Supply Chain Transparency: Benefits & Implementation

Your manufacturing team discovers a key supplier shut down due to labor violations, logistics partners can't trace critical components, and customers demand proof of ethical sourcing - all while your frontline workers struggle to access vital information from the field. This common scenario plays out daily across deskless industries.

Supply chain disruptions have made transparency a business necessity. For manufacturing, logistics, construction, agriculture, and field services, the stakes are especially high. Your mobile workforce operates at the front lines of the supply chain, giving you a unique advantage in collecting real-time data and verifying conditions firsthand.

Many companies today lack full visibility into their supply chain, leaving them vulnerable to disruptions, compliance failures, and reputation damage. Here are practical strategies designed specifically for operations managers, HR leaders, and IT/security administrators in deskless environments.

You'll discover quick wins you can implement in 30 days and comprehensive long-term strategies to build transparency that strengthens operations, protects your workforce, and satisfies stakeholders. Let's transform your supply chain challenges into competitive advantages.

What Supply Chain Transparency Is - And Why Deskless Teams Can't Ignore It

Supply chain transparency means knowing and sharing what happens at every stage of your supply chain. This differs from visibility, which keeps information internal. Transparency shares verified data with external stakeholders like customers, investors, and regulators who need accountability.

Six components form transparency's foundation, each directly impacting your deskless operations. Data collection and flow mapping track materials from source to delivery. Ethical sourcing ensures fair labor practices across work sites. Environmental monitoring captures sustainability metrics affecting compliance and reputation. Traceability systems deliver real-time visibility into product origins—essential when teams operate across multiple locations. Communication protocols and stakeholder engagement ensure information flows where it's needed.

Your deskless workforce drives transparency success. Manufacturing, logistics, construction, and field service teams interact directly with suppliers, witness conditions firsthand, and capture real-time data that office systems miss. This positions them as both transparency enablers and primary beneficiaries.

Operations managers see enhanced efficiency, stronger resilience, and reduced costs through early identification of bottlenecks and risks. HR leaders gain tools for ensuring ethical labor practices, strengthening employer branding, and boosting employee engagement. IT and security administrators benefit from improved data integrity, streamlined compliance, and enhanced risk mitigation across distributed operations.

Patagonia demonstrates how open communication builds consumer trust even when disclosing imperfect practices. Authentic communication often matters more than perfect operations.

Step 1 – Map & Visualize Your Supply Chain

You can't be transparent about what you don't know. Supply chain mapping serves as the foundation for all accountability efforts, giving you the comprehensive view needed to identify risks, verify claims, and communicate accurately with stakeholders.

How to Build Your Supply Chain Map

Start with your tier-1 suppliers and work backwards through each layer. Your direct suppliers are typically the most accessible and willing to share information, making them the logical starting point. From there, trace the flow of materials and components back to their origins, mapping each connection along the way.

Collect essential data points at each node: supplier names and contact information, physical locations and facilities, materials or components provided, relevant certifications and compliance documentation, and observable labor practices. This information forms the backbone of your visibility initiative.

Use supplier self-surveys as your initial data collection method. Create standardized questionnaires that capture the information you need while remaining manageable for suppliers to complete. These surveys provide a baseline that you can then verify and enhance through field observations.

How to Choose the Right Mapping Tools

Choose visualization tools that match your organization's technical capabilities and budget. Simple spreadsheets work for basic mapping, while specialized supply chain management software offers advanced features like automated data updates and interactive visualizations. The key is selecting tools that your team can actually use and maintain.

Develop a starter data dictionary with fields for supplier classification (tier level, criticality), contact information (primary contacts, addresses, phone numbers), operational details (products/services provided, capacity, lead times), compliance status (certifications, audit results, corrective actions), and risk indicators (geographic location, financial stability, alternative suppliers available).

How to Overcome Common Mapping Challenges

Suppliers often hesitate to share information due to competitive concerns or privacy fears—address this by clearly communicating the mutual benefits of openness and starting with less sensitive information. Data inconsistencies and gaps are inevitable when working with multiple suppliers using different systems—establish clear data standards and validation processes from the beginning. If you have limited resources for comprehensive mapping, prioritize high-risk or high-impact suppliers first, then expand coverage over time.

