Lean Manufacturing Principles for Waste-Free Efficiency

Lean manufacturing strips away waste so you can deliver exactly what customers want, when they want it. This systematic approach spots and removes any step, material, or motion that doesn't add value for the customer. Instead of churning out big batches for stock, you fine-tune processes to flow smoothly and respond quickly to real demand. Many companies, from aerospace to food processing, have adopted this same mindset to stay competitive.

This guide walks you through the past, present, and future of lean manufacturing — from its origins at Toyota to its global expansion and digital transformation. You’ll see how lean principles reduce lead times, boost product reliability, engage teams, and sharpen your competitive edge. Best of all, these are changes you can start making today, no massive budget or complex tools required.

The Evolution of Lean Manufacturing: From Toyota to Global Transformation

Lean manufacturing began as Toyota's post-World War II survival strategy and evolved into the Toyota Production System (TPS). Toyota engineers Taiichi Ohno and Shigeo Shingo studied American supermarket systems and Ford's assembly lines, then refined these concepts to eliminate waste while maintaining quality. By the 1970s, Toyota was consistently outperforming American automakers, sparking global interest.

This success triggered widespread adoption across industries. The 1980s brought lean to electronics and industrial companies like Motorola and GE, spawning Six Sigma and other quality initiatives. As lean principles proved their versatility, the 1990s saw expansion into service industries, with Southwest Airlines applying waste reduction to flight operations.

These industry pioneers demonstrated lean's adaptability beyond manufacturing. Ford's transformation exemplifies this evolution: after quality struggles in the 1980s, Ford embraced lean in the 1990s, restructuring global operations with value stream mapping and standardized work. The company achieved substantial reductions in warranty costs and dramatically shortened vehicle development timelines. Today, Ford continues this evolution by integrating digital twins and predictive analytics with traditional lean tools.

Similarly, P&G's journey in the early 2000s shows the extensive scope of lean principles. Through its Organization 2005 initiative, P&G standardized workflows, improved changeover flexibility in detergent plants, and enabled greater product variety without raising costs. As lean practices spread into product development, concept-to-market timelines shrank dramatically. Brands like Olay now launch products faster than competitors while maintaining premium quality.

Today's global transformation builds on these decades of innovation. What started as Toyota's local solution has become the foundation for modern Industry 4.0 initiatives, sustainable manufacturing, and digital-first operations worldwide. The principles remain constant, but the tools and scale continue expanding.

The 5 Core Principles of Lean Manufacturing

Lean thinking rests on five fundamental ideas first captured by James Womack and Daniel Jones: value, value stream, flow, pull, and perfection. Following these principles, in that order, helps you build a clear roadmap. Every hour of labor, every square foot of space, and every dollar of material gets turned into something your customers want — and nothing they don't.

Master these fundamentals and you create a factory that turns customer needs into finished goods with almost no waste.

1. Value: Start with What Customers Will Gladly Pay For

When you focus resources on what customers truly value, you avoid wasting wages, materials, and time on work no one appreciates.

Begin by asking, "What does the customer actually want?" In lean manufacturing, that answer frames every decision that follows. You can uncover this answer with quick pulse surveys, short interviews, or informal feedback calls.

For example, a maker of custom bike parts can learn through a five-question survey that riders care more about fast delivery than glossy packaging. As a result, the company shifts labor from box design to order turnaround, boosting customer satisfaction while cutting costs.

2. Value Stream: Map Every Step, Scrap the Ones That Don't Add Value

Once you know what matters, trace your product's journey from raw material to loading dock. This step doesn’t have to be high-tech. Gather a small cross-functional team, some sticky notes, and lay out the process on a wall. You don't need fancy software to see that steps adding cost but no value need to go.

This informal value stream map shows where parts wait, move, or loop back for rework. Teams often identify quick wins within an hour, such as combining two inspection points or placing a gauge at the machine instead of in a distant quality lab.

3. Flow: Keep Work Moving in A Smooth, Unbroken Line

After cutting the waste, rearrange what remains so work can travel without stops. Many small plants create "mini lines" or cellular layouts where machines and workstations sit side by side in processing sequence. This change alone slashes travel time and mix-ups.

Or maybe you can shrink batch sizes. Instead of running 1,000 pieces before changeover, try 200. Smaller lots shorten lead time and reveal problems sooner. Flow also depends on flexible people, so cross-train operators to handle multiple tasks. When a person from machining can jump into assembly during a rush, you prevent the bottleneck that used to stall orders.

