The True Cost of Miscommunication in the Workplace: Financial and Safety Impacts

Every operation runs on communication, but when the message does not land, the damage multiplies. One missed update can stall production, trigger overtime, or put workers in harm’s way. These are not rare slip-ups. They happen daily across manufacturing floors, construction sites, and logistics hubs where crews depend on shift briefings, radios, or word of mouth.

The financial fallout is staggering. Some businesses lose millions each year because instructions get twisted, policy changes arrive late, or safety alerts never reach the right people. Yet the hidden costs often stay off the books, showing up as lost time, high turnover, compliance failures, and preventable accidents.

This article unpacks those costs and shows how they quietly erode budgets, trust, and safety. It also provides practical steps to keep information flowing clearly and consistently, especially for non-desk teams who cannot rely on email but face the highest risks when communication breaks down.

Recognize the Hidden Price of Poor Communication

Workplace communication failures appear in various ways: vague instructions, late updates, missing channels, language gaps, and cultural misunderstandings.

You've likely experienced the consequences when a shift handover note overlooks a crucial detail or a safety update fails to reach the night crew. Those small errors add up fast, costing businesses billions of dollars annually. This isn't just a local headache but a massive drain on resources that affects companies worldwide.

Many leaders still treat communication breakdowns as a cultural problem instead of a budget issue. The losses scatter: five minutes here, a reworked job order there, making them easy to miss on spreadsheets.

For non-desk industries, the impact cuts deeper. When crews rely on bulletin boards, word of mouth, or hurried shift briefings, a single missed message can idle a production line or strand a delivery truck at the wrong dock.

Limited digital access, rotating shifts, and dispersed sites turn every communication slip into a bigger problem. The real damage appears in four critical areas that impact every operation:

- Employee turnover from frustration and disconnection

- Lost productivity from unclear instructions and wasted time

- Compliance problems from missed policy updates

- Safety incidents from delayed or mistranslated alerts

Each of these areas quietly drains cash and morale, creating a chain reaction of delays, injuries, and waste that grows over time.

Calculate the True Cost of Missed Messages

Poor communication costs money in ways you don't always see coming. Missed instructions and tangled updates mean paying twice: once for the mistake and again to fix it. The damage appears in three main areas that hurt budgets hard.

1. Turnover

Turnover creates the biggest drain. When a forklift driver arrives to find the schedule changed without notice, frustration builds quickly. Information gaps drive 58% of employees to consider quitting. Every person who leaves triggers overtime costs to cover shifts, recruiting fees, and weeks of training before new hires reach full productivity. These expenses add up faster than most wage increases.

2. Lost Time

Lost time creates another major expense. Workers can spend hours each day hunting for clarity: re-reading instructions, confirming details, or tracking down missing information. These inefficiencies quickly add up to significant costs for any operation. Frontline teams feel this pain most because they frequently wait for shift briefings or radio updates just to get basic answers.

3. Compliance Failures

Compliance failures create the third major expense. Missed policy updates can trigger failed audits, while misplaced safety checklists lead to penalty territory. Non-desk environments face higher risks because information still travels by clipboard and bulletin boards. Every contested notice and re-inspection drains cash while damaging relationships with regulators and insurers.

Manufacturing and logistics operations feel these pressures most intensely because margins stay thin, so small mistakes create big problems. One misunderstood part number scraps an entire production run, and a late customs form holds thousands of dollars in product at ports. Clear communication protects profit faster than most other operational improvements.

Protect Your Team from Communication-Related Safety Risks

Clear, timely information sharing keeps workers safe. When messages arrive late or in the wrong language, accidents become almost inevitable.

This risk becomes especially serious for non-desk teams who face the highest dangers. A maintenance alert sits on a clipboard while a mechanic works under hazardous equipment. Weather warnings never reach the overnight crew unloading trucks. These workers depend on shift briefings and paper notices, so even small delays create serious hazards.

Language gaps make everything worse and contribute significantly to workplace accidents, highlighting that translation isn't optional on the shop floor. When a new hire can't understand instructions, they might mix chemicals incorrectly, skip safety procedures, or miss critical warning signs.

Information flow also determines whether workers report problems. Employees who feel unsafe speaking up face higher injury risks. When your forklift driver hesitates to report a blocked aisle because "it's probably nothing," the resulting collision affects everyone.

The costs extend far beyond medical bills: workers' compensation claims and legal fees drain budgets, regulatory investigations can shut down production for days, and team morale drops when workers question management's commitment to safety.

Consider an evening shift that never learns about a loose power cord spotted near the loading dock. One missed message leads to an injury, an investigation, and backed-up deliveries before morning. Poor information flow doesn't just inconvenience but threatens every person and process in your facility.

