Craft Your Perfect SOP Template

Get Ready to Transform Your Operations with Battle-Tested SOP Templates

SOPs provide tremendous value in any industry. Whether you manage construction teams, manufacturing crews, warehouse staff, or field service technicians, SOPs ensure consistency across shifts, locations, and skill levels while reducing training time and improving safety compliance. When your team works across multiple sites or different shifts, standardized procedures serve as your operational backbone.

In fact, organizations with well-structured SOPs see impressive results. Manufacturing companies report 25% reductions in production cycle time and 20% decreases in defects when they standardize processes, while businesses using effective SOP systems experience 35% increases in employee productivity and 25% fewer operational errors.

This guide delivers both immediate value and long-term strategy. You'll find quick-start templates to implement today, plus detailed instructions for building comprehensive SOP systems that grow with your organization. From defining purpose to maintaining documents that evolve with your business, we'll show you how to create SOPs using an SOP template that your team will actually use.

Download Your Free SOP Templates Now (10+ Formats Included)

Skip the guesswork and start creating professional SOPs right away with our collection of ready-to-use templates. These fully editable SOP templates solve the most common SOP problems: poor accessibility, unclear instructions, and inconsistent formatting. Each template includes proven best practices from successful organizations across manufacturing, construction, and logistics industries. Mobile-optimized versions ensure your frontline workers can access critical procedures from any device, anywhere on the job.

Choose Your Format:

Standard Operating Procedure Template by Microsoft Word

Company SOP Template by Microsoft Word

Standard SOP Template by Google Docs

Simple SOP Template in Google Docs

Medical Technician SOP template

Each SOP template includes pre-formatted sections for purpose, scope, responsibilities, and step-by-step procedures. Customize them to match your specific processes, terminology, and organizational structure. The following sections provide detailed guidance on maximizing their effectiveness for your operation.

How to Build Your SOP Template in 6 Steps

The following sections provide detailed guidance for each step in the SOP creation process. These steps directly address common implementation challenges like poor accessibility, overly complex writing, and low employee adoption rates. By following this systematic approach, you'll create SOPs that employees actually use, not documents that collect dust. Whether you're managing a small team or a large enterprise across multiple locations, these steps adapt to fit your organizational size, industry requirements, and operational complexity.

1. Define Purpose & Scope of Your SOP Template

Clear purpose and scope definition directly addresses the complexity and poor writing challenges that cause many SOPs to fail. Start by answering these essential questions: What specific process are you documenting? Why does this process need standardization? Where does the procedure begin and end? What situations trigger its use? What measurable outcomes indicate successful completion?

Keep your scope tightly focused. A well-defined SOP covers one complete process, not multiple related tasks. For example, in manufacturing, create separate SOPs for "Equipment Startup Procedure" and "Daily Equipment Maintenance Checklist" rather than combining them into an unwieldy "Equipment Operations Manual."

Write a clear purpose statement like: "This SOP ensures consistent quality control testing of incoming materials to prevent defective products from entering production." This focused approach makes your SOPs easier to follow, update, and train on—directly improving the adoption rates that many organizations struggle with.

2. How to Get the Right People Involved in Your SOP Template Creation

SOPs fail when the people who actually do the work aren't part of creating them. Low adoption rates happen because employees reject procedures they had no voice in developing.

Build your stakeholder team with these key roles:

- Process owners who understand business requirements and the bigger picture

- Daily users who know practical realities and common obstacles

- Compliance personnel who ensure regulatory requirements are met

- Trainers who will teach procedures to new employees

Collect input through direct observation of current processes, structured interviews with experienced workers, and surveys to capture pain points. For non-desk workers in manufacturing, construction, or logistics, conduct on-site interviews during actual work shifts. This reveals real-world constraints like equipment limitations or safety protocols that desk-based planners often miss.

Track feedback in a simple spreadsheet with columns for stakeholder role, input received, and how it was incorporated. A warehouse team's input about forklift maintenance procedures revealed that the original SOP missed critical safety checks. After incorporating their feedback, equipment incidents dropped by 40%. Their hands-on experience caught what the initial draft missed entirely.