4. Pull: Make Only What The Next Step Asks For

Flow works great, but it collapses if you produce ahead of demand. A pull system fixes this by letting real consumption trigger production. The easiest way to start is with a two-bin Kanban: when the first bin of screws at a workstation empties, its attached card signals the stockroom to refill it. Until that card moves, no screws get made or bought.

This simple control also frees cash tied up in inventory piles and clears valuable floor space — huge wins for shops where every square foot counts.

5. Perfection: Treat Improvement as A Daily Habit

Toyota calls it Kaizen: the relentless hunt for a better way. You don't need week-long workshops or consultants to practice it. Schedule a 30-minute "quick fix" session each Friday. Let operators suggest small changes, pick one, test it, and measure results on Monday.

You can also send out a weekly pulse survey via SMS — a virtual suggestion box that makes it easy for workers to share ideas in real time, even on the floor. Just make sure to post wins so everyone sees their input turning into action. Small and mid-sized manufacturers have shorter chains of command, so you can approve and implement ideas in days rather than months.

The 8 Types of Manufacturing Waste

Spotting waste is the fastest way to free up cash, floor space, and time. Some lean manufacturing experts use TIMWOOD, an acronym for the types of waste: Transportation, Inventory, Motion, Waiting, Overproduction, Overprocessing, and Defects.

Some have redubbed this acronym TIMWOODS, which includes 'Skills/Talent' as the eighth waste. Identifying each one is the first step toward chasing waste out of your plant for good.

Transportation: Unnecessary hauling of parts or tools burns fuel and risks damage. Signs that you have transportation waste include forklifts criss-crossing the floor or finished goods zig-zagging between buildings. Lay out workstations in U-shaped cells, store materials at point of use, and combine small moves into one milk-run route. Tighter layouts alone can significantly reduce travel distance without the need for new equipment.

Inventory: Extra raw material, work-in-process, or finished stock are often the first visual clues that you’re wasting capital. Overflowing racks of product and outdated parts hide process problems and gather dust. Using just-in-time deliveries, safety-stock calculators, and frequent cycle counts helps you right-size inventory.

Motion: Over time, unnecessary movements sap productivity. For example, when operators stretch, twist, or hunt for tools, the excess motion can lead to fatigue or injuries that increases call-offs. Tightening processes by shadow-boarding your tools, keeping frequently used items at waist height, and designing fixtures that load in one step can cut cycle times and improve workplace safety simultaneously.

Waiting: When people and machines stand idle, they’re adding zero value while still collecting wages and increasing power bills. Common causes include long changeovers, unbalanced staffing, and missing materials. A quick plant walk will reveal operators hovering near idle presses or forklifts queued for loading. Cut waiting by staggering start times, cross-training staff, and scheduling preventive maintenance outside production hours.

Overproduction: Producing more than what’s needed for the next step or the customer wastes money, hides problems, and creates clutter. Worse still, it sets off other kinds of waste like inventory and transportation. Swap big batches for smaller lots and use Kanban cards or other pull signals so each area produces only when downstream workstations are ready.

Overprocessing: Polishing a hidden surface or adding inspections no customer asked for piles on cost without boosting value. Trace each step back to the customer's actual requirement. If it doesn't satisfy that need, eliminate or simplify it. Lightweight gauges, combined operations, or automated data capture may replace redundant paperwork and double checks.

Defects: When it comes to defects, you’re draining profit twice: once to make it, again to fix or toss it. Catching errors where they happen prevents costly downstream fixes. Look for recurring repairs, customer returns, or piles of scrap near machines. Simple mistake-proofing devices and real-time gauges let operators stop a problem before it spreads.

Talent: Non- or underutilized talent represents a missed opportunity when creative problem-solvers spend the day fetching parts or copying paperwork. Why? You’re paying for skills you never use. Invite operators to daily improvement huddles, rotate them through improvement events, and post suggestion boards that get swift follow-up. Recognition for ideas, such as free pizza, a shout-out, or small bonuses, keeps engagement high and turns every employee into a quality inspector.

Beginner Tools to Apply Lean Manufacturing Principles

You don't need a massive budget to get started with lean processes. These five tools give you quick wins that free up space, shorten lead times, and engage your crew without expensive software or machinery. Over time, you’ll make these practices a daily habit instead of a one-time project.

