Boost Maintenance Efficiency With an SMS-Powered Work Order System for Every Team

When equipment breaks down, every minute counts. Yet many maintenance teams still rely on phone calls, spreadsheets, and memory to coordinate repairs across multiple locations. The result? Communication breakdowns, missed deadlines, and frustrated technicians who spend more time tracking down information than fixing problems. These coordination challenges multiply when your workforce operates across different sites, shifts, and skill levels, with many team members having limited access to traditional communication tools like email or desktop systems.

Modern work order systems solve these coordination challenges with mobile-friendly, SMS-enabled platforms designed for hands-on teams. In this guide, you'll discover how the right system drives measurable improvements in productivity, cost control, and accountability across your entire maintenance operation.

Boost Productivity With Modern Work Order Systems

Organizations that implement streamlined work order systems typically see immediate improvements across their operations. These improvements become even more pronounced when managing large facilities or teams that spend most of their time away from traditional office setups.

Cut Wasted Time Through Better Coordination

A centralized system eliminates the duplicate work that happens when multiple people tackle the same issue without knowing it. Smart scheduling ensures technicians arrive at job sites with the right parts and tools, while automated routing cuts travel time by directing staff to the nearest priority task.

Digital access to equipment manuals, maintenance histories, and step-by-step instructions means fewer delays waiting for information. Most organizations find that reducing paperwork alone saves 3-5 hours per technician each week, time that gets reinvested into actual repairs and preventive maintenance.

When repairs happen faster, you create a positive cycle where fewer emergency breakdowns mean more capacity for the preventive work that keeps systems running smoothly.

Reduce Costs Across Labor and Materials

Effective work order tracking drives measurable cost savings in several key areas:

- Lower repair costs: Preventive maintenance reduces emergency repairs by 60–70%, since planned work is far cheaper than reactive fixes.

- Smarter inventory spending: Accurate tracking avoids both rush orders and wasted stock.

- Reduced labor costs: More efficient schedules cut down on overtime.

- Energy savings: Well-maintained equipment runs more efficiently and consumes less power.

- Lower insurance premiums: Strong maintenance records show reduced risk to insurers.

- Compounding value: Proactive maintenance creates year-over-year savings across all areas.

Improve Task Coordination and Priority Management

Standardized workflows ensure requests get handled consistently and nothing goes unnoticed. Instead of random "hallway requests" that disrupt planned work, all maintenance needs flow through clear channels with proper prioritization.

This structure gives managers real-time visibility into workload distribution and helps them adjust assignments based on changing priorities or team availability. Teams report higher job satisfaction when they have clear priorities instead of constantly shifting between urgent "emergencies."

The transparency also creates natural accountability. When everyone can see task status and completion timelines, it becomes easier to recognize strong performers and identify bottlenecks early.

Minimize Errors and Miscommunication

Digital systems significantly reduce the human error that comes with manual tracking and verbal instructions. Templates ensure critical information never gets missed, while standardized procedures reduce miscommunication.

Automatic time tracking eliminates the guesswork that typically happens at shift end. For regulated industries like healthcare, manufacturing, and energy, this accuracy translates directly into compliance benefits and legal protection during audits.

Build Stronger Accountability Through Transparency

Modern work order systems create clear visibility into who's working on what, when tasks are due, and what's still pending. This transparency naturally encourages responsibility without creating a micromanagement environment.

Time-stamped task tracking makes it easy to identify delays and recognize high performers. Managers can review real-time dashboards instead of hunting down status updates. Requesters can track their submissions without interrupting busy technicians.

This clarity supports objective performance discussions and creates a defensible record that protects your organization during inspections or disputes.

Choose the Right Features for Maximum Impact

The most effective work order systems go beyond simple task logging. Look for these capabilities that directly improve how maintenance work gets done:

Consistent Workflows and Templates

When every work order follows the same format, technicians know exactly what information they'll receive and how to respond. This consistency reduces confusion and improves repair quality.

Built-in templates guide users to include all necessary details, reducing incomplete requests that cause delays. Custom templates for different maintenance types give you flexibility while maintaining quality standards.

Mobile-First Design

Field staff can't wait to get back to a desk to update their progress. Mobile access allows real-time status updates, photo documentation, and immediate access to repair histories—all while still on-site.

