How to Build a Lean Manufacturing Culture Across Multiple Sites

Managing lean transformation across multiple manufacturing sites creates a unique challenge: how do you maintain consistency while respecting local differences? When your Atlanta plant runs three shifts, your Phoenix facility handles different product lines, and your newest location in Ohio is still ramping up, a one-size-fits-all approach falls apart quickly.

We know how challenging this sounds when you're already coordinating between sites, managing different union agreements, and ensuring corporate standards don't stifle local innovation. That's exactly why this guide focuses on six practical phases that take you from aligning leadership across locations to sharing wins company-wide. Each phase includes specific multi-site considerations, coordination templates, and ways to track progress so you can turn good intentions into measurable results across every facility.

Here's what you can expect: synchronized improvements that work at each location, faster knowledge transfer between sites, better coordination between facilities, and local teams who contribute solutions that benefit the entire organization. Most importantly, you'll build a system that keeps improving at every location even when corporate attention shifts to other priorities.

Phase 1: Set Clear Direction from Leadership Across All Sites

Real change needs clear direction from the top, but multi-location operations require both corporate vision and local ownership. When your leadership team agrees on one main goal that works across different facilities — your "north star" — everyone can see how their site's daily work drives bigger company wins.

Start by creating a simple charter that connects corporate profit goals to metrics each location can actually control, like production time or quality rates. The key difference for multi-site operations: set corporate targets that roll down to location-specific goals based on each site's capacity, equipment, and market demands.

Set up monthly corporate reviews where site leaders check progress, remove cross-location roadblocks, and adjust targets based on what's actually happening across all floors. But also schedule quarterly visits where corporate leadership spends time at each facility, not just reviewing numbers but walking the floor and talking directly with frontline teams.

Write your main vision in terms anyone can understand, then share it everywhere: daily team updates, employee surveys, even paycheck inserts. Keep repeating it until every employee at every location can explain how their work connects to the bigger picture. Send quick pulse surveys every month asking, "Can you explain how your work connects to our main goal?" to check if the message is getting through across all shifts and sites.

Multi-Location Leadership Structure

Every successful multi-site improvement effort needs both corporate guidance and local ownership. Here's the structure that works:

Corporate Level:

- Operations Director who can allocate resources between sites immediately

- Corporate Lean Champion to ensure consistent methods across locations

- HR Business Partner to align training and recognition company-wide

- Finance Partner to translate improvements into consolidated impact

Site Level:

- Plant Manager with authority to implement changes locally

- Local Lean Lead trained in corporate standards but empowered to adapt

- Shift Supervisors who understand both local needs and corporate expectations

Weekly Corporate Calls (30 minutes):

- Review key metrics from each location

- Identify cross-site priorities and resource needs

- Address issues that affect multiple facilities

- Share quick wins and schedule knowledge transfers

Monthly Site Visits (Half-day):

- Corporate leaders visit different locations on rotation

- Direct floor conversations with frontline teams

- Remove obstacles that require corporate intervention

- Recognize location-specific achievements publicly

If you're managing sites in different time zones, record key messages and send them via text so all locations receive the same information simultaneously, even when live meetings aren't practical.

Phase 2: Standardize Your Waste Assessment Across Sites

Most multi-site organizations know they're losing time and money, but comparing performance fairly between locations requires identical assessment methods. Your Memphis facility might excel at changeovers while Denver struggles with inventory flow, but you won't know without standardized waste mapping.

Create identical waste assessment templates that work across all your locations. Schedule synchronized mapping sessions during the same week so corporate can compare results fairly. Gather cross-functional teams at each site: operators, maintenance staff, quality inspectors, and local finance support.

Pick the same process type at each location — like setup procedures or quality checks — and walk through every single step together using your standard template. This lets you spot which sites should mentor others and where corporate investment will have the biggest impact.

While you map each step at every location, collect the same data points:

- How long each task actually takes

- Time spent switching between different products

- How much inventory sits between steps

- Defect rates and rework time

- Crew sizes and coverage gaps

For sites that don't have exact data, use the same estimation methods and mark what needs verification. Consistency in measurement matters more than perfect accuracy when you're comparing multiple facilities.

