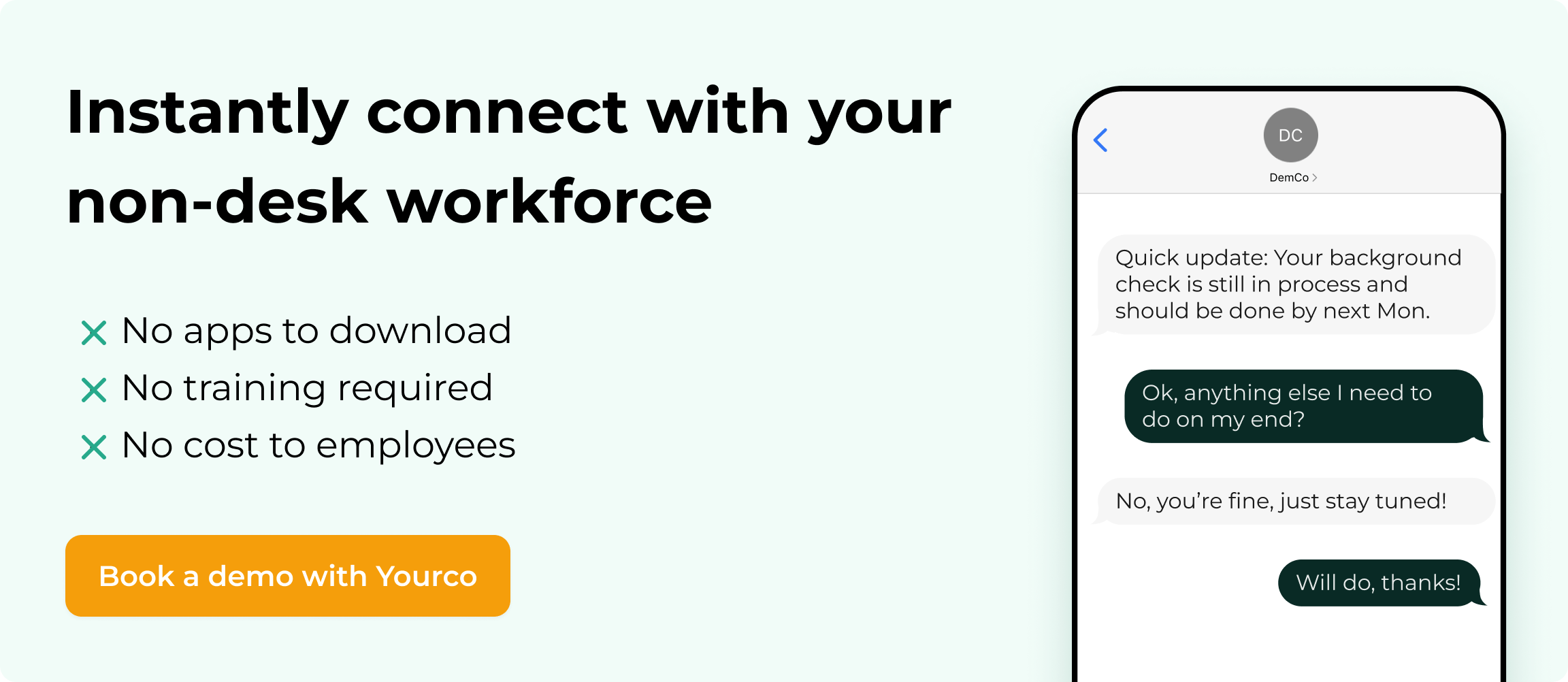

Start With Modern Communication

Before AI can improve productivity, you need to make sure insights actually reach the people who can act on them. Yourco helps you modernize workforce communication without apps, downloads, or training. Messages, such as maintenance alerts, safety warnings, or shift schedule changes, are sent directly to employees’ phones via SMS, in their preferred language. This builds a fast-response environment where AI insights can trigger real action.

Once you have reliable, two-way communication in place, everything else gets easier:

- Predictive maintenance alerts reach the right technician instantly

- Quality issues trigger real-time feedback loops between AI, supervisors, and frontline workers

- Shift changes and job reassignments happen fast when priorities change

Starting small, with a low-risk investment in communication, helps traditional teams build confidence. From there, it's easier to scale into smarter systems, because you’ve already solved the biggest AI barrier: getting critical information to the right person, fast.