Track your progress using a simple but effective KPI: percentage of suppliers mapped with complete information. This metric helps you measure advancement toward full supply chain visibility while identifying areas that need additional attention.

Data Collection Tactics for Deskless Workers

Your frontline workers have direct access to supplier facilities and can observe conditions firsthand, making them invaluable assets in building accurate supply network maps. Field workers can contribute by using mobile devices to capture photos and GPS coordinates of supplier facilities, reporting on working conditions they observe during site visits, and verifying supplier claims about certifications, capacity, or processes through direct observation.

Equip your field teams with specific techniques for gathering accurate information during their regular work activities:

- Train workers to use smartphone cameras to document supplier facilities, equipment, and working conditions

- Implement GPS tagging for all supplier locations to build an accurate geographic database

- Develop simple mobile forms that workers can complete during site visits

- Use SMS-based reporting systems for quick updates on supplier status or issues

- Create a structured approach to supplier conversations, providing field workers with key questions to ask

Step 2 – Engage Suppliers & Frontline Employees

Supply chain visibility succeeds or fails based on stakeholder participation. Your suppliers and frontline employees are the sources of the data and insights that make accountability possible—without their active engagement, you're building on shaky ground.

Start supplier conversations by focusing on shared benefits rather than compliance demands. Most suppliers resist these programs because they see them as burdens or competitive risks. Position your initiative as an opportunity to build trust, access premium markets, reduce operational risks, and strengthen partnerships.

Use a structured three-message outreach sequence for initial supplier contact:

- Introduce your program and explain the business benefits

- Outline specific information needs and realistic timelines

- Offer concrete support and resources to help them meet requirements

This prevents information overload while demonstrating genuine partnership.

Global supply networks require proactive solutions for cultural and language barriers. SMS-based communication tools with translation capabilities bridge language barriers in the workplace, enabling real-time updates across diverse teams. Supplier resistance often stems from communication challenges rather than unwillingness to cooperate.

Integrate data collection into existing workflows rather than creating separate tasks for frontline employees. Train field workers on how their contributions support broader business goals, and provide mobile-friendly tools that make reporting quick and intuitive. Recognition programs that celebrate contributions to supply chain visibility boost participation rates.

Build two-way communication systems that allow both suppliers and employees to provide feedback on your processes. This approach identifies practical challenges early and shows you value their input in shaping the program.

Track supplier response rates, employee participation rates, and data quality scores to measure engagement success. These metrics help identify areas needing additional support or training adjustments.

Building a Supplier Code of Conduct

Develop a supplier code that establishes clear expectations while fostering collaboration. Focus on building mutually beneficial relationships that emphasize shared values rather than punitive enforcement. Include specific requirements for information sharing, labor practices, environmental standards, and communication protocols. Provide templates and resources to help suppliers meet these standards, positioning your organization as a supportive partner rather than an auditor.

Step 3 – Implement Technology & Data Infrastructure

Choose technology that works where your people work—in the field, across multiple sites, and often with limited connectivity. The right infrastructure transforms your mobile workforce from data collectors into visibility enablers while providing real-time insight into supply chain operations.

Match technology solutions to your organization's current capabilities and resources. Start simple if you're new to supply chain visibility, then build complexity as your team's skills and needs evolve.

Basic Tools for Getting Started

Cloud-based spreadsheets and simple databases deliver immediate value for smaller operations—especially when they mirror existing safety operating procedures your frontline teams already know. Google Sheets or Microsoft Excel with cloud syncing lets field teams update supplier information, certifications, and compliance data in real-time from any device. This creates your first centralized database without significant upfront investment.

Set up basic templates that capture essential supplier details: contact information, certifications, audit dates, and compliance status. Your frontline workers can update these directly from job sites, creating a living document that stays current with actual field conditions.

Mid-Level Solutions for Growing Operations

Dedicated supply chain management software integrates with existing ERP systems and provides dashboards that give operations managers comprehensive visibility into supplier performance, compliance status, and risk indicators. Modern SCMS platforms include mobile apps designed specifically for deskless workers to report issues, verify deliveries, and update status information directly from the field.