Look for systems that work fully on smartphones and tablets, with offline capabilities for areas with poor connectivity. GPS integration helps dispatch the closest available technician and improves emergency response times.

Real-Time Tracking and Smart Notifications

Automatic status updates keep teams aligned without constant phone calls. Customizable notifications ensure the right people get updates without overwhelming anyone with unnecessary alerts.

Managers gain dashboard visibility for smarter resource planning, while requesters can check progress independently. Different notification settings for different roles ensure everyone gets relevant information when they need it.

Complete Information Capture

Strong systems make it easy to provide technicians with everything they need for successful job completion. Photo and video attachments help diagnose issues before arrival, sometimes enabling remote solutions.

Historical repair data automatically links to equipment records, giving technicians context about recurring problems. Input validation flags missing information before submission, preventing incomplete work orders.

Assignment and Scheduling Optimization

Effective systems don't just track work—they help ensure the right person handles the right job at the right time. Smart workload balancing prevents any technician from being overwhelmed while others have capacity.

For complex repairs, the system ensures proper sequencing and triggers notifications when prerequisite work is complete.

Implement Your Work Order System Successfully

Getting maximum value requires thoughtful planning and execution:

1. Start With a Thorough Needs Assessment

Begin by mapping your current maintenance workflows with input from technicians, managers, and frequent requesters. Identify the biggest pain points, such as:

- Communication delays

- Missing parts

- Unclear priorities

- Inadequate documentation

Consider your technical environment and workforce characteristics. Will you need offline access? Multi-language support? Integration with existing systems? These requirements should drive your platform selection.

2. Select the Right Platform for Your Team

Use your needs assessment to define must-have features. For organizations with field teams, mobile accessibility should be non-negotiable.

SMS capability becomes especially valuable when managing non-desk workers— all mobile device owners can receive text messages, making it the most universal communication channel available.

Evaluate integration options with your current tools, particularly HRIS or inventory management systems. When systems share data automatically, you avoid duplicate entry and gain better operational visibility.

Plan for growth. Choose a system that can scale with additional locations, equipment, or workforce expansion.

3. Plan Your Rollout Strategy

Develop standardized procedures for request submission, approval workflows, and task tracking. Define clear categories, priority levels, and escalation paths.

Plan a phased implementation rather than launching everything at once. Set success metrics like adoption rates, completion times, and error reduction to track your progress and identify needed adjustments.

4. Prepare Integration and Data Migration

Before full deployment, test how your new system connects with existing platforms. Verify API connections, user permissions, and authentication methods to prevent launch delays.

Clean up historical data before migration. Decide what maintenance records and equipment histories need preservation, and remove duplicate or incomplete entries.

Test integration with inventory and procurement systems to ensure parts ordering and stock updates happen automatically.

5. Design Training for Different Roles

Create role-specific training focused on what each group needs to succeed—technicians, supervisors, requesters, and administrators. Use hands-on demonstrations and provide quick reference guides for common tasks.

Implement strong change management practices. Show teams how the new system simplifies their work and provides clearer communication. Address concerns quickly and highlight specific benefits for each role.

6. Launch With Continuous Monitoring

Start with a pilot in one department or location. Use this controlled environment to identify issues and optimize workflows before wider rollout.

Collect feedback through surveys, direct observation, and system analytics. Monitor adoption rates, task completion accuracy, and user satisfaction to guide improvements.

Once confident in your setup, expand to other areas using lessons learned from the pilot. Maintain regular communication, celebrate early wins, and continue refining based on user feedback.

Simplify Implementation With SMS-Based Solutions Like Yourco

Traditional work order systems often create implementation challenges—from complex training requirements to device compatibility issues and employee resistance. For teams working across multiple locations or in field environments, SMS offers a remarkably simple alternative that eliminates most common barriers.

Yourco, an SMS-based employee platform, transforms how organizations coordinate maintenance work by meeting teams exactly where they are: their messaging inbox. Instead of requiring app downloads or new interfaces, technicians receive assignments, provide updates, and submit completion photos through familiar text messaging.

Eliminate Training Barriers

Unlike complex work order platforms that require extensive onboarding, SMS-based systems leverage technology your entire team already understands. Everyone knows how to send and receive text messages, removing the learning curve that typically slows adoption.

