How to Build a Safety Feedback Loop and Training System That Scales Across Construction Sites

Keeping every crew member safe becomes far harder once your projects span multiple sites. Paper logs pile up in trailers, phone trees break down after hours, and minor hazards often go unreported until they turn into injuries. When workers hesitate to speak up about safety concerns — whether they fear blame, face language barriers, or simply can't find the right person to tell — small risks turn into serious accidents.

Construction sites face pressure to improve safety outcomes while managing crews across different locations and shifts. Workers need simple ways to report hazards instantly, while supervisors need reliable systems to track issues and deliver timely training. Traditional approaches often fail because they rely on complex processes that don't match the fast-paced, mobile nature of construction work.

You need a process that meets workers where they already are. The following sections show you how to set up that system, scale it across locations, and keep every team, regardless of language or device access, fully engaged in safety.

Start With Real-Time Safety Reporting

Traditional paper-based reports drift between clipboards and job trailers, leaving you with incomplete records and no way to compare what's happening across different sites. This scattered information hides dangerous patterns that could prevent future accidents.

Switching to real-time texting closes that gap. It gives every crew member a direct line to your safety team, no matter where they're working or what device they carry.

Set Up Your Company Safety Hotline

Smart setup starts with one dedicated phone number that acts as your company's "safety line." Post this number on every bulletin board, pay-stub envelope, and orientation packet so no one has to hunt for it when they spot a problem.

Keep the reporting format simple and memorable. Ask workers to text three basic things: what happened, where it happened, and whether anyone was hurt. A message like "near miss: loose railing level 3 east stair" gives you enough to take action..

Train your crew on this format during orientation. Practice with real examples so everyone knows exactly what to send when they're in the field. Simple formats work better than complex forms, especially when workers need to report something quickly while staying focused on the job at hand.

Encourage Photo Evidence and Quick Documentation

Pictures tell the story faster than words alone. Workers can snap a photo and send it along with their text, adding instant context that speeds up your response and helps with faster investigations.

Treat near-misses the same as actual incidents. A quick text about a tripping hazard today can prevent an injury tomorrow. SMS makes that notification possible even on remote sites with no internet connection.

Build automated replies that confirm receipt immediately. Workers need to know their message didn't disappear into a void. Since every basic mobile phone supports texting, SMS reaches your entire crew — no apps, no logins, no Wi-Fi dead zones.

Messages land within seconds and get read far more often than email. You also get a searchable, time-stamped record that exports easily for audits or insurance claims. Start small with a pilot program on your highest-risk site for one month, then refine your approach before rolling it out company-wide.

Centralize Feedback and Tag Safety Issues by Risk

Once reports start flowing in through your system, organizing them effectively becomes crucial. Construction teams often struggle with hunting through scattered paper logs and mismatched spreadsheets when trying to track safety trends.

Poor record-keeping hides important patterns across multiple crews. A single, cloud-based system solves this headache and helps you catch problems before they cause injuries.

Create Consistent Risk Categories Across All Sites

Route every SMS incident message into one central database — near-misses, photos, quick hazard notes, everything. Create a simple set of tags that covers most field situations: fall hazards, equipment failures, PPE problems, and environmental conditions.

When Site A uses the same categories as Site B, your safety data stays consistent and comparable. This consistency lets you spot trends that might be invisible when each location tracks things differently.

Assign a risk level to every report using a simple system: critical, high, medium, low. This basic triage helps supervisors tackle dangerous issues first while keeping track of smaller concerns. After collecting data for a few months, you can generate heat-maps showing which sites have recurring ladder problems or ongoing PPE compliance issues.

Set Up Role-Based Safety Dashboards

Different people need different views of your safety data. Site supervisors need to see open items and upcoming deadlines for their specific location. Regional managers want to compare injury trends across multiple projects to identify training needs.

When everyone gets the information they need in a format they can actually use, problems get fixed faster. Your whole organization learns from each incident instead of letting valuable lessons get buried in paperwork.