3. Collect the Right Information Before You Write Your SOP Template

Incomplete SOPs create more problems than no SOPs at all. Missing information is one of the biggest barriers to successful implementation. Teams waste time guessing at procedures, making mistakes, and constantly asking for clarification. Thorough preparation prevents these headaches entirely.

Build your resource collection around these core materials:

- Current procedures from both official documents and employee knowledge

- Regulatory requirements for your industry and location

- Equipment manuals and technical specifications

- Safety data sheets and hazard documentation

- Screenshots of software interfaces and system processes

- Digital tool links and platform access information

Manufacturing teams need machine specs, quality standards, and maintenance schedules. Construction operations require safety protocols, material specifications, and compliance requirements. Logistics teams should gather shipping regulations, tracking system documentation, and warehouse procedures.

Create digital folders organized by category to keep everything accessible during drafting. Label folders clearly and store screenshots with descriptive filenames. This systematic approach means you won't pause mid-writing to hunt for missing information.

Thorough information gathering cuts revision cycles in half and eliminates the confusion that kills SOP adoption. Your future self will thank you when training sessions run smoothly and employees actually follow the procedures you create.

4. How to Pick the Perfect SOP Template Format for Your Team

Your format choice determines whether employees actually use your SOPs or ignore them completely. You have four primary options, each designed for different operational needs and complexity levels.

Simple step-by-step format works best for straightforward, linear processes with clear sequential actions. Manufacturing tasks and basic administrative procedures thrive with this direct approach that takes employees from start to finish without confusion.

Hierarchical steps format becomes essential for procedures with more than ten steps or multiple sub-processes. This approach uses numbered main steps with lettered sub-steps, breaking down complex procedures into digestible chunks that prevent overwhelm.

Flowchart format proves invaluable for decision-heavy processes where employees must evaluate conditions and choose different paths. Quality control procedures, troubleshooting guides, and approval workflows benefit significantly from this visual approach that maps out every possible scenario.

Checklist format works perfectly for verification processes, safety protocols, or any situation requiring confirmation that employees complete multiple items. Think pre-flight checks or equipment inspections where missing a step creates serious problems.

For non-desk workers, prioritize mobile-friendly formats with clear visual elements and minimal text density. Visual aids and flowcharts significantly improve comprehension and reduce errors, particularly in fast-paced operational environments where employees need quick, clear guidance. Implementing these via unified communication systems ensures consistency and accessibility across your organization.

We'll explore each format in greater detail in the upcoming section on template selection.

5. How to Write Clear, Actionable SOP Steps

Your SOP needs these core sections to function effectively:

- Title and ID number for easy identification and tracking

- Purpose statement explaining why this procedure exists

- Scope defining what's covered and what isn't

- Responsibilities clearly assigning roles using job titles rather than names

- Definitions for technical terms

- Equipment and materials needed

- Numbered procedure steps as sequential actions

- Quality control checkpoints

- References to related documents

- Approval signatures with revision history

Write each step as a single action using active voice. "Inspect the equipment" works better than "Equipment should be inspected." Manufacturing procedures need specific tolerances and measurements. Construction SOPs require safety checkpoints at critical stages. Logistics operations must specify timing requirements and deadlines.

Focus on essential actions while eliminating unnecessary detail. Your frontline workers need clarity, not complexity. Include visual aids like diagrams or photos for equipment operation, safety procedures, or any step where seeing beats reading.

Skip industry jargon entirely. The person following your SOP might be new, stressed, or working in challenging conditions. Simple language prevents costly mistakes and speeds up task completion.

6. How to Test and Train Your SOP for Maximum Adoption

Testing and training determine whether your SOP becomes a valuable operational tool or joins the graveyard of ignored procedures. Poor training and support cause more SOP failures than bad writing, making this step critical for long-term success.

Run pilot tests with actual users who will follow your draft SOP step-by-step. Station observers during these sessions to document hesitation points, repeated questions, and moments where people deviate from written instructions. These gaps reveal clarity issues that subject matter experts miss when reviewing documents alone. Focus especially on steps that seem obvious to experienced workers but confuse newcomers.