Stop Operational Problems Before They Multiply

Think about a single instruction that never reaches the night crew. The morning team arrives to find half-finished work, machinery standing idle, and a delivery window already blown. That lone misstep forces you to reshuffle schedules, pay overtime, and explain delays to frustrated customers.

The human cost follows quickly. Managers spend their day repeating instructions and fixing mix-ups. That constant re-teaching signals to crews that leadership is disorganized, creating frustration on both sides. Over time, trust breaks down. Teams begin to guard information, find their own work-arounds, or simply stop caring.

Customer experience suffers too: one missed shipment or botched service call can spark negative reviews that live online far longer than the original error.

Morale drops fastest among non-desk employees, who already feel removed from headquarters' updates. When they learn of new policies second-hand or discover safety changes only after an incident, they conclude their voices don't matter. Workers who feel disconnected work slower, share fewer improvement ideas, and leave sooner, multiplying your turnover costs.

These problems create a dangerous cycle that feeds on itself:

- Financial losses lead to safety shortcuts and reduced training

- Safety incidents damage team morale and increase regulatory scrutiny

- Low morale creates more information gaps and resistance to change

- Poor information flow generates more mistakes and wasted resources

Breaking this cycle starts with clear, timely updates that reach every worker before problems compound.

Build Clear Communication That Works

Effective workplace communication requires consistent channels and practices that everyone can rely on. Start by putting every update in one place. When you pick a single channel for shift changes, safety alerts, and policy news, people stop wondering where to look.

A posted board at the time clock, a text blast, or a short voice briefing at shift start all work as long as you use them consistently. Companies that let messages scatter across email, group chats, and word-of-mouth watch mistakes pile up and costs rise.

Language barriers create another layer of risk. Many workplace accidents involve language gaps, so translate critical notices, print visual signage, and keep an interpreter on call for emergencies. Simple steps like sending the same text in Spanish and English using AI reduce risk immediately. Multilingual teams need deliberate approaches that acknowledge diverse communication needs.

Automation eliminates human error in routine messaging. Since employees spend nearly two hours each day untangling unclear messages, a quick text that asks for a "Y" reply after reading a new safety rule closes that loop instantly. Automated prompts also keep certifications, equipment checks, and compliance tasks from falling through the cracks.

Two-way feedback builds trust and catches problems early. Workers who feel psychologically unsafe report more injuries, so invite questions at the end of every huddle, add a texting line for anonymous concerns, and thank people publicly when they spot a hazard. When crews see their input change real procedures, trust climbs and information gaps shrink.

You don't need to overhaul everything at once. Pick one channel, translate one key notice, automate one reminder, and open one feedback door. You'll notice the difference in fewer follow-up calls, smoother shifts, and safer workdays.

Turn Communication Into Your Competitive Advantage

Information gaps aren't just annoying: they're expensive and dangerous. Poor workplace communication costs companies $1.2 trillion each year because messages get lost, delayed, or misunderstood. If you lead HR or operations, that means every unclear update quietly drains your budget, safety record, and team morale.

You can start reversing the damage today. Standardize one clear channel for shift handovers, send updates in real time, and translate critical instructions so every employee knows exactly what to do regardless of language or device. When you remove guesswork, you reclaim wasted time, cut overtime, and keep crews safer.