1. 5S Workplace Organization System

To get started, you really just need one tool, and that’s usually 5S. This foundational process is all about organizing your workspace to boost efficiency, effectiveness, and safety. It's a system that helps you keep everything in its place and your work area tidy. This way, you can get your job done without wasting time or risking injury.

The process is straightforward:

- Sort what you really need

- Set items in order so anyone can find them

- Shine to keep problems visible

- Standardize the routine

- Sustain the habit every day.

A short "sort-and-shine" blitz in one work cell can uncover missing tools or safety risks within hours. Add simple floor tape, photo labels, and a weekly audit checklist to keep the gains visible and permanent.

2. Kanban

Kanban turns each part bin or job ticket into a signal that tells the previous step, "Make one more." A whiteboard and colored cards are enough to start. Map your current steps, set a work-in-progress limit for each column, and meet at the board daily to move cards and fix bottlenecks. Since you only restock when a card reappears, this visual system drops your inventory and exposes flow problems fast.

3. Just-In-Time (JIT) production

Just-In-Time (JIT) production follows the heartbeat of manufacturing efficiency:

- Produce what's needed

- When it's needed

- In the amount needed

For a small shop, that can be as simple as moving from weekly to daily schedules and pairing each workstation with a small buffer rack that holds only a few hours of demand. Expect some hiccups, such as late supplier deliveries or machine breakdowns, but use these roadblocks as a guide to the next fixes you need to make.

4. Kaizen

Kaizen means continuous, everyday improvement through focused events. A simple two-day kaizen event with a mixed team of operators, maintenance, and admin staff can dramatically improve processes. It usually starts with walking the line, then brainstorming problems, testing quick changes, and documenting new standards. Even a modest idea, such as moving a frequently used tool closer to the point of use, can shave minutes off every cycle and show your team that their ideas matter.

5. Value Stream Mapping

Value Stream Mapping helps you see the whole journey before you rush into changes. Sketch a product's path from order to shipment using sticky notes on a wall to mark each step, its cycle time, and any waiting. This simple map often reveals hidden queues or redundant checks you can eliminate immediately. Finish by drawing a "future state" map that shows how the flow should look after your next round of improvements.

The Future of Lean Manufacturing: Digital Integration and Sustainability

Lean manufacturing continues evolving as digital technologies reshape how we eliminate waste and optimize flow. The integration of Industry 4.0 technologies with traditional lean principles creates unprecedented opportunities for efficiency gains.

Digital Technologies Transforming Lean

- Smart sensors and IoT devices provide real-time data streams that make waste visible instantly, replacing weekly reports with immediate visibility into machine downtime, quality variations, and bottlenecks

- Predictive maintenance algorithms identify potential equipment failures before they create waiting waste, while machine learning optimizes changeover sequences

- Digital twins allow companies like Siemens and Boeing to create virtual replicas of production systems, testing improvements digitally before physical implementation

- AI-powered systems identify patterns across thousands of processes simultaneously, spotting waste human observers miss—GE uses AI to analyze jet engine manufacturing data, identifying micro-inefficiencies that save millions

Sustainability Integration

- Traditional waste elimination naturally aligns with environmental goals, but modern lean practitioners actively pursue both cost reduction and carbon footprint reduction

- Energy waste, material waste, and time waste often interconnect, creating opportunities for simultaneous environmental and financial improvements

Workforce Evolution

- Remote monitoring capabilities allow experienced lean practitioners to guide improvements across multiple facilities without travel

- Digital collaboration tools enable global teams to share best practices instantly

- Mobile apps put lean tools like 5S audits and Kaizen suggestions directly into workers' hands

Future Outlook

- Quantum computing and advanced analytics promise to optimize entire supply networks using lean principles

- Companies will apply lean thinking to global value streams, eliminating waste across suppliers, manufacturers, distributors, and customers simultaneously