With that communication foundation in place, you’re ready to put AI to work. The strategies that follow focus on real-world applications that help manufacturers improve productivity, prevent waste, and respond faster — all while keeping workers informed and engaged.

1. Predictive Maintenance for Reduced Downtime

Imagine that your production line warns you hours, or even days, before a critical motor fails. AI-powered predictive maintenance makes this possible by analyzing live sensor data alongside years of equipment history to spot trouble before it strikes. These systems identify patterns that predict when each component will likely fail, giving you time to plan repairs during scheduled downtime.

The benefits extend far beyond preventing breakdowns. Scheduled maintenance during planned stops helps equipment last longer, reduces costly overtime, and eliminates the scramble to find replacement parts when something fails unexpectedly. Smart systems even connect maintenance predictions with your inventory management, so you order spare parts exactly when needed rather than stockpiling expensive components.

However, these insights only matter if they trigger the right action. Once AI detects patterns like temperature spikes or vibration changes, it can help you schedule maintenance before failure hits. Use SMS alerts about upcoming service windows, part replacements, or temporary shutdowns — so your team stays informed and your floor stays safe. Clear, timely communication helps everyone prepare and prevents small issues from turning into costly downtime.

2. Real-Time Quality Control and Defect Detection

AI-powered cameras can watch every product on your line, catching defects that human inspectors might miss during long shifts or busy periods. These systems spot cracks, color issues, or alignment problems with accuracy, working around the clock without breaks or distractions.

Beyond catching bad parts, AI can now help you understand why defects happen in the first place. Smart sensors analyze production data in real time, connecting patterns to root causes so you can fix problems before they create more waste.

When the system detects an issue, operators can immediately report the problem details via SMS, including photos of the defect or equipment malfunction. This creates instant, time-stamped documentation that captures not just what went wrong, but the conditions surrounding the failure, such as:

- Shift time

- Machine settings

- Environmental factors

- Operator observations that automated systems might miss

Instead of waiting for end-of-shift paperwork or relying on memory hours later, you get real-time incident reports that feed directly back into your AI system. Over time, this human-generated data helps the AI identify more subtle patterns and improve its predictive accuracy, turning every quality issue into valuable intelligence for preventing future problems.

3. Intelligent Production and Supply Chain Optimization

External disruptions don't have to catch you off guard. AI transforms your operation from reactive guesswork into proactive planning by analyzing factors beyond your direct control, such as supplier performance, market conditions, and transportation networks, to predict future challenges with remarkable accuracy.

The system continuously processes external data sources:

- Market trends and economic indicators affecting material costs

- Supplier lead times and reliability scores

- Transportation delays and carrier performance

- Global supply chain disruptions and geopolitical factors

- Customer demand fluctuations and seasonal patterns

AI algorithms identify patterns in external conditions that humans typically miss. For example, the system might notice that a specific supplier consistently delivers three days late during month-end periods, or that transportation costs always spike when fuel prices exceed certain thresholds. Using these insights, AI automatically adjusts procurement strategies and supplier relationships.

When the system detects potential external disruptions, like a key supplier showing signs of delay based on historical patterns, it suggests alternative suppliers or expedited shipping options. The algorithms weigh factors like cost, delivery time, and supplier reliability to recommend the most cost-effective solution before problems cascade through operations.

Companies that utilize intelligent supply chain management typically reduce carrying costs while maintaining fill rates of 99% or higher by better anticipating and responding to external market forces.

4. Effective Resource Allocation and Scheduling

AI-powered systems optimize the resources you directly control — machines, materials, and people — by scanning real-time internal data to deliver optimal production plans within seconds.

Machine learning models evaluate thousands of internal combinations to assign tasks where they work best:

- Machine capacity and current status

- Staffing levels and skill sets

- Available materials and inventory locations

- Production priorities and deadlines

- Equipment maintenance schedules

When rush orders arrive or equipment breaks down, the system immediately recalculates using your available internal resources and delivers an updated schedule so production continues without interruption.

Manufacturers implementing intelligent internal scheduling typically see:

- Schedules that adapt to real-time internal changes

- Shorter changeovers through smarter job sequencing

- Higher OEE as machines run more and wait less

- Reduced overtime costs through automatic shift balancing

These improvements only work when you have the right people in the right places. When AI generates an optimal schedule but three operators call in sick, SMS communication helps you quickly identify who's available for overtime or cross-training opportunities. Workers can respond to shift coverage requests instantly, letting you maintain production flow instead of scrambling to fill gaps or running understaffed lines that slow everything down.