Once you've gathered this performance data across locations, AI-powered analytics can help identify patterns and optimization opportunities that might not be obvious through manual analysis alone. Advanced data analysis tools excel at spotting correlations between different waste types and operational variables across multiple sites.

Watch for these seven common waste patterns that appear differently across locations:

- Unnecessary transportation — varies dramatically based on facility layout and age

- Excess inventory — often reflects different demand patterns between regions

- Wasted motion — heavily influenced by equipment placement and facility design

- Waiting time — may indicate staffing model differences between sites

- Overproduction — sometimes reveals coordination gaps between locations

- Extra processing — often shows where corporate standards aren't being followed

- Defects — can highlight training consistency issues across sites

Mark waste spots with red dots on identical maps for each location. When you compare these visual assessments side-by-side, patterns become obvious and corporate leadership can see exactly where to focus resources first.

For teams that can't leave their workstations across multiple shifts and sites, send identical text polls asking "Where do you lose the most time each day?" in each location's preferred languages. Text responses feed into your workshops, ensuring frontline voices shape findings even when people can't attend mapping sessions in person.

Multi-Site Assessment Checklist:

- [ ] Create standardized waste mapping templates for all locations

- [ ] Schedule synchronized assessment weeks across sites

- [ ] Assign local teams using identical role requirements

- [ ] Gather same performance data points at every facility

- [ ] Compare waste patterns between locations visually

- [ ] Identify which sites should mentor others in specific areas

- [ ] Calculate dollar impact using consistent methods across all facilities

- [ ] Share consolidated findings with all locations simultaneously

Phase 3: Coordinate Training Across All Locations

Building skills across multiple sites works best when you train people using consistent methods while adapting to local needs. The challenge is ensuring quality remains high, whether someone learns at your flagship facility or your newest remote location.

Create a standardized training approach that scales across locations:

- Corporate Training Standards: Develop a core curriculum that every location must deliver identically. Focus on safety procedures, quality requirements, and improvement methods that cannot vary between sites. Keep materials visual and simple so local trainers can deliver them consistently.

- Local Training Delivery: Train local champions at each site using identical instructor guides, then let them adapt examples and practice exercises to fit their facility's specific equipment and processes. This maintains message consistency while making training relevant to each location's reality.

- Cross-Location Skills Exchange: Use your best-performing location as a training hub for specific skills. Send small teams from other sites to observe and practice proven methods, then return to implement locally. This spreads knowledge faster than trying to document everything in manuals.

- Virtual Training Coordination: For remote locations or specialized topics, deliver training via video conference with local facilitators at each site. This lets corporate subject matter experts reach every location while ensuring local support for hands-on practice.

- Skills Assessment: Create a company-wide skills matrix listing critical tasks and marking competency levels at each location. You'll quickly see where training gaps create risk and which sites have expertise worth sharing with others.

Keep training materials standardized but culturally appropriate. One-page guides, photos, and brief videos should work at any location, but examples and language may need local adaptation. Send quick check-in surveys 30 days after training, asking "What's one improvement method you've used this week?" to track which concepts stick across different locations.

Developing Cross-Site Coaching Networks

Great coaches make improvements stick across locations because they model a consistent mindset while understanding local realities. Here's how to develop them:

- Corporate Coach Training: Bring potential coaches from all locations to your most successful site for intensive skill building

- Peer Mentoring Networks: Pair coaches from similar locations so they can share challenges and solutions regularly

- Rotation Programs: Have experienced coaches spend time at different locations to understand various operating contexts

- Regular Calibration: Monthly virtual sessions where coaches discuss common challenges and align their approaches

Balance technical knowledge with local cultural fit. Someone might understand every improvement tool but struggle to engage teams at a particular location due to communication style differences.

Multi-Site Coach Development Checklist:

- [ ] Identify potential coaches from each location representing different functions

- [ ] Provide standardized coach training at the corporate level

- [ ] Create mentor relationships between experienced and new coaches across sites

- [ ] Establish regular cross-site coaching calls for knowledge sharing

- [ ] Rotate coaches between similar locations for a broader perspective

- [ ] Measure coaching effectiveness using identical metrics at all sites

Phase 4: Create Cross-Location Improvement Networks

When teams across multiple locations can spot problems, share solutions, and build on each other's ideas, continuous improvement accelerates beyond what any single site could achieve alone. The challenge is creating systems that make cross-site participation natural and rewarding.