Custom dashboard views also help with accountability. Supervisors can see which reports are still open and track their team's progress on safety improvements. This transparency keeps safety issues from falling through the cracks during busy periods.

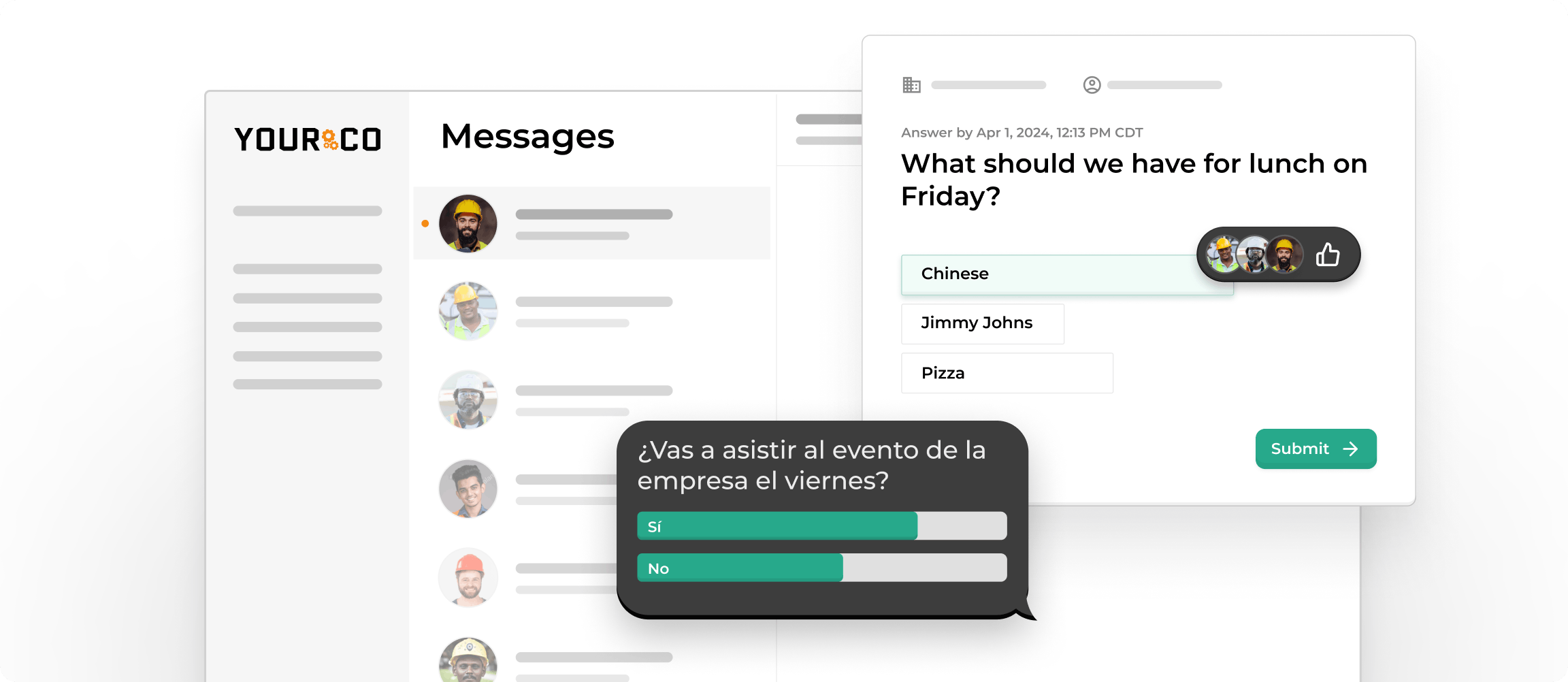

Send SMS-Based Safety Surveys That Actually Get Read

Beyond incident reporting, getting feedback before problems happen helps identify potential hazards early. Quick, focused text surveys reach your crew where they already pay attention.