Look for employee communication apps that sync offline data automatically when connectivity returns. Your teams shouldn't lose information because they're working in remote locations or areas with poor signal strength.

Advanced Technologies for Comprehensive Visibility

IoT sensors and devices capture real-time data on location, temperature, humidity, and other critical factors. This automated data collection reduces manual reporting burden on your field teams while providing continuous monitoring of sensitive goods and processes.

Mobile-First Solutions for Deskless Teams

Your technology choices must prioritize mobile accessibility above all else:

- SMS-based reporting systems function even in low-connectivity environments

- Cloud platforms with offline synchronization ensure data collection continues even with intermittent internet

- Progressive web apps function like mobile applications but don't require app store downloads

- Consider multilingual interfaces if your workforce speaks different languages

Data Integration and Security Considerations

Connecting new visibility tools with legacy systems requires careful planning. Focus on APIs and integration platforms that bridge different data formats and protocols. Establish clear data governance policies that define access levels and information protection standards.

Plan for gradual integration rather than wholesale system replacement. Most successful implementations connect new mobile tools to existing databases first, then expand integration as teams become comfortable with the technology.

Security & Compliance Checklist

- Implement multi-factor authentication for all platforms

- Encrypt data both in transit and at rest

- Establish role-based access controls limiting sensitive information to authorized personnel

- Conduct regular security audits of all connected systems and devices

- Maintain data backup and disaster recovery procedures

- Document all data handling procedures to meet industrial regulatory compliance requirements and avoid penalties

- Train field teams on cybersecurity best practices for mobile devices

Track your technology implementation success through system adoption rates, data quality metrics, and integration completion milestones. These indicators help identify where additional training or technical support may be needed to ensure your deskless workforce can effectively use the new tools.

Step 4 – Define Policies, Standards, and KPIs

Establishing formal policies and performance metrics transforms your visibility initiative from scattered efforts into a sustainable, measurable program. Without clear standards, even well-intentioned efforts become inconsistent, leaving gaps that undermine stakeholder trust and regulatory compliance.

Start by developing comprehensive policies. Review existing industry standards like GRI, ISO 20400, or SA8000 to understand established frameworks. Define the scope and boundaries of your requirements—will you focus on tier-1 suppliers initially or extend deeper into the supply chain? Establish clear roles and responsibilities across your operations, HR, and IT teams, ensuring everyone understands their accountability in the process. Create approval and enforcement mechanisms that specify consequences for non-compliance, and plan systematic communication and training to ensure policies reach every level of your organization.

Your policies should address several critical elements:

- Specific supplier requirements and expectations

- Data collection and verification protocols that work for your deskless workforce

- Disclosure guidelines that balance openness with competitive sensitivity

- Clear consequences for non-compliance

- Continuous improvement processes that evolve with changing regulations

Developing SMART KPIs ensures you can track meaningful progress. Focus on supplier compliance rates, data completeness and accuracy, response times for information requests, issue resolution metrics, and stakeholder satisfaction measures. These metrics should be specific, measurable, achievable, relevant, and time-bound.

For deskless environments, use mobile data collection tools and SMS micro-surveys to gather KPI data efficiently. Integration with existing operational metrics prevents tracking from becoming an additional burden on frontline workers. Automated reporting from digital platforms ensures consistent data flow without overwhelming your teams.

Establish a governance structure with clear accountability across operations, HR, and IT teams. Assign specific individuals to manage policy updates, KPI monitoring, and stakeholder communication, ensuring your program has dedicated oversight and continuous improvement.

Step 5 – Disclose & Iterate—From Internal Dashboards to Public Reports

Choose your disclosure level strategically and build continuous improvement into your accountability program from day one. Most organizations start with internal dashboards, progress to limited stakeholder sharing, then move toward public reporting as their data quality and processes mature.

Three disclosure levels determine your approach and preparation requirements:

- Internal disclosure keeps supply chain information within your organization, allowing teams to spot risks and refine processes without external pressure.

- Limited external disclosure involves sharing selected information with key customers or investors who need supply chain insights for their own compliance or sourcing decisions.

