Why Should Fire Extinguishers Be Routinely Maintained?

Wonder why fire extinguishers need routine maintenance? These devices serve as your first defense against workplace fires, but they only work when properly maintained.

Over time, extinguishers suffer pressure loss, internal corrosion, and blocked nozzles. Any of these issues renders your safety equipment useless during emergencies. Regular checks and professional servicing ensure they'll actually work during an emergency.

There's also the regulatory side. OSHA and NFPA aren't playing around when it comes to fire safety. Non-compliance penalties can exceed $16,000 per violation. Beyond avoiding fines, this demonstrates your commitment to workplace safety.

Let’s take a deeper look at why this simple maintenance task is one of the most important for your organization.

Reasons Fire Extinguishers Fail

Regular maintenance of fire extinguishers isn't optional. The difference between a minor incident and a major disaster often comes down to whether your extinguisher works when you grab it.

However, fire extinguishers face several enemies: pressure drops, internal corrosion, blocked nozzles, and chemicals that expire. Without regular checks, these problems stay hidden until the worst possible moment.

So, what does good maintenance actually do for you?

- Ensures readiness: Your extinguishers are prepared when you need them.

- Detects issues early: Catches potential problems before they escalate.

- Maintains operational capacity: Guarantees full functionality during emergencies.

- Prevents disasters: Stops small, controllable fires from growing into catastrophic events.

Professional maintenance finds the hidden issues you can't see from the outside, like internal corrosion. This matters especially in high-risk areas like manufacturing floors or construction sites where fires spread fast.

Preventive Maintenance as a Safety Protocol

Fire extinguisher maintenance forms a significant part of proactive safety strategy, checking for problems before they become emergencies. This preventive approach demonstrates a serious commitment to workplace safety rules.

This practice doesn't exist in isolation. It strengthens other safety measures, especially in high-risk environments. In manufacturing, routine extinguisher checks complement machine inspections and hazardous material storage audits. These safety systems support each other, creating a comprehensive protection against workplace incidents.

On construction sites, extinguisher maintenance works alongside scaffolding checks and PPE inspections. The difference between prevention and intervention matters tremendously with fire safety. A well-maintained extinguisher stops small fires before they grow into devastating events.

Systematic maintenance often reveals other safety insights. Patterns in extinguisher wear might indicate facility areas needing additional fire prevention measures. This information sharing makes overall risk management more effective.

Ensuring Equipment Reliability

When fires break out, extinguishers must work immediately. Regular maintenance guarantees performance when needed.

What To Check For

During monthly visual inspections, you need to verify extinguishers:

- Are in their designated spots

- Remain easily accessible

- Show no physical damage

- Have proper pressure (according to the gauge)

- Are fully charged

Critical Maintenance Checks

The annual professional maintenance goes deeper. Certified technicians examine all mechanical parts, the extinguishing agent, and expelling mechanisms to ensure everything works as designed.

- Pressure gauge: The pressure gauge indicates readiness. Technicians verify readings between 185-195 PSI during maintenance.

- Nozzle: Over time, debris or dried chemicals block nozzles, preventing proper discharge. Maintenance clears these blockages and checks for damage affecting spray patterns.

- Pin: The pin prevents accidental discharge while allowing quick access during emergencies. Technicians confirm proper insertion with intact tamper seals.

- Hose: The condition of the hose affects aim and delivery. For instance, cracks affect how well the user can aim the fire extinguisher. Each maintenance check examines the entire hose for signs of wear.

Remember that reliability isn't just what you can see. Internal examinations often reveal hidden issues like corrosion that remain invisible from the outside. These internal checks happen at specific intervals, like during the six-year maintenance required for many extinguishers.

There's also the human factor. Regular maintenance checks build confidence among everyone in your building. Your team feels safer knowing the equipment works, and this helps create a workplace where safety comes first.

The Consequences of Neglecting Fire Extinguisher Maintenance

Neglecting regular fire extinguisher maintenance leads directly to severe outcomes, including:

- Claims Denial: Insurance providers routinely deny claims if extinguishers are found improperly maintained, leaving businesses liable for the full cost of fire-related damages.

- Fines: OSHA penalties for non-compliance frequently exceed $16,000 per violation, adding significant financial burdens.

- Financial Losses: Incident response is costly. On average, the cost ratio of incident response versus prevention reaches 176:1. For example, a manufacturing facility fire causing $1.53 million in damages, downtime, and regulatory penalties could have prevented it entirely with routine maintenance costs totaling only $8,700.

- Downtime: Extended downtime after fires can be devastating, especially for small businesses. Companies that remain closed for more than five days post-disaster experience a 90% failure rate within a year. Additionally, public awareness of maintenance negligence severely damages reputation.

Taking these consequences seriously highlights the critical importance of routine fire extinguisher checks and maintenance.