5. Energy Consumption and Sustainability

Cutting your energy bill starts with knowing exactly where the power goes. AI platforms review your meter readings, sensor data, and production schedules to spot hidden energy drains and recommend fixes. In process plants, AI models track how much electricity, steam, and compressed air each step uses, then predict the most efficient settings for the next shift.

Once the system understands your patterns, it shows you valuable benefits:

- It automatically adjusts equipment settings to use only the power needed for current production

- It moves energy-heavy jobs to off-peak hours when rates are cheaper

- It puts machines into low-power mode between cycles instead of full standby

- It sends instant alerts when energy use jumps above normal levels

Lower energy use also means lower emissions, helping you meet the sustainability goals many manufacturers face. The key to making these savings stick is getting energy alerts to the right people fast. Whether through text messages, plant displays, or two-way radios, operators need to see warnings the moment they appear so they can adjust settings right away.

6. Workforce Augmentation and Training

AI systems study how each person performs their tasks and deliver quick, targeted lessons right when they're needed. Think of an AR display that shows the exact torque setting, or a two-minute VR practice session before a challenging shift starts.

The best part is that these tools learn from what actually happens on your floor. When someone masters a technique or makes a mistake, the system captures that knowledge and shares it across your entire operation. Veteran workers aren't slowed down by basic reminders, while new hires get the extra guidance they need to succeed safely.

Many workers worry that AI will replace them, but smart training tools prove the opposite. When employees see fewer errors in their work and feel more confident in their routines, resistance fades quickly. They realize AI removes the guesswork that makes their jobs harder, not the jobs themselves. To make training truly accessible, deliver instructions and feedback through SMS, so workers can check quick updates between shifts without downloading apps or learning new systems.

7. Demand Forecasting and Production Alignment

Planning production around guesswork leads to expensive mistakes. AI demand forecasting changes that by pulling data from sales history, promotions, weather patterns, and real-time supply chain updates to predict what customers will actually buy. Instead of scrambling when orders spike unexpectedly, you can plan production runs, secure raw materials, and schedule shifts weeks ahead.

AI forecasting systems can also catch patterns that slip past human analysis, such as regional search trends signaling demand shifts or subtle changes in supplier lead times, helping you avoid both excess stock and costly stockouts.

However, accurate forecasts mean nothing if they sit in a dashboard. Production planners, purchasing teams, and logistics coordinators need those insights immediately through mobile-friendly alerts and simple dashboards to ensure everyone works from the same numbers, turning predictions into coordinated action across your entire operation.

8. Employee Feedback Analysis and Sentiment Tracking

Regular pulse surveys generate valuable data, but manually analyzing hundreds of responses across multiple locations quickly becomes overwhelming. AI transforms scattered feedback into clear patterns that help you address issues before they impact productivity or safety.

Smart analytics can process survey responses, participation rates, and communication patterns to identify trends across your operation. The system might detect that safety concerns spike at specific locations during certain shifts, or that engagement scores consistently drop before peak production periods. These insights help you target interventions where they'll make the biggest difference.

AI-powered sentiment analysis goes beyond simple survey scores to understand the tone and urgency behind employee responses. When workers mention equipment problems, scheduling conflicts, or safety concerns, the system flags these issues by priority and location, giving you a clear picture of what needs immediate attention versus long-term planning.

The most valuable insights come from connecting feedback patterns with operational data:

- Which locations report the highest stress levels during overtime periods?

- Are safety complaints concentrated around specific equipment or shifts?

- How does communication frequency affect employee satisfaction scores?

- Which teams consistently participate in feedback requests versus those who don't?

These insights only create value when they reach the right people quickly. When AI identifies concerning trends, like declining safety sentiment at a specific plant, managers need immediate alerts so they can investigate and respond before small issues become bigger problems. This turns routine employee surveys into an early warning system for operational challenges.

9. AI-Enhanced Safety Monitoring and Incident Prevention

Workplace accidents happen in seconds, but the warning signs often build up over time. AI-powered safety systems analyze patterns from multiple data sources, such as equipment sensors, environmental monitors, and worker-reported incidents, to identify risks before they lead to injuries.