- Public disclosure makes your supply chain information available to consumers, NGOs, and the broader public through reports, websites, or third-party platforms.

When developing your disclosure approach, identify your audience first and select metrics that matter most to them. Create clear visualizations that tell your story without overwhelming readers. Establish verification procedures to ensure accuracy and plan regular updates—quarterly for internal dashboards, annually for comprehensive public reports.

Your field teams provide the reality check your program needs. Use mobile tools to collect improvement suggestions from workers who see supply chain conditions firsthand. Share success stories from the field to demonstrate progress and recognize contributions that advance visibility goals.

Open communication builds trust even when information reveals problems. When you discover issues, address them head-on by acknowledging problems, outlining corrective actions, and providing improvement timelines. This approach strengthens stakeholder confidence in your commitment to continuous improvement.

Track progress with stakeholder feedback scores, disclosure comprehensiveness metrics, and improvement implementation rates. These KPIs guide your evolution from basic internal reporting to industry-leading public accountability. Public disclosure delivers measurable benefits including consumer trust, premium pricing opportunities, and competitive differentiation—but only when supported by robust verification and clear communication strategies.

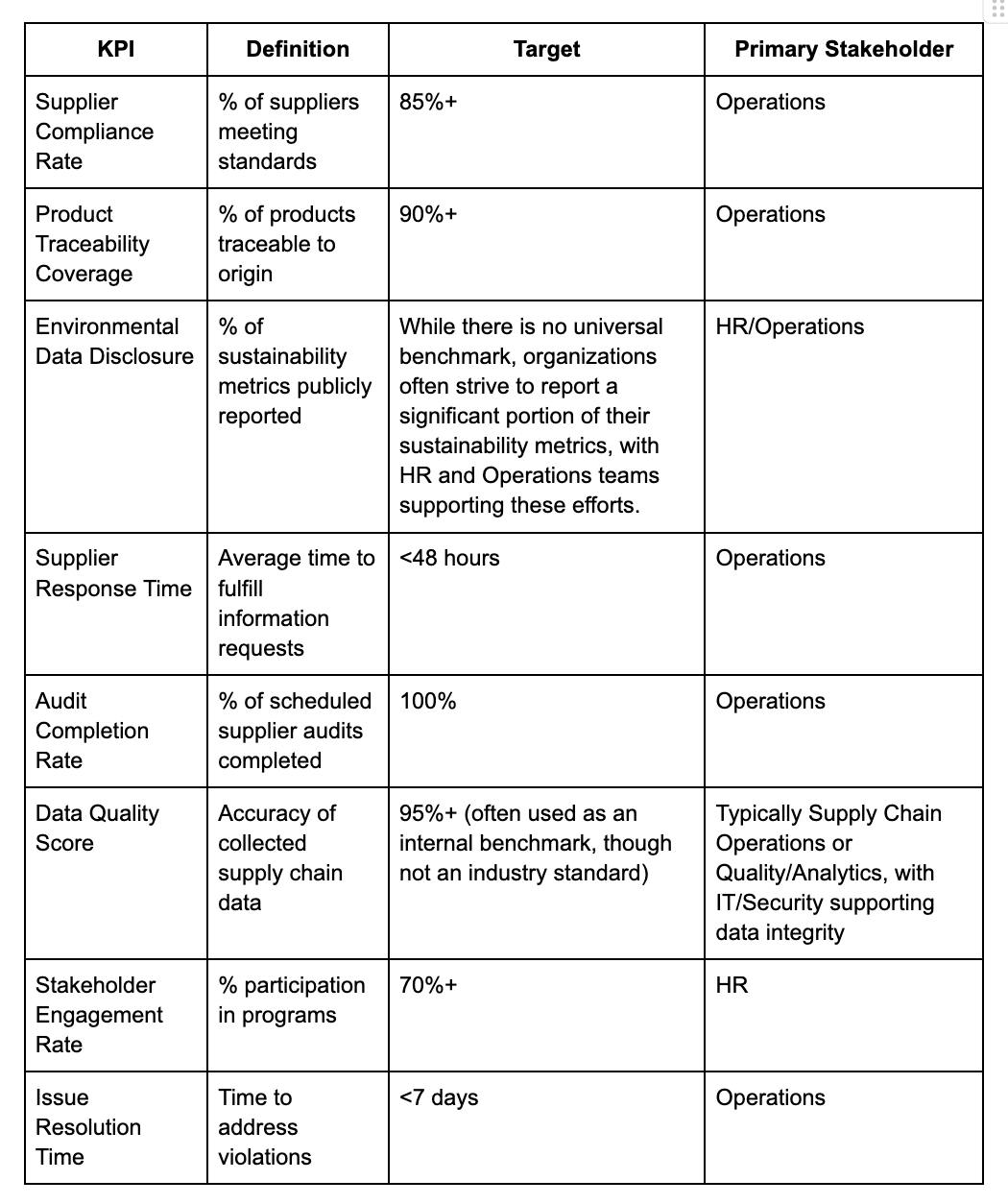

Transparency KPI Dashboard: What to Track & How to Report

Start with 8-10 essential KPIs that directly impact your supply chain visibility program. Your dashboard should provide immediate insight into performance gaps and drive specific actions across operations, HR, and IT teams.

Core KPIs to Track:

Supply chain cycle time and perfect order index often improve as visibility increases, making them valuable secondary metrics to track.

Dashboard Creation Essentials:

Choose tools that work seamlessly on mobile devices—your deskless workforce needs real-time access from the field. Power BI and Tableau offer robust features, while Google Data Studio provides simpler implementation for smaller teams. Prioritize platforms that integrate with your existing systems and support offline data entry.

Design your dashboard with color-coded indicators: green for on-target performance, yellow for attention needed, red for immediate action required. Each metric should link to specific action plans and responsible team members.

Implementation Steps:

Set up automated data feeds from your ERP, supplier management systems, and mobile collection tools. Establish weekly reviews where operations managers, HR leaders, and IT teams examine results together. Create different dashboard views for different roles—executives need high-level trends, while operational teams require detailed actionable data.

Your dashboard should evolve as your program matures. Start with fundamental compliance and traceability metrics, then expand to include predictive indicators and stakeholder satisfaction measures as your data collection capabilities grow.