Yourco requires no software installation, password management, or navigation training. Workers simply respond to text messages using their existing messaging app, making the transition nearly invisible.

Reach Every Team Member

Traditional implementation often struggles with device compatibility and network limitations. Yourco's SMS platform works on any mobile phone—smartphones and basic phones alike—ensuring complete workforce coverage regardless of device type.

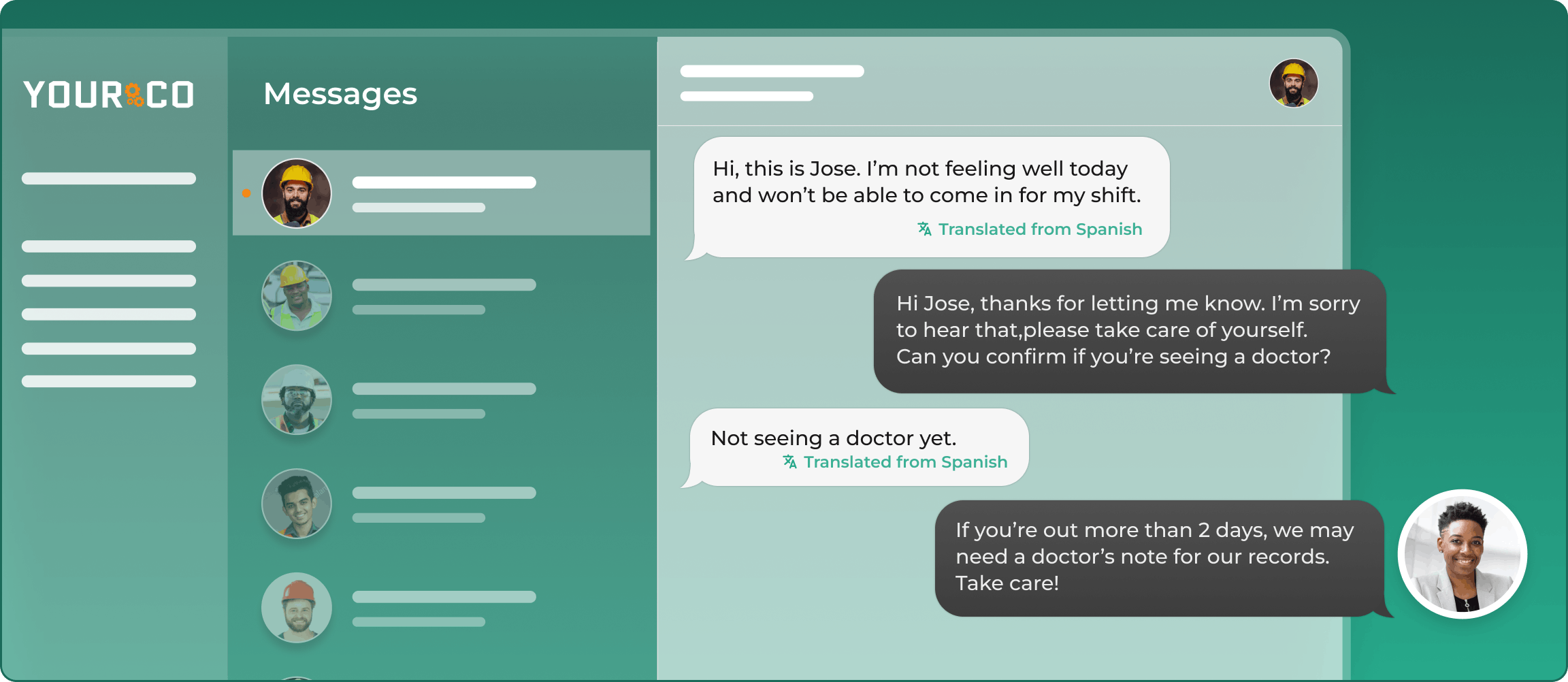

Yourco's AI-powered translation feature automatically delivers work orders in each employee's preferred language from over 135 options available. This removes language barriers that often complicate maintenance coordination, ensuring every assignment and safety instruction is fully understood.

The platform uses toll-free numbers, so employees never pay messaging charges, eliminating financial barriers and ensuring high participation rates across your entire team.