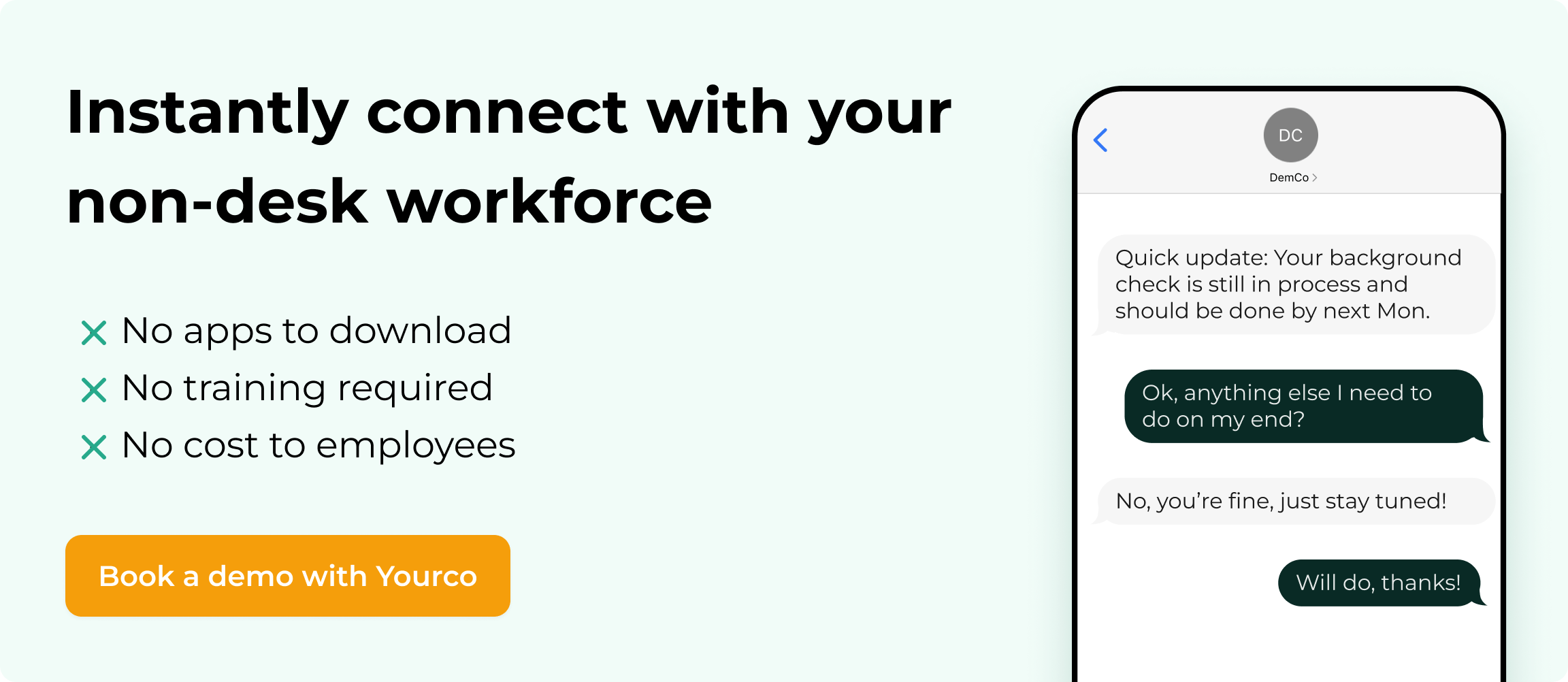

Keep Your Communication Lean with Yourco

Small steps build momentum and show your team that progress beats perfection every time. Yourco helps keep that momentum going with quick SMS updates about daily improvements, employee suggestions, and project completion — no apps or training needed.

You can send daily updates to share before-and-after photos from 5S improvements, highlight quick wins, or remind teams of the day’s lean focus. If someone spots a better way to organize a space or eliminate a step, they can text it in immediately — Yourco supports real-time idea collection, including anonymous feedback, so no insight goes unheard.

Lean only works when every voice counts, which is why Yourco offers built-in translation to over 135 languages. Whether you’re explaining a new standard or updating cleaning procedures, our platform ensures every team member gets the same clear message in a language they understand. You can also link out to documents, checklists, or training videos — Yourco turns these into SMS-friendly links that open instantly, even on basic phones.

Try Yourco for free today or schedule a demo and see the difference the right workplace communication solution can make in your company.

Frequently Asked Questions

What if my team is already stretched thin?

Try a 5S session or waste walk first — each takes under an hour and actually saves time by clearing out confusion and clutter.

Do I need special software to create a value stream map?

Not at all. Sticky notes and a marker work great for your first map. You can always upgrade to software later if you need deeper analysis.

How does Yourco support lean projects?

Yourco sends quick reminders, collects team feedback, and keeps everyone updated through simple text messages — no downloads or logins required. This keep process improvements visible and moving forward.