Steps to Effective Maintenance

Want to keep your fire extinguishers ready for action? Here's how to make sure they'll work when you need them. NFPA 10, which covers portable fire extinguishers, mandates a clear schedule, which we have consulted to highlight the following steps:

Conduct Monthly Visual Inspections

Every month, inspect all fire extinguishers thoroughly. This efficient process verifies each unit remains functional and accessible. Staff members should check if extinguishers remain in designated locations with clear access paths. They must examine pressure gauges for proper readings within the green zone, indicating adequate pressure.

The inspection includes looking for physical damage, corrosion, leaking, or discharge signs. Verify pins and tamper seals remain intact and unbroken. Confirm instruction labels remain legible and face outward for emergency use. Document each inspection on tags attached to extinguishers, noting the inspection date and inspector's initials.

Additionally, regular checks help identify and address issues early, preventing them from compromising safety during emergencies. Specifically, inspectors should watch for these warning signs:

- Pressure gauge readings outside the normal range

- Visible damage or rust on the extinguisher body

- Cracks or blockages in the hose

- Missing pins or broken tamper seals

- Expired inspection tags

Identifying and addressing these issues early saves money and hassle. Replacing a damaged hose or resolving minor pressure problems is much less costly than handling extinguisher failures resulting from neglect.

Quick reporting further enhances maintenance effectiveness by ensuring:

- Problems get fixed faster

- Better tracking of maintenance needs across locations

- Clear accountability for regular inspections

- Solid documentation for compliance

Train multiple staff members to perform these inspections, ensuring continuity during absences. These monthly checks typically take 10-20 minutes per extinguisher and provide peace of mind that your first line of defense against fires remains ready.

Combining careful visual inspections with modern communication tools creates a proactive system that catches issues early, ensuring your fire extinguishers are ready when fires strike.

Schedule Annual Professional Maintenance

Professional maintenance occurs yearly and provides a comprehensive examination beyond visual inspections. Certified technicians disassemble extinguishers to inspect internal components for wear, corrosion, or damage. They test discharge mechanisms for proper operation and examine hoses for cracks, blockages, or deterioration.

Technicians also weigh the extinguisher to verify proper agent levels and recharge units if measurements fall below specifications. They replace worn parts, including O-rings, seals, and gaskets, which degrade over time. Experts hydrostatically test certain components to ensure they withstand pressure during discharge.

In addition, professionals recertify each unit according to current standards from NFPA and manufacturer guidelines. They update maintenance records and place new certification tags showing service dates and next maintenance requirements.

This service typically costs $15-$30 per standard extinguisher, with specialized or larger units costing approximately $100. Many facilities schedule annual maintenance during slower operational periods to minimize workflow disruption.

Finally, depending on the extinguisher type, an internal examination is required every 6 years to check internal component while hydrostatic testing is needed every 12 years to ensure the cylinder can handle high pressure.

Hire Qualified Providers

Selecting qualified maintenance providers ensures your fire extinguishers receive proper care and meet all regulatory requirements. Look for technicians certified by recognized organizations like the National Association of Fire Equipment Distributors (NAFED).

These professionals complete extensive training programs covering different extinguisher types, manufacturing standards, and testing procedures. Qualified providers also maintain specialized testing equipment calibrated to manufacturer specifications for accurate assessments.

They understand the nuances between various extinguisher types, including ABC, CO2, Class K, and clean agent systems. Professional technicians follow NFPA 10 standards precisely during all maintenance procedures. They provide detailed service reports documenting their findings and actions taken for each unit.