Deploy Rapidly Without IT Complications

SMS-based systems dramatically reduce implementation timelines. While traditional work order platforms often take months to deploy fully, Yourco can be operational within days.

The setup requires minimal IT involvement, reducing strain on technical resources and avoiding complex infrastructure changes. Organizations can quickly establish workflows, create message templates, and connect with existing HRIS systems through straightforward integrations.

Scale Across Multiple Locations

Whether you're managing one facility or coordinating hundreds of teams across regions, Yourco provides the flexibility to scale without creating operational bottlenecks. Each location can operate with customized messaging while maintaining company-wide standards.

Local managers can send site-specific work orders, schedule updates, or urgent maintenance alerts tailored to their teams. Corporate leadership maintains the ability to distribute standardized procedures or safety communications across the entire organization.

Customizable access controls allow different management levels to oversee only their relevant departments while maintaining appropriate visibility. This prevents information overload and ensures employees receive instructions from trusted local supervisors.

Generate Actionable Insights

Beyond communication, Yourco captures engagement and response data that reveals operational patterns. Real-time dashboards show how quickly work orders get acknowledged, which types of maintenance requests are most common, and where follow-up communications might be falling short.

These insights enable continuous improvement of your work order process—refining message templates, adjusting scheduling practices, and rebalancing workloads based on data rather than assumptions.

The platform automatically logs all maintenance communications with timestamps, creating a comprehensive audit trail for compliance purposes and dispute resolution.

Streamline Absence Reporting and Schedule Adjustments

Yourco's "text off line" feature allows maintenance staff to quickly notify supervisors when they can't make scheduled shifts or assignments by simply texting the company number. This creates clear, written documentation while automatically alerting relevant managers to make schedule adjustments.

The system works with any phone type, ensuring even technicians with basic mobile devices can report absences. Every message is timestamped and logged, creating a searchable record for compliance tracking and workforce planning.

Send Updates and Company Announcements

Important maintenance policy updates, safety reminders, and procedural changes can be distributed instantly to your entire team or segmented by location, shift, or role. This ensures critical information reaches everyone who needs it, regardless of email access.

The platform enables two-way communication, allowing technicians to ask clarifying questions about work orders or report completion status directly through text. All communications are archived for audit purposes and future reference.

Use Advanced Workforce Analytics for Maintenance Teams

Yourco tracks attendance patterns, message responsiveness, and communication effectiveness across your maintenance workforce. This frontline intelligence helps managers identify performance trends, spot potential staffing issues, and optimize work assignment distribution.

Centralized dashboards provide visibility into which technicians consistently respond to work orders, attendance patterns by location, and overall team engagement levels. These insights support data-driven decisions about training, scheduling, and resource allocation.

Streamline Your Operations Starting Today

Coordinating maintenance takes more than tracking tasks—it requires real-time communication and tools that work in the field. SMS-based systems like Yourco make it simple to connect every team member, reduce delays, and capture critical updates instantly.

By turning routine text messaging into a powerful coordination tool, Yourco helps you eliminate missed requests, improve repair times, and give leaders full visibility across locations.

Ready to boost efficiency and simplify maintenance operations? Try Yourco for free today or schedule a demo and see the difference the right workplace communication solution can make in your company.

Frequently Asked Questions

How long does it typically take to implement a work order system?

Implementation timelines vary significantly based on system complexity and organizational size. Traditional platforms often require 3-6 months for full deployment, while SMS-based solutions like Yourco can be operational within days due to their simplicity and universal accessibility.

How do SMS-based work order systems handle complex maintenance procedures?

SMS platforms excel at coordination and status updates while linking to detailed procedures stored in connected systems. Technicians receive assignments and provide updates via text, but can access comprehensive repair guides, equipment manuals, and safety protocols through secure links shared in messages.

What about employees who don't want to use their personal phones for work?

Quality SMS-based systems like Yourco use toll-free numbers for key functions such as absence reporting, ensuring no personal cost to employees for those messages. The communication flows through existing messaging apps rather than requiring dedicated work applications, maintaining clear boundaries between personal and professional use.

Can work order systems integrate with existing maintenance management software?

Most modern platforms offer robust integration capabilities with HRIS, inventory management, and CMMS systems. SMS-based solutions often provide simpler integration processes since they focus primarily on communication rather than replacing entire maintenance workflows.