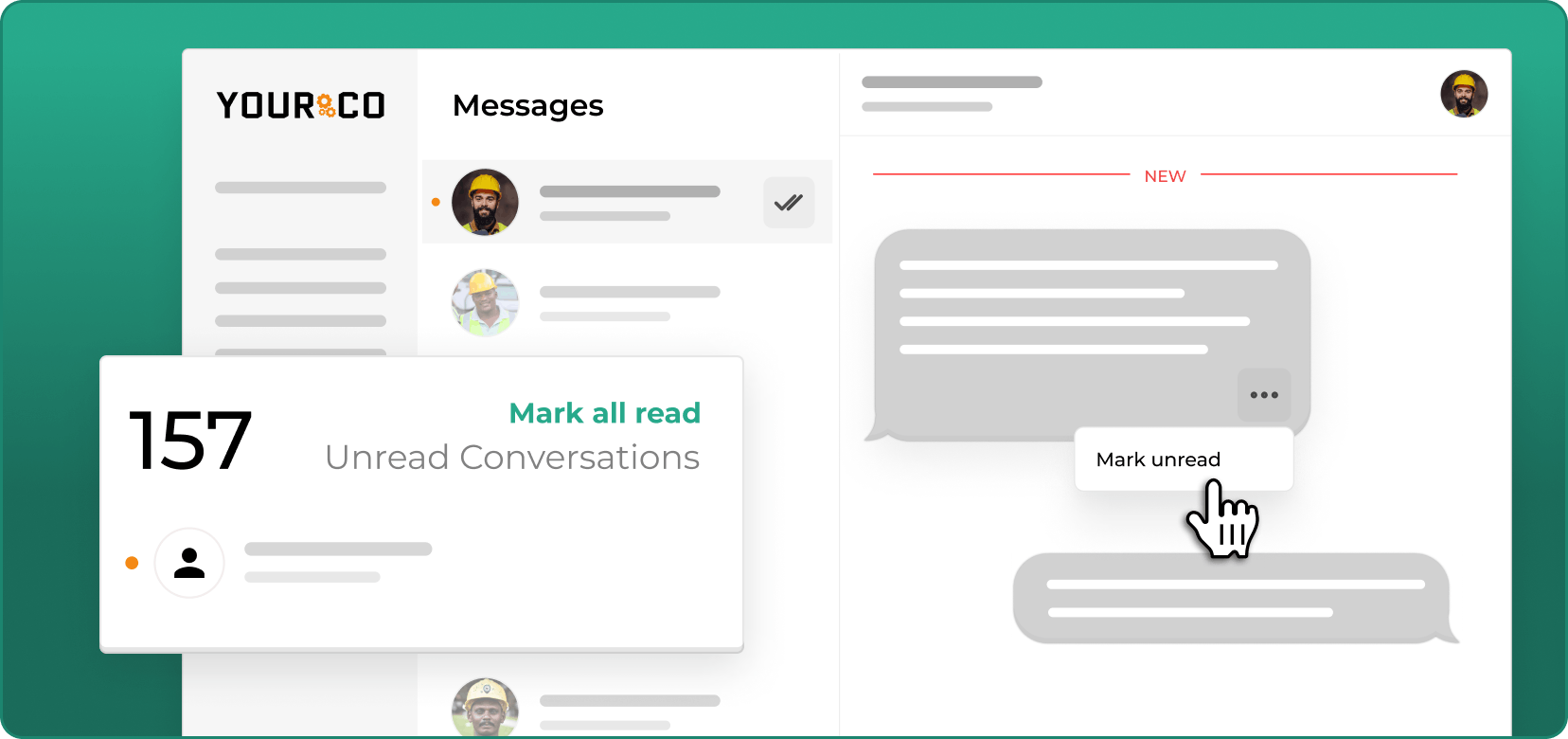

Yourco makes this transition simple by working on any phone without apps or internet required. With a 98% read rate, urgent alerts get seen, while real-time translation in 135+ languages and dialects closes information gaps across diverse teams.

Automated reminders and confirmations slash no-shows and errors, while timestamped logs provide instant proof during audits or investigations. Two-way texting lets workers ask questions and feel heard, building trust throughout your organization.

Ready to see the savings for yourself? Yourco keeps teams connected in seconds without extra hardware or training. Try Yourco for free today or schedule a demo and see the difference the right workplace communication solution can make in your company.

FAQs

What are the biggest drivers of miscommunication in industries with frontline workers?

Most frontline teams don't sit at computers, so updates move slowly through the ranks. Many workers depend on paper notices or quick shift briefings, which means they're often the last to hear about policy changes or safety alerts. Add in language differences and frequent shift handovers, and messages get lost or twisted along the way.

How can miscommunication directly affect employee turnover?

When people feel left out, frustration builds fast. That frustration turns into disengagement, then resignation. Since replacing a worker typically costs more than their annual wages, every preventable departure hurts your budget.

Why is miscommunication such a common cause of workplace accidents?

Safety instructions lose their power when they arrive late, get garbled, or come in the wrong language. Language barriers are a recognized workplace safety concern, and the problem gets worse when workers feel they can't speak up about hazards. Teams without psychological safety face higher injury risks because people won't report dangerous conditions. Mix rushed handovers with workers who stay quiet about dangers, and accidents become almost inevitable.

What communication practices are most effective for multilingual teams?

Keep messages simple, visual, and available in every language your team speaks. Many companies use short, clear texts paired with photos or icons, then provide translated reference materials. On-demand interpreters and real-time translation tools help during shift meetings or emergencies. Regular check-ins ensure workers understood the instructions, not just heard them. Two-way feedback matters just as much as good translation.

How can SMS-based communication improve both compliance and safety outcomes?

Text messages work on nearly every phone, so critical alerts reach people faster than emails or app notifications. You get timestamps showing when messages were delivered and can require quick responses, creating a clear record for compliance audits. Since texts arrive within seconds, you can send last-minute shift changes, safety warnings, or training reminders before small problems turn into big fines or injuries. Workers get a direct line back to management, making it easier to report hazards, send photos, and get help when they need it most.

How does reducing miscommunication translate into ROI for HR initiatives?

Clearer communication lowers turnover, cuts recruiting and training costs, reduces safety claims, and prevents fines from failed audits. It also boosts productivity because workers spend less time clarifying instructions. Over time, these savings compound, giving HR initiatives a more substantial financial and cultural impact across the workforce.