Guide to Implementing Microlearning in Manufacturing

Training programs that pull entire teams away from their work for hours create operational headaches and productivity losses across every industry. Traditional classroom-style sessions disrupt workflows, require scheduling coordination, and often fail to stick when workers return to their actual tasks.

The most effective learning happens in small, focused bursts that workers can apply immediately rather than comprehensive courses that try to cover everything at once. This targeted approach addresses the reality that most employees need quick refreshers on specific tasks rather than lengthy theoretical instruction.

Microlearning is an approach that delivers bite-sized training modules in three to seven minutes, each focusing on a single critical task like checking clamp pressure or executing lockout procedures. These short, focused lessons fit seamlessly into natural breaks during shifts, giving operators exactly what they need without stepping away from their workstation.

What Microlearning Looks Like on the Factory Floor

Microlearning on the production line means focused lessons you can complete in the time it takes a machine to cycle. Each piece runs three to seven minutes and tackles one specific task. You might scan a QR code on a press, or open a text message with the link and launch a quick clip showing the exact torque sequence you need, then apply it immediately and get back to production without missing a beat.

This approach completely flips the traditional training model. Instead of pulling entire crews into conference rooms for hour-long presentations, workers access targeted content only when they need it, right at their station. The narrow scope and just-in-time timing keep production moving while making updates painless.

Content Structure and Formats

Manufacturing teams structure their content libraries around immediate, actionable tasks. For example:

- A 3-minute lesson: Cover verifying clamp pressure on a specific mold before the cycle starts

- A 4-minute safety refresher: Demonstrate lockout-tagout steps for individual machines

- A 5-minute module: Walk through recognizing the top five defects on a particular product line

Formats stay practical and accessible. Short, captioned videos work well in noisy production areas. Two-question quizzes pop up on handheld scanners or tablets. Single-screen job aids display annotated photos of exact procedures. Flashcards help workers memorize fault codes, while one-minute text updates push last-second specification changes directly to phones.

Regardless of format, the rule remains constant: one clear objective, delivered quickly, so workers can act on it immediately.

Why Manufacturers Are Turning to Microlearning

Production schedules demand training that builds skills without shutting down the line. Short lessons delivered in 3–7-minute bursts fit neatly into prep time, break windows, or changeovers instead of requiring dedicated classroom hours.

Shift work creates additional training complexities. Since micro-modules work on phones, tablets, or kiosks, they reach every crew regardless of when they clock in. Content translates easily, and captions or visual cues help multilingual teams maintain consistent standards across all shifts.

Manufacturing processes evolve rapidly, and training must keep pace. Updating a three-minute video takes minutes rather than the weeks required to rewrite comprehensive courses. This rapid adaptation capability ensures training stays current when specifications shift or new equipment arrives.

How to Identify Training Needs for Microlearning

Start by pinpointing tasks where a short, focused refresher would prevent errors, speed up changeovers, or enhance safety. An honest audit of current training gaps will reveal exactly where microlearning delivers the biggest impact.

Begin by walking the production floor with supervisors, noting where mistakes, rework, or near-misses occur most frequently. You can also use SMS surveys to gather insights directly from your employees. Combine these observations with incident logs and quality data to create a comprehensive picture. While three-minute modules won't fix fundamentally broken processes, they excel at reinforcing critical steps that operators forget when lines run at full capacity.

Ideal Topics for Microlearning

During your assessment, look for subjects that naturally break into single objectives:

- Safety procedures: PPE checks, lockout/tagout sequences, and hazard identification

- Equipment operations: Startup, shutdown, and changeover procedures

- Quality control: Defect recognition and inspection protocols

- Standardized work: 5S reminders and consistency maintenance across shifts

- Basic maintenance: Lubrication schedules, simple troubleshooting, and calibration procedures

Each potential topic should pass a straightforward evaluation:

- Is the procedure high-risk or error-prone?

- Does it happen frequently enough that variation creeps in across shifts?

- Does new equipment or process changes create knowledge gaps?