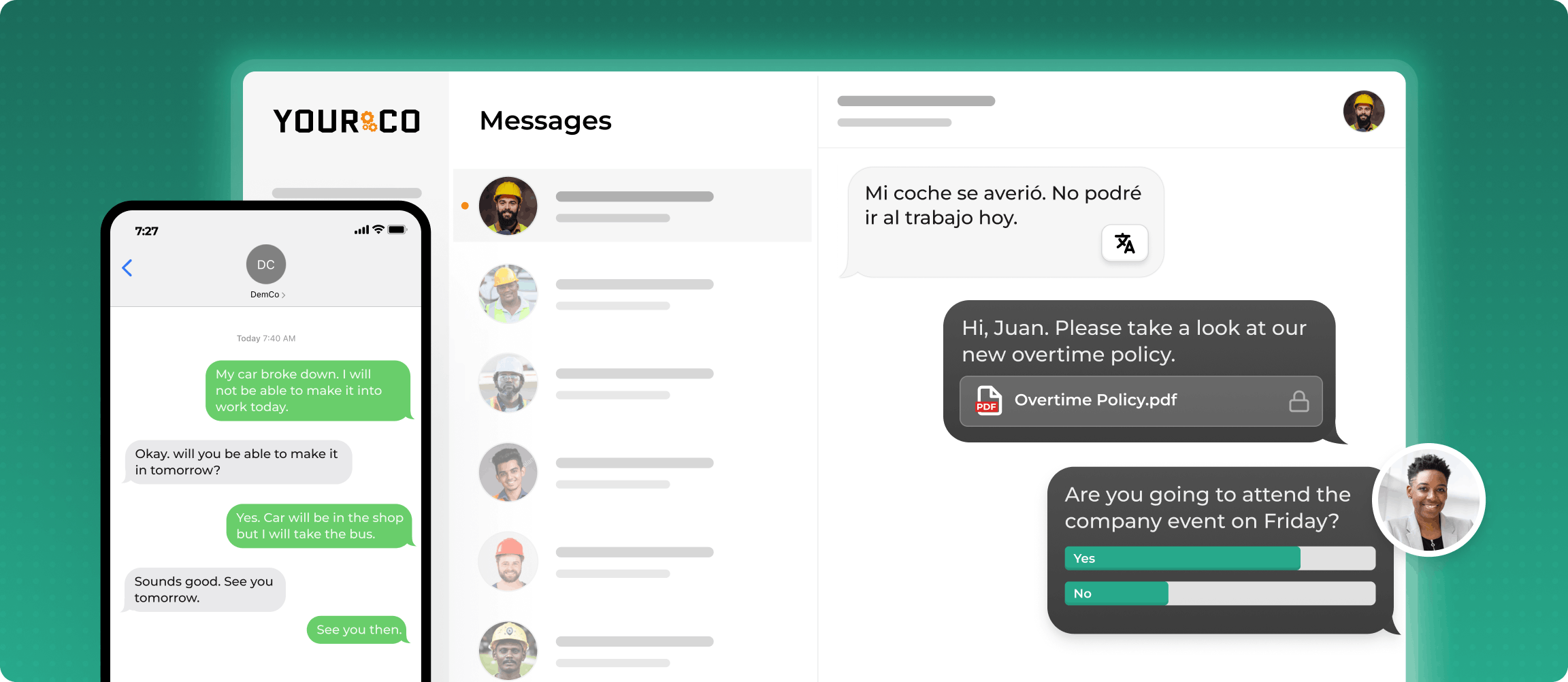

How Yourco Enhances Supply Chain Transparency

In an age where supply chain visibility is crucial, Yourco’s innovative SMS-based platform plays a pivotal role in connecting field teams, managers, and suppliers, ensuring real-time communication and data sharing across multiple levels of the organization. This makes it an ideal tool for industries that rely on deskless workers, such as manufacturing, logistics, and construction, to build the transparency necessary for modern supply chain management.

Yourco’s mobile-first approach ensures that even the most remote workers can participate in supply chain data collection, supporting key initiatives like mapping supply chains and verifying ethical sourcing practices. Through features like AI-powered translations and instant messaging, Yourco breaks down communication barriers, enabling non-desk employees to submit critical data directly from the field. Whether it's documenting the condition of goods or reporting a disruption in supply, employees can instantly communicate via SMS without requiring apps, internet access, or extensive training.

What makes Yourco particularly valuable in building supply chain transparency is its simplicity and wide-reaching accessibility. Deskless workers no longer need to rely on paper-based systems or delayed communications; they can capture real-time data, such as photos of product conditions and send them instantly to centralized systems. This helps companies like yours not only stay ahead of potential disruptions but also ensure that data is readily available for verification by stakeholders, thus improving accountability and trust.

In addition to the SMS-based communication, Yourco offers seamless integration with over 240 HRIS and payroll systems, making it an excellent tool for managing large, distributed workforces. HR leaders can use the platform for onboarding, compliance monitoring, and to ensure that workers' safety is prioritized by sending real-time alerts, collecting feedback, and managing shifts effectively across locations. Furthermore, Yourco’s enterprise-grade security features, such as end-to-end encryption and role-based access control, protect sensitive data while ensuring that the right stakeholders have the appropriate access levels.

Yourco also helps ensure compliance with industry regulations. Through its mobile platform, organizations can keep track of supplier audits, document safety practices, and streamline the reporting of incidents as they happen, ensuring that companies adhere to ethical standards and legal requirements. Whether it’s preventing violations or responding to issues swiftly, Yourco’s real-time communication tools give your teams the edge they need to drive operational success.

By incorporating Yourco into your supply chain transparency strategy, you empower your frontline workforce to gather, verify, and share key data, thus enhancing operational resilience and satisfying the growing demand for supply chain accountability. Yourco is more than just a communication tool; it is a solution that turns your deskless workforce into active participants in the transformation of your supply chain, from compliance tracking to real-time updates, ensuring your business stays ahead.

Try Yourco for free today or schedule a demo and see the difference the right workplace communication solution can make in your company.