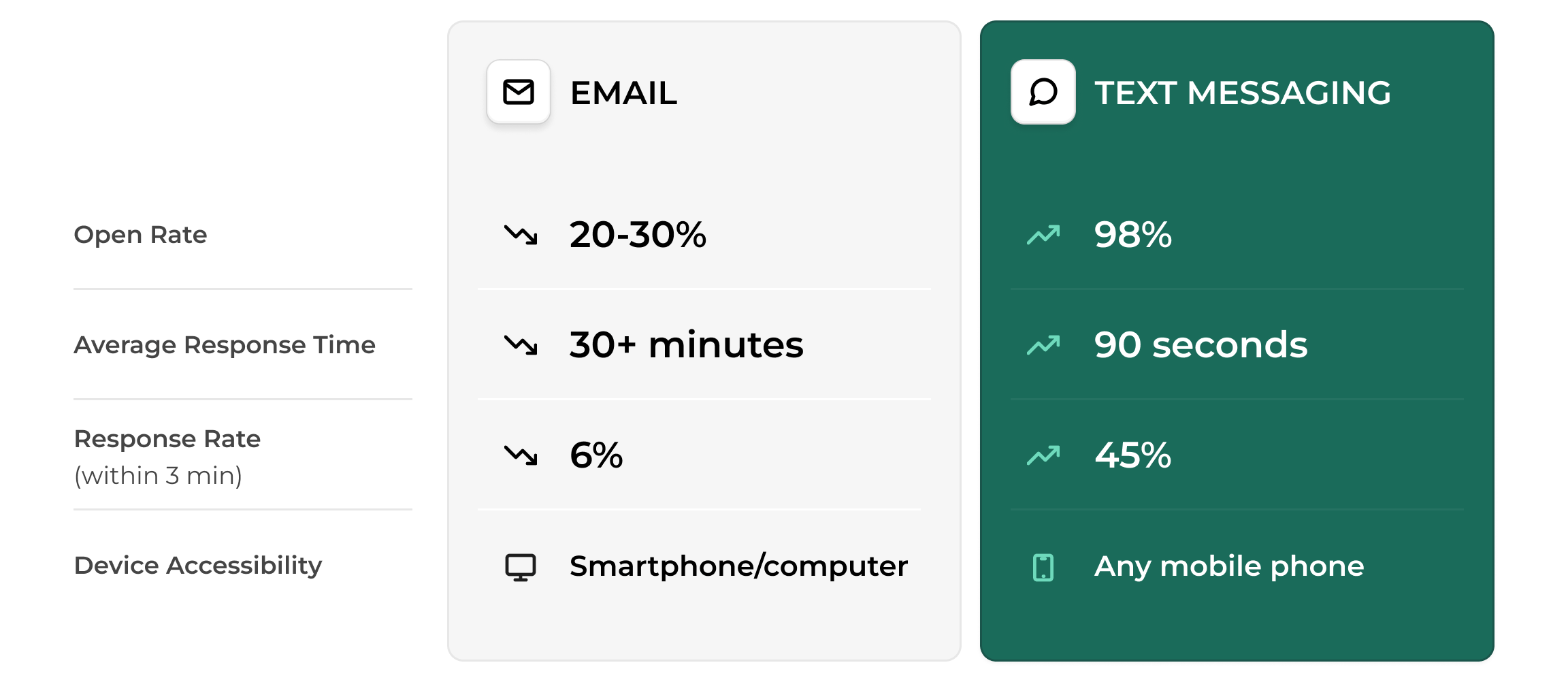

Implement Advanced Communication Tools

Modern communication systems transform maintenance management across multiple facilities. For instance, text-based platforms send automated inspection reminders to responsible personnel, ensuring timely completion of required checks. These systems allow instant issue reporting when problems arise, capturing photos of damaged equipment for assessment.

Communication tools also maintain centralized maintenance schedules visible to all stakeholders. They automatically escalate unresolved issues to supervisors after preset timeframes. SMS tools like Yourco enable field workers to receive maintenance alerts directly on personal phones without needing specialized apps.

An employee notification system also ensures staff are promptly informed during important situations. Staff can confirm completed inspections through simple text replies, reducing paperwork. Maintenance teams receive real-time notifications when inspectors discover problems requiring immediate attention. These employee alert systems generate compliance reports showing inspection completion rates and outstanding maintenance needs.

These technologies improve accountability by tracking who performed each inspection and when. Finally, communication systems integrate with work order management software, automatically generating service requests when issues arise. They store inspection history in searchable databases for quick reference during audits.

Safety First: Why Must Fire Extinguishers Be Routinely Maintained

Fire extinguisher maintenance protects lives and property. Well-maintained extinguishers successfully put out fires 80% of the time, preventing small incidents from escalating into costly disasters. Neglecting routine maintenance exposes organizations to serious risks, from claim denials and regulatory fines to significant financial losses and operational downtime.

Routine inspections and professional servicing are essential. However, efficiently managing these inspections, documenting findings, and promptly addressing issues across multiple locations can quickly become overwhelming without the right tools. Modern communication solutions like Yourco address these very challenges.

Yourco’s SMS-based platform simplifies maintenance management by delivering timely inspection reminders directly to employee phones, without the need for special apps or internet connectivity. When issues arise, employees can instantly report them through text messages, even attaching photos for immediate documentation and further investigation by their line managers. These real-time, visual reports improve accuracy, accountability, and significantly speed up issue resolution.

Additionally, supervisors gain real-time oversight of inspection statuses, detailed documentation, and compliance across every location, greatly reducing the risk of missed or delayed maintenance tasks. Yourco’s intuitive, secure, and flexible setup meets NFPA and OSHA compliance requirements and actively strengthens your organization’s safety culture.

Investing in proactive fire safety through Yourco ensures your organization's fire extinguishers are consistently and reliably maintained, safeguarding employees and operations while controlling costs.

Try Yourco for free today or schedule a demo and see the difference the right workplace communication solution can make in your company.