- Are safety or compliance refreshers required between formal certification cycles?

Score each task against these criteria and rank by potential impact. High-risk, high-frequency procedures rise to the top priority, while lower-impact items can wait.

Deliver Training Through Multiple Channels

Effective delivery meets workers where they already are — on the shop floor, often seeking quick information during brief breaks. When every minute away from production matters, the simplest access path wins.

Text Messaging for Instant Access

Text messaging excels at connecting with non-desk workers because it reaches any phone without requiring employees to download special software or learn new systems. A well-timed text can remind technicians to watch a 90-second video before changeover or prompt a quick quiz during break. Keep messages concise and link to content that loads quickly on any device. This approach respects the reality of noisy, glove-wearing environments while still tracking completion.

QR Codes and Station Access

Pair text messaging with QR codes placed directly on equipment that open the exact lesson for that machine or task. A quick scan of a strategically placed sticker can launch a three-minute startup checklist or visual job aid — no searching required, just instant help precisely where needed.

For areas where personal devices aren't permitted, position tablets at key stations. These can access content on demand while supervisors track usage through existing training systems. Since microlearning content files are small, they download quickly and can be stored offline in areas with unreliable connectivity.

This multi-channel approach covers all scenarios: text reminders point to QR-triggered lessons, station tablets record completion, and training systems aggregate the data for analysis.

Create Content Workers Will Use

Design each lesson to be immediately actionable so workers can apply it the moment they return to their stations. When modules take only three to seven minutes, teams can complete them quickly, absorb key points, and resume work without falling behind production targets.

Focus and Visual Design

Focus on one clear objective per module. Instead of attempting to cover an entire assembly procedure, create a targeted clip titled "Verify torque on fastener series X." This focused approach aligns with proven microlearning principles that demonstrate optimal retention in short, concentrated bursts.

Prioritize visual content creation. A quick video filmed on real production equipment beats slide presentations every time. Workers in noisy manufacturing environments rely heavily on captions and clear visual cues, so add step-by-step annotations and design large, glove-friendly interface buttons for touchscreen interactions.

Real-World Usage and Language

Design for real-world usage patterns. QR codes on equipment, barcodes at workstations, or NFC tags on tool chests should open exactly the lesson workers need, not a homepage requiring navigation. This direct access helps operators who rarely have spare minutes and may work in areas with inconsistent connectivity.

During content creation, maintain simple language and incorporate real examples from actual defect reports. After each demonstration, include a quick summary slide highlighting common mistakes to prevent recurring errors. These details make lessons feel relevant and demonstrate respect for workers' time constraints.

Version Control

Establish robust version control procedures. Process specifications change frequently, and revised torque settings or updated safety requirements should trigger fresh three-minute videos rather than comprehensive course overhauls. Swapping updated micro-content maintains accuracy without creating additional downtime, proving more effective than rebuilding entire training programs.

Make Microlearning Instant With Text Messaging

Text messaging transforms microlearning into an immediate resource that reaches every worker within seconds. Since virtually every operator carries a mobile phone, short text messages arrive faster than any kiosk notification or classroom announcement. These messages integrate naturally into pre-shift huddles, break periods, or transitions between work stations.

Message Strategy and Timing

Craft each message around one focused point. Individual texts should cover single concepts, then link to brief resources or request quick responses. Lead with clear benefits ("Avoid scrap on Line 2") and close with simple actions like "Reply Y to confirm." Ensure all links function well on mobile devices and load rapidly, even with limited plant connectivity.

Strategic message sequences build consistent learning habits. Consider a 6 a.m. safety reminder: "Remember the five lockout points on Press 8. Watch this 45-second overview before clocking in." A mid-shift quiz reinforces the key steps. End-of-day reports show completion rates and comprehension scores.

Automation and Scheduling

Automated scheduling maintains consistent delivery. Program two to four messages per week, timed to shift beginnings and natural break periods. Implement spaced repetition to reinforce critical content over time. Opt-in subscription lists respect privacy concerns, while multilingual message templates serve diverse workforces effectively.