Before asking teams to improve processes across locations, make sure they have consistent basics:

- Safety equipment that meets the same standards at every site

- Cross-training programs that transfer between locations

- Communication systems that work across time zones and languages

- Recognition programs that celebrate both local and cross-site contributions

- Authority structures that let local teams implement proven solutions from other sites

Schedule Daily Standups

Synchronized daily huddles set an improvement rhythm across all locations. Keep them to 10-minute stand-ups focused on yesterday's wins, today's risks, and one improvement goal, but schedule them so corporate can join key locations on rotation. This builds connections between sites while maintaining local focus.

Standardize Performance Analysis

Standardized visual management makes progress comparable. Use identical dashboard formats across all locations so corporate leadership can understand performance at a glance. When problems become visible everywhere using the same format, solutions spread faster between sites.

Collect Feedback From Multiple Sites

Multi-location idea-sharing systems enable fast feedback. Create sister-site partnerships where similar facilities regularly exchange improvement ideas. A setup reduction that works in Memphis gets tested in Phoenix within weeks, not months. Run monthly engagement polls asking "Have you tried an improvement idea from another location?" to track cross-site knowledge transfer.

Use Tools That Work on the Floor

Text-based communication brings cross-location learning to life. When your Texas facility discovers a maintenance technique that prevents equipment downtime, the plant manager texts a photo and a brief explanation to all site leaders instantly. Other locations can test the approach immediately and reply with their results, creating rapid learning cycles across the entire organization.

Host Mixed-Site Meetings

Mixed-site problem-solving sessions break down location silos. When operators from Atlanta work virtually with planners from Phoenix and finance people from corporate, the "not invented here" mindset disappears. Use shared metrics so all locations feel the same pull toward eliminating waste company-wide.

Consider monthly virtual workshops hosted by different locations. This helps cross-pollinate ideas and prevents each site from reinventing solutions that other facilities have already perfected.

Phase 4 Implementation Timeline:

Week 1-2:

- [ ] Synchronize daily huddle formats across all locations

- [ ] Install identical visual management systems at every site

- [ ] Launch cross-site idea-sharing partnerships

- [ ] Train all supervisors on consistent feedback protocols

Week 3-4:

- [ ] Host first multi-location problem-solving session

- [ ] Implement text-based communication for cross-site alerts

- [ ] Recognize first cross-location improvement adoptions publicly

- [ ] Address resistance with site visits and one-on-one conversations

Month 2:

- [ ] Expand synchronized activities to all shifts across locations

- [ ] Review and improve cross-site feedback processes

- [ ] Plan first company-wide improvement project

- [ ] Measure participation rates and adjust the approach by location

Phase 5: Balance Standardization with Local Adaptation

Once teams across locations are engaged and communicating well, your biggest challenge is deciding what must be identical everywhere versus where local adaptation drives better results. Without clear guidelines, corporate standards become suggestions, and local improvements never spread to other sites.

Start with one process that exists at multiple locations: changeover procedures, quality checks, or safety protocols. Use the Plan-Do-Check-Act cycle to determine what should be standardized across sites and where local flexibility improves performance.

- Plan: Set company-wide goals like "reduce changeover time by 15%" but let each location define its specific method for achieving it.

- Do: Try changes simultaneously at sister sites while monitoring the same metrics: cycle time, quality, and employee feedback.

- Check: Compare results across locations using identical dashboards that show both individual site performance and company-wide trends.

- Act: If multiple locations beat targets using different methods, document both approaches. If one method clearly works better, standardize it across all applicable sites.

Create location-flexible standard procedures that maintain safety and quality while allowing local optimization. Use photos and simple language that work at any facility, but include sections for "site-specific adaptations" where local teams document their approved variations. Update all locations immediately when core standards change and send the same message to all sites so everyone sees identical updates simultaneously.