SMS messages have a 98 percent open rate compared to email's 20 percent. This means your safety feedback actually makes it back to you rather than getting buried in cluttered inboxes.

Design Short, Actionable Survey Questions

Keep each survey short and focused. One or two straightforward questions work well within the 160-character limit and prevent confusion across language barriers.

For multilingual teams, modern texting platforms support multiple languages and work on basic phones. This ensures you don't exclude workers who don't have smartphones or reliable data plans.

Sample questions that generate actionable feedback include:

- "Did you spot any new hazards during today's walk-through? Reply Y or N."

- "Rate today's toolbox talk clarity from 1 (confusing) to 5 (crystal-clear)."

- "Which PPE item needs restocking most: gloves, hard hats, or safety glasses? Reply G, H, or S."

- "How safe did you feel working at height today? Reply with a number 1-5."

Time Your Surveys for Maximum Response

Timing makes all the difference in response rates. Schedule surveys for predictable moments when crews expect communication: ten minutes before the morning safety meeting, right after lunch break, or just before shift end.

When you tie the message to existing routines, workers develop an easy habit. They see the text, respond quickly, and move on with their day. If you manage multiple sites, stagger delivery times so each location gets personalized attention while all responses flow into your central dashboard.

Start with one well-timed question every Friday for a month and track response rates. Once crews get comfortable with the routine, add a second question or rotate topics weekly. This gradual approach prevents survey fatigue while creating steady data flow.

Deliver Safety Training and SOPs Directly to Phones

Effective communication extends beyond collecting feedback — it also involves delivering critical safety information when and where workers need it most. Getting every crew member on the same page is hard when each jobsite has its own hazards, languages, and deadlines.

Text-based training cuts through that chaos. It puts short, clear lessons in every worker's pocket, even when there's no internet connection available.

Break Complex Topics Into Bite-Sized Modules

Breaking complex topics like fall protection, heat stress, and PPE fit into two-to-three-minute modules improves retention. When lessons stay short and focused, workers actually absorb the information instead of getting overwhelmed.

Text a secure link to each module so workers can tap once, watch a clip, and mark it done. If reception is weak, an offline PDF still delivers the key points without requiring a data connection.

Spacing content over several days improves memory and lets supervisors check that skills are applied on site. The system automatically tracks confirmations with time-stamped receipts that satisfy OSHA record-keeping and simplify audits. Mandatory training compliance becomes much easier when every interaction is automatically documented.

Build a Living Library of Safety Procedures

Create a searchable library of SOPs for confined-space entry, ladder setup, emergency weather plans, and other critical procedures. Tag each file by hazard level so when a new risk pops up, you can text the right module immediately.