Since text messaging requires no downloads, passwords, or special training, it provides workers with instant, repeatable coaching exactly when needed. This transforms microlearning from "another training requirement" into a practical production support tool that adds real value to daily operations.

Ensure Worker Engagement and Adoption

Effective microlearning adoption starts with solving genuine problems that frustrate workers daily. Identify recurring challenges like persistent defect pattern or a safety procedure that slows production, then deliver a focused three-minute lesson that helps resolve it on the next shift. When workers see measurable improvements like reduced scrap rates or faster setup times, they actively seek out additional training opportunities.

Leadership and Motivation

Engage floor supervisors early in the rollout process. These leaders already coach workers throughout each shift, and their endorsement signals that quick training modules matter as much as meeting production targets. Supervisors also identify when lessons miss the mark, providing immediate feedback for rapid improvements. Since microlearning modules are brief, implementing corrections is straightforward and cost-effective.

Implement simple motivation strategies. Public recognition on communication boards, friendly competitions between crews, or team rewards when groups complete assigned modules work effectively. Because individual modules require only minutes to complete, these incentives feel achievable and fair for all participants.

Accessibility and Feedback

Prioritize accessibility over elaborate reward systems. QR codes on machinery, text links before breaks, and videos under seven minutes ensure workers never need to leave the production floor. Visual content with captions cuts through factory noise while supporting teams speaking different languages.

Common barriers include tight schedules, varying technology comfort levels, language differences, and general training skepticism. Address these challenges by collecting feedback after each module. Simple "Was this helpful?" surveys and follow-up conversations with team leaders help identify problems quickly. When workers see rapid improvements based on their input, trust builds and participation increases naturally.

Deliver Training to Every Worker With One Text

Microlearning enables skill development without production interruption. Short, targeted modules integrate seamlessly into natural downtime, reducing classroom hours while increasing floor time. Each lesson's brief duration allows pilot programs to launch more quickly, with easy updates or replacements when specifications change.

Text messaging provides the fastest path to reach every operator, and allows you to connect with workers who rarely check email, require no specialized applications, and accommodate any shift pattern. Include links to 90-second demonstration videos or brief quizzes, delivering training precisely when needed most. Unlike apps that create barriers for non-desk workers through data limitations and download reluctance, text messaging eliminates these issues with an approach that requires no downloads, no internet, and no passwords.