Set up layered audits that work across locations:

- Operators confirm critical quality checks during their shift (same standards everywhere)

- Supervisors verify core methods and safety points weekly (consistent audit format across sites)

- Corporate reviews trend data and removes obstacles that affect multiple locations monthly

Use identical audit formats and scoring rubrics so performance comparisons between sites are meaningful. This not only helps benchmark success but also highlights where specific locations need additional support or training.

When audit scores at any location drop below 85%, treat it like any other defect: ask "why" five times, determine if the obstacle affects other sites, remove the barrier, and share the solution company-wide if applicable.

Multi-Site Standardization Guidelines

Must Be Identical Across All Sites:

- Safety procedures and emergency protocols

- Quality requirements and customer specifications

- Financial controls and reporting methods

- Environmental compliance procedures

Can Be Adapted by Location:

- Scheduling and shift patterns

- Staffing models and break rotations

- Material handling methods (based on facility layout)

- Communication timing (to accommodate time zones)

Standard Work Documentation for Multi-Site Operations:

- [ ] Use photos that work regardless of facility layout

- [ ] Write in language that translates well across regions

- [ ] Include safety warnings that meet all local regulations

- [ ] Test instructions at different locations with unfamiliar operators

- [ ] Update all sites within 24 hours of any core standard changes

- [ ] Store in systems accessible to all locations and shifts

- [ ] Review quarterly with input from each location for accuracy

Phase 6: Share Wins Across All Locations

Your biggest lean wins often start at one site, but the real value comes when those wins spread company-wide quickly and effectively. Multi-location organizations have a huge advantage here: when Memphis solves a problem, Phoenix doesn't have to start from scratch.

Here's how successful cross-location sharing works:

- One location tests an idea and tracks measurable results using your standard metrics

- Similar sites copy the winning method with minor adaptations for their specific needs

- Different locations modify the approach to fit their volume, product mix, or facility constraints

- Corporate tracks which adaptations work best and updates company-wide standards accordingly

Corporate leadership drives successful sharing across locations. Schedule monthly site visits on a rotating basis so executives hear directly from frontline teams about what's working. Then highlight successes in company-wide communications that reach all locations simultaneously.

A quick text from corporate leadership works better than formal presentations. "Memphis site cut setup time by 22% using new tool organization! Here's how they did it, and Phoenix is testing it next week:" builds real momentum. Text-based updates simplify cross-location communication, reaching every team member's phone instantly across all sites, even workers who don't use email regularly.