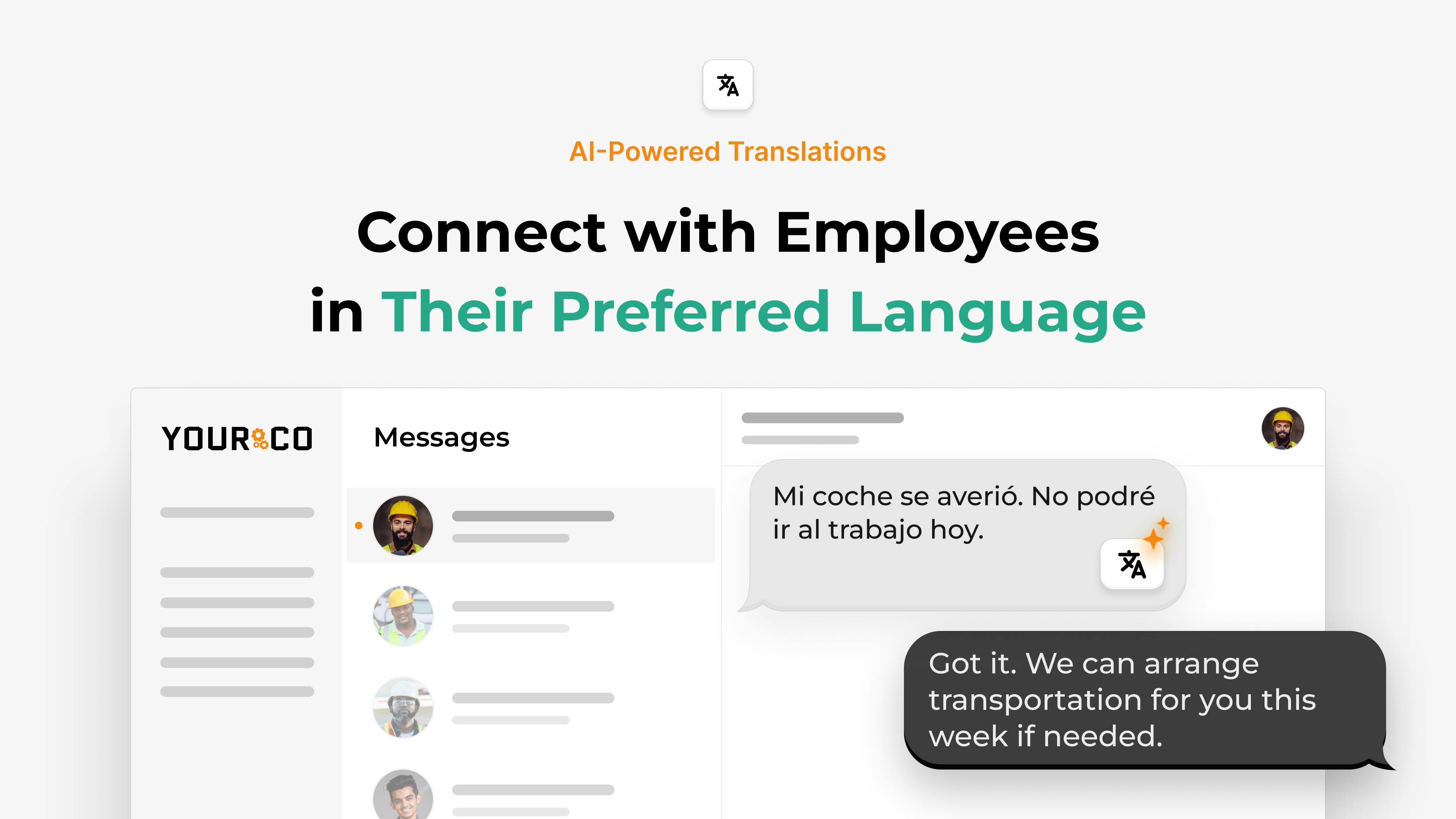

This beats scheduling another classroom session when conditions change quickly. AI tools can push Spanish, Tagalog, or Marshallese versions within seconds, mirroring multilingual programs used on diverse sites.

Workers get instant access to the exact procedure they need, right when they need it. Supervisors don't have to track down printed copies or wonder if everyone has the latest version.

Close the Loop With Follow-Up Actions

The most advanced reporting system fails if workers don't see results from their input. When workers share a hazard, they expect to see something change.

If nothing happens, or no one tells them what did, they stop speaking up. You keep participation high by responding quickly, tracking progress, and showing the results.

Respond Immediately to Build Trust

Set up an automatic acknowledgment that triggers the moment a text comes in. Your system should confirm receipt with something like "Got it—thanks for flagging the loose guardrail. We'll update you soon."

This instant reply shows workers their message didn't disappear into a filing cabinet. It builds confidence that someone is actually paying attention to their safety concerns.

Assign the issue a risk level and owner right away. Since all reports flow into one dashboard, you can tag it "critical" and route it to the site supervisor immediately. While the fix is underway, send status checks so the reporter and everyone on that crew knows where things stand.

Share What Changed and Why It Matters

Once the hazard is resolved, share what changed, why it matters, and how it prevents repeat accidents. Short texts work best: "Update: Guardrail fixed and inspected. No fall risk. Thanks for speaking up—your report kept everyone safe today."