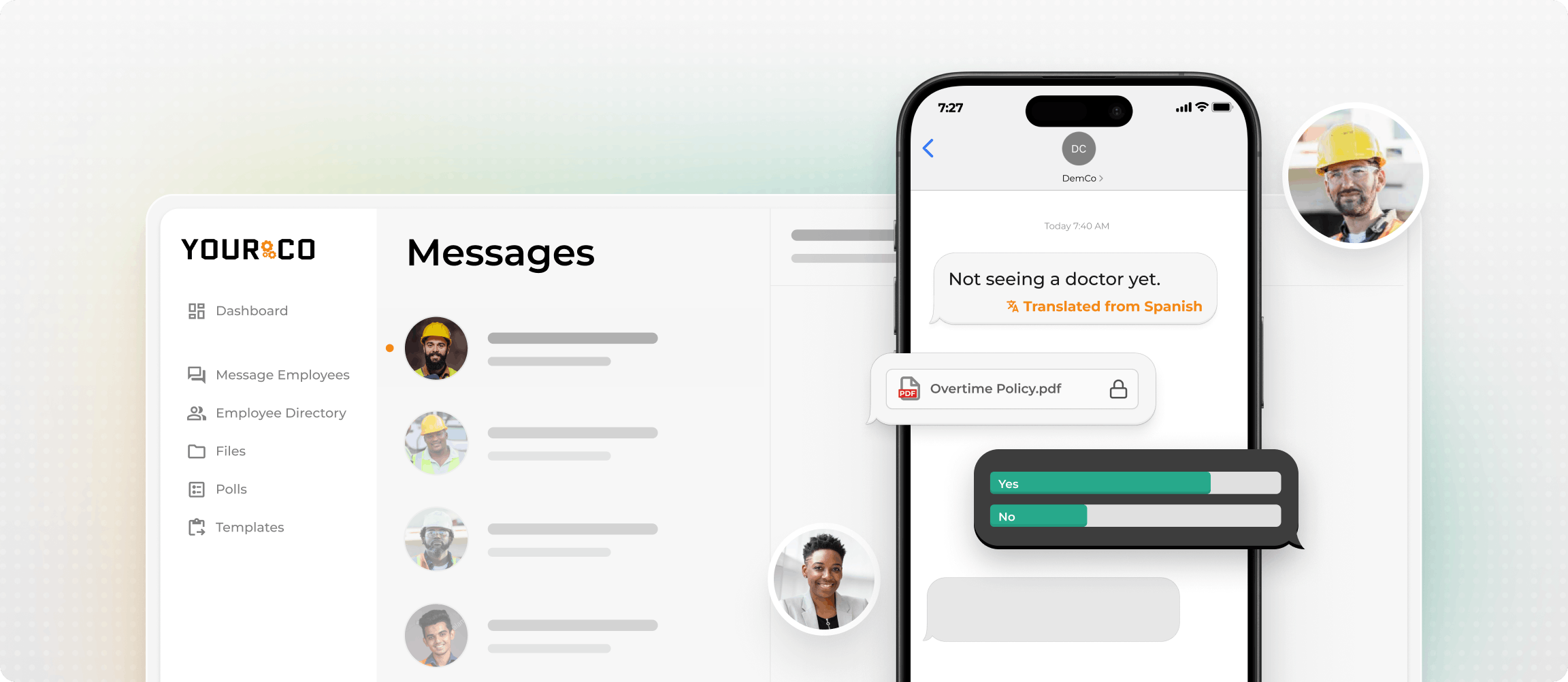

Yourco simplifies the entire process further. Send micro-lessons directly to employee phones, confirm completion automatically, and gather feedback — all through one intuitive dashboard. No downloads, no group messaging confusion, just clear communication that maintains production momentum.

With AI-powered translations supporting over 135 languages, every worker receives training in their preferred language. Built-in polls and surveys collect real-time feedback to strengthen engagement and reduce turnover, while secure document access enables employees to access the resources they need to increase productivity and grow.

Try Yourco for free today or schedule a demo and see how easy it is to deliver training without slowing production.

Frequently Asked Questions

What types of manufacturing training work best with microlearning?

Start with short, repeatable tasks that are safety-critical. Think lockout/tagout steps, quick defect checks, changeover sequences, and PPE refreshers. These bite-sized lessons let workers grab exactly what they need right when they need it, cutting errors and downtime.

How long should a manufacturing microlearning module be?

Keep them between 3–7 minutes. That's long enough to cover one clear task, yet short enough to finish during a break or while equipment warms up. You can stretch to 10 minutes if you need richer video content, but shorter usually works better.

Can microlearning replace hands-on training completely?

No, and you wouldn't want it to. Use microlearning to prep workers before they start and refresh their memory afterward. You still need supervised practice for complex setups or certifications, but a quick 4-minute refresher right before the task helps cement key steps and builds confidence.

How do I ensure workers complete the microlearning modules?

Make it relevant and keep it simple. Send lessons right when workers need them, make navigation straightforward, and include a quick quiz so they see immediate value. When content directly helps with their daily tasks, completion rates improve significantly.

What's the best way to deliver microlearning to shift workers?

Text messaging works exceptionally well. Text messages reach every phone without needing downloads, and workers consistently read them. You can include links to short videos or quick reference cards, timed perfectly for pre-shift huddles or breaks.

How do I measure ROI for microlearning in our plant?

Connect each module to a specific plant metric, like scrap rates, changeover time, or near-miss incidents. Track completion rates, quiz scores, and watch how those metrics change over 30–60 days. Plants using this approach see faster procedure updates and measurable drops in errors.