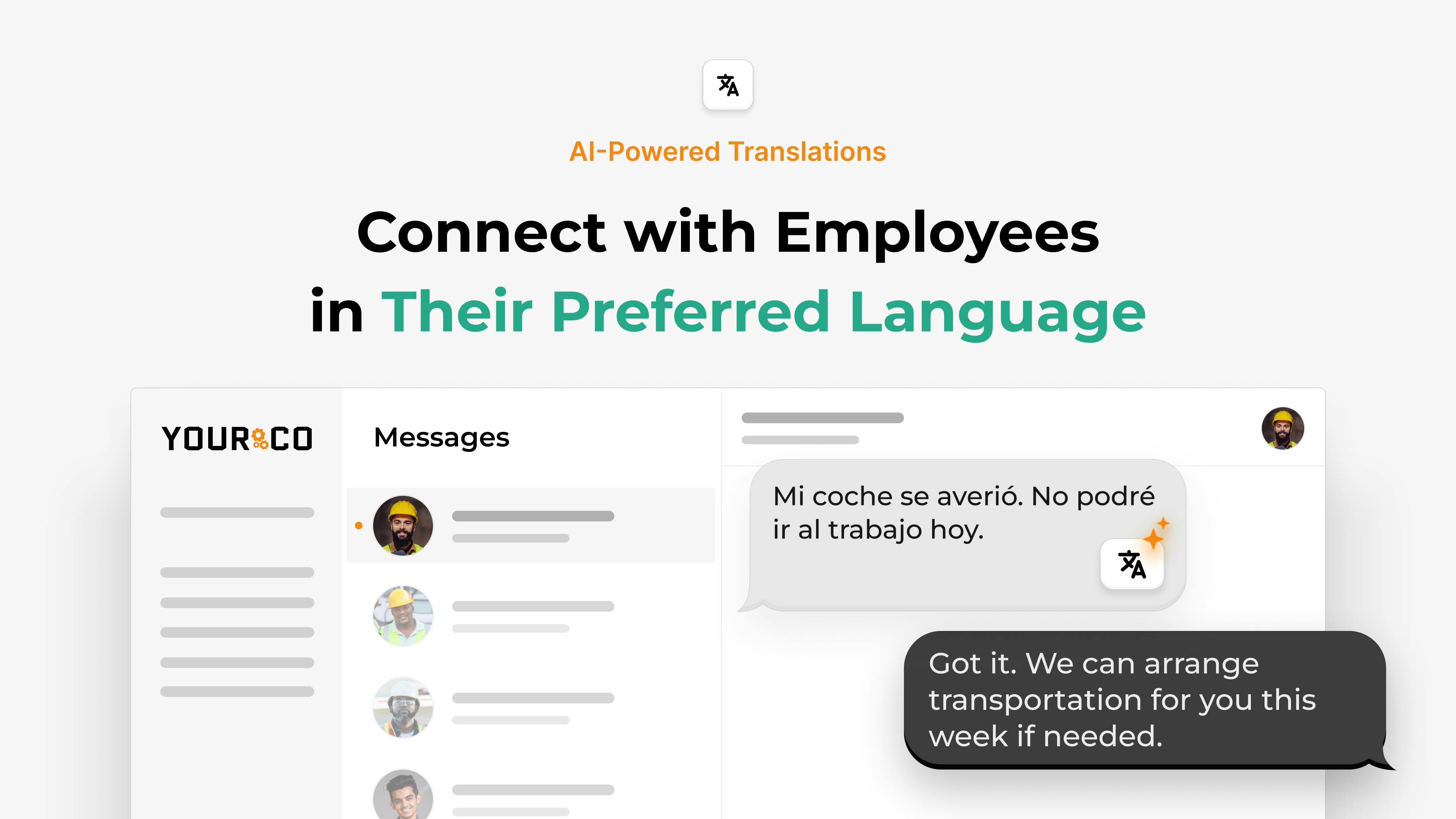

For organizations with diverse workforces, automatic translation ensures your improvement updates reach every team member in their preferred language, making participation inclusive across all locations.

Prevent Common Multi-Location Scaling Problems

- Problem: Sites copy procedures exactly without adjusting for local facility differences

Solution: Create sister-site partnerships where similar locations learn from each other and adapt together - Problem: Different locations measure the same improvements using different methods

Solution: Lock in common definitions for key metrics and use identical dashboards at every site - Problem: Improvement fatigue when wins from other sites feel irrelevant locally

Solution: Rotate which locations lead communication, recognize local adapters, and refresh challenges quarterly

Build Company-Wide Knowledge Management

Capture each improvement using a simple one-page format that works across locations:

- Problem description and impact (with site-specific context)

- Solution tried and results achieved (including local adaptations)

- Resources needed and implementation timeline

- Which other locations could benefit and any known obstacles

Store these in a shared digital system tagged by process type and location. Short videos work especially well — supervisors can record changes on their phones and share with remote teams instantly. This prevents solving the same problems multiple times across different sites.

Phase 6 Multi-Location Rollout Schedule:

Month 1:

- [ ] Identify top 3 improvements ready for cross-location sharing

- [ ] Create standardized documentation, including local adaptation notes

- [ ] Schedule corporate leadership visits to originating sites

- [ ] Plan communication strategy for company-wide rollout

Month 2-3:

- [ ] Begin rollout to sister sites with similar characteristics

- [ ] Collect feedback and successful adaptation examples

- [ ] Adjust procedures based on multi-location learnings

- [ ] Track results using consistent metrics across all implementing sites

Month 4-6:

- [ ] Expand to all applicable locations with appropriate modifications

- [ ] Document which variations work best in different contexts

- [ ] Measure company-wide impact and ROI

- [ ] Update corporate standards based on proven adaptations

Successful cross-location sharing creates positive momentum: frontline teams spot problems, solve them locally, adapt solutions for other sites, and share learnings so the entire organization gets ahead faster. Clear corporate signals, practical documentation, and fast multi-site communication turn isolated improvements into lasting competitive advantages across your entire operation.