Design training that addresses different learning styles and skill levels. Multi-format training programs significantly boost SOP adoption rates compared to single-method approaches. Combine written reference materials with visual aids for complex processes and hands-on practice for critical procedures. For non-desk workers accessing SOPs on mobile devices, including training on navigating procedures in their actual work environment is essential. Our SOP training for non-desk staff provides strategies to ensure effective communication and training.

Track training effectiveness through attendance records, competency assessments, or practical demonstrations. This documentation proves proper training during audits and identifies knowledge gaps before they cause problems. Pair new employees with experienced mentors during their first few SOP implementations to bridge the gap between training and real-world application.

Secure final approvals from designated stakeholders once testing shows no major issues and training materials are complete. Distribute finalized SOPs through accessible channels that match how employees actually work. Whether through company intranets, SMS alerts, or physical posting stations, accessibility determines whether people can find procedures when they need them most.

How to Customize SOP Templates for Your Industry

Manufacturing, construction, and field-based industries each face unique operational challenges that require tailored SOP approaches. Your industry's regulatory environment, safety requirements, and workforce characteristics directly shape how procedures should be structured and implemented.

Manufacturing

Manufacturing SOPs work best when they integrate lean manufacturing principles and focus on eliminating waste while maintaining quality control. Essential procedures include equipment startup/shutdown protocols, quality assurance checklists, and safety procedures for hazardous materials. Utilizing effective SOPs for manufacturing can lead to significant improvements in production efficiency and quality.

Visual step-by-step guides with embedded checklists deliver the strongest results, especially when offered in multiple languages for diverse workforces. One mid-sized manufacturer that redesigned its SOPs using lean principles and employee input achieved a 25% reduction in production cycle time and 20% reduction in defects.

Free Downloadable Manufacturing SOP Template

Construction & Field Operations

Construction SOPs put safety first, covering site-specific equipment inspection, hazardous material handling, and emergency response procedures. Developing comprehensive safety operating procedures helps maintain safe workplaces, especially for non-desk workers. Since workers access these procedures on tablets and smartphones in the field, mobile-friendly formats are non-negotiable.

Flowcharts excel for decision-heavy processes like permit verification or safety incident reporting. Color-coded sections help workers instantly identify critical safety steps versus routine procedures, reducing errors when time pressure is high. Utilizing safety alert templates can help in creating clear communication for emergencies.

Free Downloadable Construction SOP Template

Warehousing & Logistics

High-volume warehouse operations demand checklist-style SOPs that workers can reference quickly during inventory management, shipping procedures, and equipment operation. Speed and accuracy matter equally.

QR codes linking physical locations to digital procedures ensure workers always access current information without slowing operations. Integration with warehouse management systems creates seamless workflows that maintain both speed and compliance. Implementing efficient work order systems alongside your SOPs can further enhance operational workflows.

Free Downloadable Warehousing SOP Template

Agriculture

Agricultural SOPs must accommodate seasonal variations in equipment maintenance, crop handling, and food safety compliance. These procedures need to adapt throughout growing cycles while maintaining regulatory compliance.

Mobile optimization becomes critical since agricultural workers operate across vast areas with no desktop access. Visual formats with minimal text work best, accommodating the diverse literacy levels common in agricultural workforces.

How to Build SOPs That Your Team Actually Uses

Don't let your SOPs gather digital dust. Implement these proven strategies to transform procedures into operational tools that drive real results, not compliance paperwork your employees ignore.

Write for Real People, Not Compliance Officers

Your team will use SOPs when they understand them instantly. Keep language simple and sentences direct, especially for teams where English isn't everyone's first language. Avoid technical jargon unless absolutely necessary. When you must use specialized terms, define them clearly right there in the document. Emphasizing good employee communication ensures alignment and effective implementation.

Make Access Effortless

Teams ignore SOPs buried in complex file systems, regardless of how well you write them. Store procedures in centralized, cloud-based platforms with effective search functions. For teams working outside the office, optimize everything for smartphone viewing with offline access capabilities. Effective communication for non-desk workers is essential in fast-paced environments. Your warehouse workers and field technicians need answers when they're on the job, not when they return to a desk.