Smart cameras and sensors can detect unsafe conditions, such as blocked emergency exits, missing personal protective equipment, or hazardous machine vibrations. However, the real power lies in connecting these automated alerts with human observations. When workers report near-misses, equipment concerns, or safety hazards via SMS, AI systems analyze these reports alongside sensor data to paint a complete picture of workplace risks.

This combination reveals patterns that neither humans nor machines would catch alone:

- Equipment that shows stress signals hours before visible problems appear

- Environmental conditions that correlate with higher incident rates

- Specific locations or shifts where safety concerns cluster together

- Training gaps that increase risk for certain tasks or teams

The system gets smarter over time by learning from every incident report, near-miss, and safety observation. When AI identifies elevated risk conditions, such as temperature spikes near flammable materials or repetitive strain patterns in specific work areas, it can instantly alert the relevant supervisors and safety personnel.

Workers benefit because they receive immediate feedback about potential hazards in their area, while safety managers get early warnings about systemic issues that need attention. Instead of waiting for monthly safety meetings to discuss problems, teams can address concerns in real-time, creating a more responsive safety culture where everyone stays protected and productive.

10. AI-Powered Translations for Multilingual Manufacturing Teams

Manufacturing facilities often employ workers who speak different languages, creating communication barriers that can impact both safety and productivity. Traditional translation services are too slow for real-time operations, while expecting everyone to communicate in a single language excludes valuable team members and creates compliance risks.

AI-powered translation technology solves this by instantly converting critical messages into each worker's preferred language. When a safety alert needs to reach your entire facility, the system automatically translates it into Spanish, Vietnamese, Mandarin, or any of the 135+ languages your workforce might speak. This ensures everyone receives the same important information simultaneously, regardless of their primary language.

The technology goes beyond simple word-for-word translation by understanding manufacturing context. AI systems learn industry-specific terminology, safety protocols, and equipment names, so translations maintain accuracy even for technical instructions. When a maintenance alert mentions "hydraulic pressure low on Line 3," the translation preserves both the technical meaning and the urgency.

Real-time translation creates several key benefits:

- Safety instructions reach every worker in their native language

- Training materials become accessible to diverse teams

- Incident reporting captures details without language barriers

- Compliance documentation meets multilingual requirements

The most effective translation systems work seamlessly with existing communication workflows. Workers can report issues, ask questions, or confirm task completion in their preferred language, while supervisors receive everything in their chosen language. This removes the hesitation that often prevents non-native speakers from participating fully in safety protocols or process improvements.

When language stops being a barrier, you unlock the full potential of your diverse workforce while maintaining the clear communication that modern manufacturing demands.

Turn AI Insights into Action with Yourco

AI can detect defects, forecast demand, or flag equipment issues — but unless those insights reach the right people instantly, nothing changes. Yourco ensures important and urgent alerts get through fast with SMS-based messaging built for the realities of the factory floor. Messages go directly to technicians, supervisors, or logistics staff — no apps, no email, no training required.

Yourco supports two-way messaging, real-time confirmations, and automatic translation into 135+ languages, so every team member, regardless of role or language, gets clear, actionable instructions. This keeps AI feedback loops fast and effective while ensuring no one is left out of the conversation.

You can also personalize messages by role, shift, or location to avoid confusion and cut through noise. With unlimited messaging and message history, teams stay aligned, responsive, and audit-ready.

Try Yourco for free today or schedule a demo and see the difference the right workplace communication solution can make in your company.

FAQs

Do workers need smartphones to get updates?

No. Any phone that can receive a text message works, making sure everyone stays in the loop.

Can Yourco handle multi-language crews?

Yes. Yourco offers an AI-powered translation feature that instantly translates any message into 135+ languages and dialects, helping every crew member understand exactly what needs to happen next.

Can I track who received and responded to an alert?

Yes. Yourco tracks message delivery status and responses in real-time, so you know who received the alert and who replied — critical for time-sensitive tasks like equipment issues or schedule changes. While SMS doesn’t support read receipts, Yourco’s system can confirm successful delivery and flag any undelivered messages, helping managers follow up as needed.

Is there a limit to the number of messages I can send?

No. Yourco offers unlimited messaging, even on the free plan, so you can communicate freely with your entire team without worrying about extra fees.