Keep Your Multi-Site Lean Culture Moving with Better Communication

The best multi-location improvement systems depend on fast, inclusive communication that reaches every team member, every shift, every site, every day. That's where Yourco makes the difference for organizations managing multiple facilities.

Yourco's text-based platform keeps frontline teams connected in real time across all your locations, without relying on emails, passwords, or apps that don't work well on factory floors. Whether you're gathering improvement ideas from Memphis, sharing standard work updates to Phoenix, or broadcasting solutions in multiple languages across diverse sites, Yourco ensures every location gets the same message and can act on it immediately.

Every message gets tracked and archived with location-specific data, helping you prove communication consistency during corporate audits and stay aligned with compliance requirements across all sites. When someone at your Texas facility spots a safety issue that could affect other locations, they can text a photo instantly. All relevant site managers receive the alert simultaneously and can respond with confirmation, creating a feedback loop that builds trust and keeps improvements flowing company-wide.

Multi-site lean culture grows one location at a time, when feedback crosses facility boundaries quickly, problems are visible across the organization, and solutions spread faster than problems can develop. By combining proven improvement practices with reliable cross-location communication, you create an organization where continuous improvement becomes standard operating procedure everywhere.

Try Yourco for free today or schedule a demo to see how the right communication tools accelerate your multi-site lean transformation.

Frequently Asked Questions

How do we keep busy corporate leaders engaged across all locations after the initial kickoff?

Schedule monthly site visits on a rotating basis where each executive spends half a day with frontline teams at different locations, and require leaders to coach at least one cross-location improvement project per quarter. When leaders see problems and solutions firsthand across multiple sites, they stay invested in the process company-wide.

Can text messaging help coordinate improvements between locations?

Absolutely. Digital communication speeds up cross-site feedback and makes problems visible across the entire organization faster, supporting proven routines like synchronized daily meetings and standardized work reviews. The key is using technology to make multi-location coordination easier, not more complicated.

Platforms like Yourco take this a step further with Frontline Intelligence — flagging issues at specific locations, analyzing engagement data, and surfacing performance trends. These insights allow for targeted nudges, retraining efforts, or performance improvement plans, enabling managers to intervene early and apply learnings across multiple locations.

How do we handle sites at different maturity levels?

Use your most advanced location as a training hub and create mentor relationships between similar sites. Set location-specific targets that challenge each facility appropriately while rolling up to corporate goals. Focus on bringing all sites to a baseline level before pushing advanced techniques.

Should our improvement priorities be the same at every location?

Corporate safety and quality standards must be identical, but operational improvement priorities should reflect each location's biggest opportunities. Use standardized assessment methods to identify where each site should focus first, then coordinate resource allocation based on potential impact.

What if our performance data isn't consistent between locations?

Standardize measurement methods across all sites using the same definitions and collection procedures. Use the best numbers you have from each location and clearly mark what's estimated versus measured. Improving data consistency becomes part of your improvement work across all facilities.

How do we prevent internal competition between sites from hurting collaboration?

Create sister-site partnerships rather than head-to-head competition. Celebrate improvements that spread successfully between locations, not just individual site performance. Use corporate recognition to highlight collaboration between facilities rather than just local wins.

Do we need expensive software to coordinate multiple locations?

No. Consistent templates, standardized visual management, and simple communication tools work across most facilities. Many successful multi-site improvement efforts start with basic tools and add technology only when it clearly makes cross-location coordination easier.

How much training should each location receive?

Most companies blend 2-4 hours of standardized foundation training with location-specific coaching during daily work. The key is ensuring message consistency across sites while allowing local adaptation. People retain more when they can practice new skills immediately in their own facility context.

What if our locations have different languages and cultures?

Text-based communication with automatic translation works across diverse workforces, so employees can report issues and receive updates in their preferred language. This makes communication more reliable for teams that work across cultural and linguistic boundaries while maintaining consistent corporate messaging.