Co-Create with Your Frontline Team

Frontline workers who use processes daily create the best SOPs. Include both managers and frontline staff through interviews, direct observation, and structured feedback sessions. This collaborative approach directly tackles the biggest SOP killer: procedures that look perfect on paper but fail in real-world conditions. Engaging employees in this way, and providing clear guidelines, can act as non-monetary benefits for engagement.

Use Visuals That Actually Help

Flowcharts, diagrams, and images clarify complex procedures faster than walls of text. This works especially well in manufacturing, construction, and logistics where workers need quick reference guides. Color-code different step types: safety warnings in red, quality checks in blue, decision points in yellow. Utilizing safety alert templates can help in creating clear communication for emergencies. This helps users navigate efficiently under pressure.

Design for Smartphones First

Non-desk workers consider mobile access essential, not just convenient. Create SOPs that display clearly on phone screens with large fonts and minimal scrolling. Add QR codes linking equipment directly to relevant procedures so staff can avoid searching through document libraries when time matters most.

Maintain Consistency Across Multiple Locations

Multi-site operations require procedures that remain consistent while allowing necessary local variations. Create core procedures that work everywhere, with clearly marked sections for local regulations, equipment differences, or cultural considerations. Implement version control systems to ensure all locations receive updates simultaneously, preventing dangerous inconsistencies.

One mid-sized manufacturer reduced training time by 40% and cut quality issues by 30% within six months after implementing visual, mobile-optimized SOPs developed with extensive frontline input.

Set Review Cycles That Stick

Create regular review schedules based on your industry's pace: quarterly for fast-moving sectors like technology, annually for stable operations. Treat these reviews as non-negotiable calendar appointments with clear ownership assigned for each SOP's maintenance. This prevents procedures from becoming outdated documents that employees learn to ignore, keeping them as valuable operational tools that grow with your business.

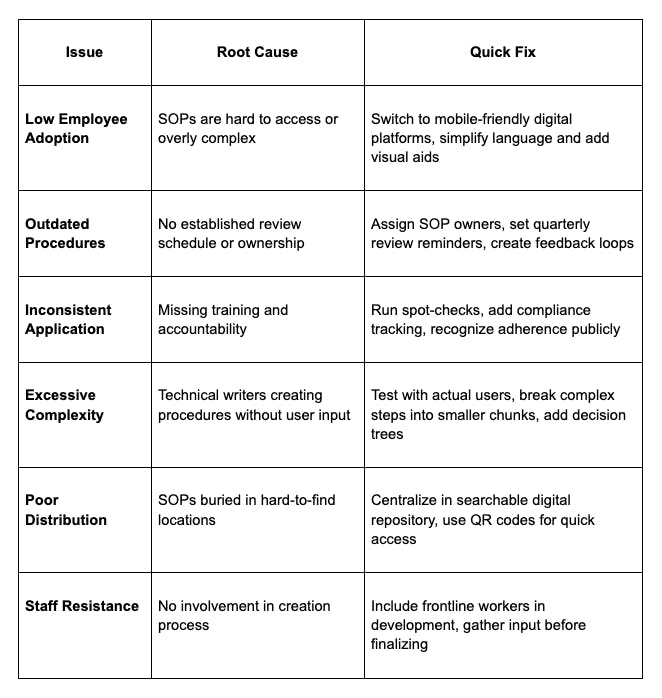

Spot the Red Flags: Your SOP Troubleshooting Guide

Well-intentioned SOP initiatives can stumble. Rather than viewing these challenges as roadblocks, treat them as diagnostic signals that guide you toward stronger operational foundations. Use this troubleshooting guide for the most common SOP implementation issues:

Field teams need SOPs that work in real conditions. Focus on mobile-friendly formats that load quickly on smartphones, since most non-desk employees find complex apps or desktop platforms uncomfortable to use. Visual instructions consistently outperform text-heavy formats. Create offline-accessible versions for areas with spotty connectivity, and consider voice-guided procedures when workers need their hands free.