To make these messages effortless, build response templates for the most common issues — PPE shortages, equipment failures, housekeeping hazards. Templates save time and keep your tone consistent, even when different managers send the updates.

Aim for a clear timeline: immediate acknowledgment, 24-hour status update, and final confirmation when resolved. Recognize participation with monthly shout-outs or small rewards for crews with the most near-miss reports. When every report triggers a quick, transparent follow-up, your safety feedback system stays alive and workers keep talking.

Track and Improve Safety Participation Over Time

Measuring the effectiveness of your SMS-based safety system requires tracking the right metrics consistently. Start by monitoring the numbers that show whether your safety system is actually working.

Focus on training completion rates, near-miss reports, and injury trends. These three metrics tell you everything you need to know about safety engagement.

Monitor the Metrics That Matter Most

Training completion tells you right away if workers are engaged. When completion rates drop, you know workers are either too busy or the content isn't connecting.

Near-miss reporting matters just as much as injury rates. When reports increase after launching SMS surveys, it means crews feel safe speaking up. This is a strong predictor that serious accidents will drop.

Don't ignore actual injury rates either. Keep tracking Total Recordable Incident Rate and DART. Companies that consistently beat industry averages combine quick training with fast follow-up on every hazard report.

Use Data to Drive Targeted Improvements

When numbers move in the wrong direction, check your SMS logs for patterns. Maybe one site struggles with fall protection or one shift ignores PPE reminders. The data will show you exactly where to focus your efforts.

Set up regular reviews that fit your team's schedule. Weekly dashboards work well for site supervisors, while regional leaders benefit from quarterly deep dives. During each review, pick one improvement goal — boost survey response by ten points or cut resolution time in half — and assign someone to own it.

Small, focused targets prevent overwhelm and keep your safety program moving forward. When you see clear progress on specific metrics, it's easier to justify the investment and get buy-in for expanding the program.

Strengthen Safety Culture With Yourco's Scalable System

Building a strong safety culture requires fast feedback, clear action, and training that reaches everyone. Text messages arrive instantly and work without internet, so field teams report hazards the moment they spot them, even on remote sites.

Every report goes into one dashboard, helping you identify patterns across all sites instead of tracking down paper forms or checking multiple apps. This centralized approach reveals trends that would be invisible when each location manages safety data separately.

Yourco keeps the process moving with real-time feedback collection that confirms receipt of each report and shows next steps. Multilingual training links sent by text help crews review safety lessons in their preferred language. Cross-site tracking reveals important patterns like near-miss reports and training completion rates.

Instant follow-up messages show workers their input drives real changes, which builds the trust necessary for strong safety culture. This all works without app downloads, passwords, or Wi-Fi requirements, ensuring every worker can participate, even those using basic flip phones or working in areas with limited connectivity.

The platform integrates with over 240 HRIS and payroll systems, automatically syncing employee data so your safety communications reach the right people at the right time. AI-powered translations support over 135 languages, eliminating language barriers that often prevent non-English speakers from participating in safety programs.

Ready to see how straightforward safety culture can be? Try Yourco for free today or schedule a quick demo and see what real-time, text-based engagement looks like on your sites.

Frequently Asked Questions

How does SMS-based safety reporting work for crews with limited English?

Yourco's AI-powered translation supports over 135 languages and dialects, so workers can report hazards in their preferred language while management receives translated summaries.

Can workers without smartphones participate in the safety feedback system?

Yes, SMS works on any cell phone, including flip phones. Workers don't need internet access, apps, or passwords to report safety concerns or receive training updates.

How quickly do safety reports reach supervisors through text messaging?

Safety reports arrive within seconds via SMS, allowing supervisors to respond immediately to critical hazards instead of waiting for paper forms or email checks.

What happens if a safety report gets lost or ignored?

Every SMS safety report is automatically logged and timestamped in Yourco's dashboard, creating a searchable record for compliance and ensuring no report disappears.