Watch for frequent "exception" requests, declining quality metrics, and new employee confusion during training. When conflicting priorities consistently override documented procedures, your team has lost respect for your SOPs. Staff creating unofficial "workarounds" clearly signals that your procedures don't match reality.

Every challenge provides feedback in disguise. Use these signals to continuously improve your SOP system and create procedures that truly support your team's success.

How to Keep Your SOPs Current and Effective

Your SOPs aren't "set it and forget it" documents. They function as living systems that must evolve with your organization. Insufficient maintenance ranks among the top reasons SOPs become ineffective, transforming once-valuable procedures into outdated paperwork that employees ignore. Without regular updates, even the best-written SOP becomes a liability rather than an asset.

Establish regular review cycles based on how often your processes change. High-change environments like technology or regulatory compliance need quarterly reviews, while stable manufacturing processes might require only annual updates. The key is consistency. Mark your calendar and stick to the schedule, treating SOP maintenance as seriously as any other operational requirement.

Several triggers should prompt immediate SOP updates: process changes, new technology implementations, regulatory updates, recurring errors, or consistent employee feedback about confusing steps. Create feedback mechanisms that make it easy for frontline workers to suggest improvements. They often spot outdated or problematic procedures first. A simple suggestion box or regular check-ins can catch issues before they become widespread problems.

Implement version control best practices by numbering updates sequentially and maintaining a revision history that tracks what changed, when, and why. For detailed guidance on ensuring compliance, refer to our SOP compliance guide.

When communicating updates, don't rely solely on email. Use multiple channels to ensure the message reaches distributed teams, especially non-desk workers who might not check email regularly.

For organizations with mobile workforces, SMS notifications work better than traditional communication methods since every smartphone can receive text messages. Pair these alerts with mobile-friendly update summaries that highlight critical changes. An updated SOP that nobody knows about creates the same problems as an outdated one.

Your SOP Questions Answered

Q: How long should an SOP be?

A: Focus on clarity over word count. Keep procedures concise while including all necessary details. Complex procedures with more than ten steps work better with a hierarchical format that breaks down tasks into digestible chunks.

Q: Should I include images and videos in my SOPs?

A: Absolutely. Visual elements boost comprehension and adoption rates significantly. Incorporate flowcharts, diagrams, and screenshots when they clarify complex steps or decision points. This proves especially valuable for non-desk workers who rely on visual guidance to complete tasks correctly.

Q: What's the difference between policies and procedures?

A: Policies define what should be done and why, while procedures explain how to do it step-by-step. SOPs function as procedures that provide specific instructions for completing tasks consistently across your organization.

Q: How do I handle exceptions to standard procedures?

A: Build appropriate flexibility into your SOPs by creating decision trees for handling exceptions. Distinguish between mandatory steps and flexible guidelines. Document common exceptions and their approved alternatives so employees know when and how to deviate safely.

Q: How can I measure SOP effectiveness?

A: Track compliance rates, training time reduction, error frequency, and employee feedback. Modern SOP systems provide analytics that monitor adherence and identify improvement opportunities. Look for patterns in where employees struggle or skip steps.

Q: What's the best way to transition from paper to digital SOPs for field workers?

A: Start with mobile-optimized formats and provide offline access capabilities. Your digital platform must work on various devices and in areas with poor connectivity. Consider QR codes that link equipment directly to relevant procedures, making information instantly accessible when needed.

Transform Your Operations with Smart SOP Templates

Start with any SOP template that matches your immediate need. Organizations using structured SOPs cut training time while boosting both compliance and productivity. Your operational foundation starts with your first download. Grab what you need and begin building the consistency that drives real results.

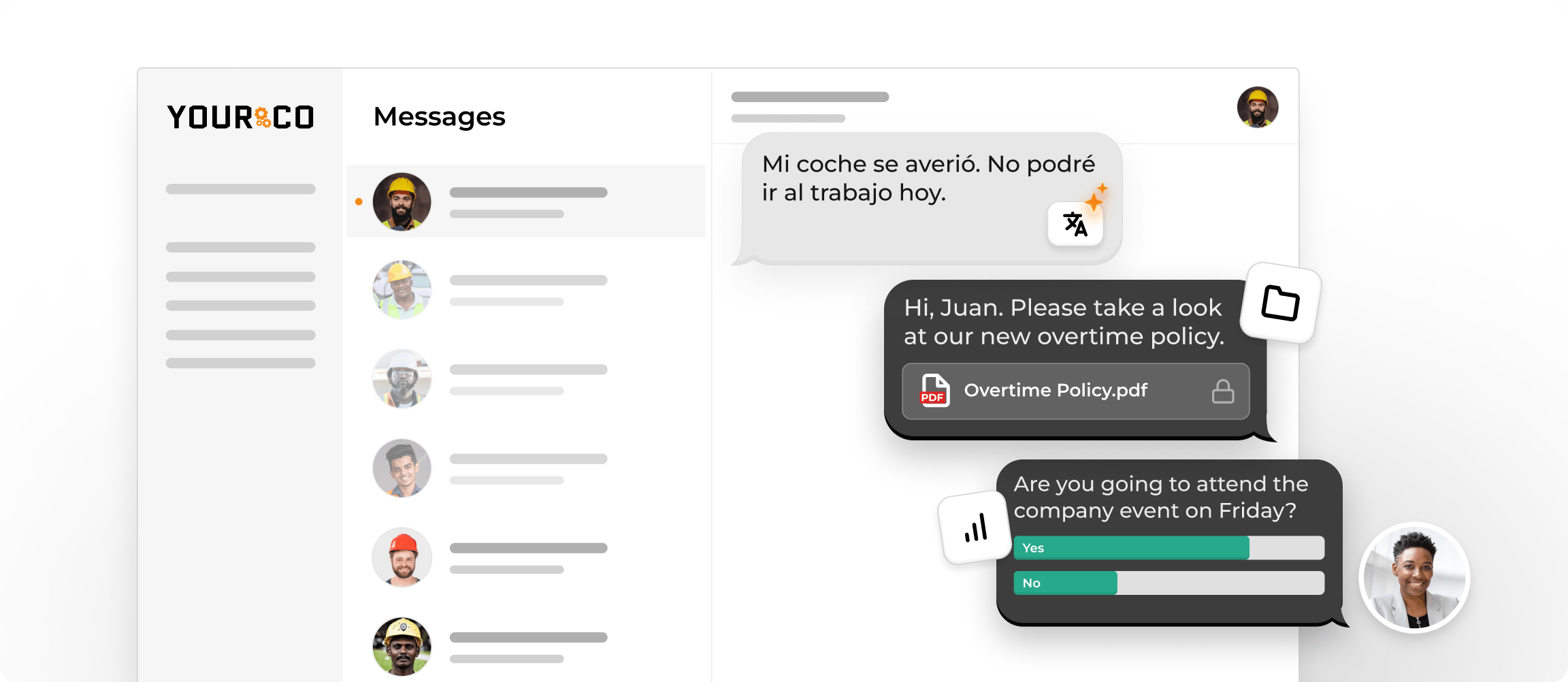

As you implement your SOPs, leverage the power of Yourco's SMS solution to ensure that your team stays informed, engaged, and compliant. SMS is ideal for non-desk workers, who often lack access to email or mobile apps. It guarantees that your updates are delivered instantly and securely to every employee, ensuring that important information reaches them wherever they are. The ability to send quick updates, confirm receipt of key information, and gather instant feedback means you’re not only adopting the right processes but continuously improving them.

Yourco also provides secure document access, allowing you to send critical documents to your team via SMS, with built-in protections like passwordless authentication and encrypted file transfers. This ensures that sensitive information stays secure while being delivered without delay. Additionally, Yourco’s two-way communication capabilities foster active engagement, allowing your team to ask questions, clarify doubts, and respond directly, making it easier to maintain alignment and ensure compliance.

With Yourco, you don’t just implement SOPs, you transform your operations into a well-oiled machine, backed by structured consistency, real-time feedback, secure document access, and seamless communication. Take the first step today and watch your organization thrive.

Try Yourco for free today or schedule a demo and see the difference the right workplace communication solution can make in your company.