Manufacturing Team Intelligence: Real-Time Efficiency Implementation Guide

Manufacturing Team Intelligence helps your entire operation run on the same real-time information, so problems never sit hidden between shifts. Picture a line slowing down because a tooling update never reached the night crew, or a quality issue spreading because no one flagged it in time. These breakdowns are avoidable when daily messages, quick check-ins, and simple alerts turn into shared, visible updates that everyone can act on.

With clear communication flowing across teams and supervisors, overtime drops, production stays on schedule, and safety issues get resolved before they spread. This guide shows you how to build that real-time visibility step by step and create a floor where information moves as fast as your production.

1. Turn Daily Messages Into Actionable Production Data

Many manufacturing teams work with delayed or incomplete frontline information. Updates come after a shift ends, issues are forgotten, and leaders lose the chance to respond when it counts. Without a consistent way for employees to communicate back to leadership, companies lack real visibility into what’s happening on the production floor.

Yourco solves this by enabling daily two-way communication with frontline teams. When employees use Yourco to report issues, ask questions, submit updates, and respond to messages in real time, manufacturing leaders gain the continuous data stream needed to understand production conditions, workforce readiness, shift performance, and operational risks.

These daily messages form the foundation of Frontline Intelligence. The more employees communicate through Yourco, the more accurate and actionable the insights become.

2. Map Your Current Communication Flow

Before you improve your system, understand how information moves through your facility. Start by seeing your plant the way a message sees it. When you trace every instruction, alert, and question from sender to receiver, the weak spots jump out fast.

- Walk a product through one shift. Notice how supervisors hand off instructions to operators, how maintenance hears about breakdowns, and how quality control flags defects. Write each step on sticky notes, then line them up in the order they happen. This simple exercise reveals gaps you might miss during normal operations.

- Draw arrows between the notes to map your communication channels. Every arrow shows a pathway: face-to-face, radio, text, email, or a hurried shout across the line. Where an arrow feels slow or vague, mark it red. These red marks highlight your biggest improvement opportunities.

- Time these handoffs to spot slowdowns. Time these handoffs to spot slowdowns. You do not need formal data to start. A quick stopwatch check during a normal shift can show how long it takes for a machine fault to reach maintenance or for a spec change to reach the next cell. Identifying these delays is crucial for identifying bottlenecks in manufacturing that slow down your entire production flow. These simple observations reveal where verbal updates, unread emails, or unclear instructions slow your flow.

- Watch for confusion points as you trace the process. Repeated questions, mixed-up part numbers, or people waiting for direction all signal missing context. These patterns help you see where better communication would remove guesswork and prevent rework.

- Turn the finished map into a simple flowchart. Share it with the crew to confirm the details. Pick one red arrow to fix first. Small wins build momentum for bigger changes, and your team will see immediate improvements in their daily work.

These patterns show you exactly where instructions lose clarity, helping you prioritize which communication gaps to fix first.

3. Build Real-Time Visibility Into Production Work

Once you understand your current communication patterns, create visibility into what's happening on your floor as it happens. Catching problems early keeps your production schedule on track. Track simple signals from daily work:

- Message volume from your teams

- How quickly supervisors respond

- Safety alerts that come up

- The same questions asked repeatedly

These patterns show you trouble spots before a machine breaks down or a shift comes to a halt.

These patterns help you spot trouble early. A stretch of unanswered messages can point to an overloaded maintenance team. A drop in safety reports can show that employees are unsure about reporting. Understanding how to measure job performance through these communication signals helps you identify which teams need additional support. These signals give you time to adjust staffing, support a supervisor, or clarify a confusing process before it affects output.

Manufacturing organizations can generate this visibility by using Yourco for daily two-way communication. When operators, technicians, and supervisors send short texts throughout the day, Yourco turns those messages into Frontline Intelligence. Leaders can compare message activity across locations and see which plants resolve issues quickly and which need help.

Quick feedback keeps the information flow strong. Have operators confirm when shifts start, send a short check-in at lunch, or ask for an “all clear” after line changes. Small touchpoints create a steady stream of insight that improves decision-making.

When these daily communications are combined with data from sensors and dashboards, you get a clear picture of what is happening on your floor at the moment it happens. This gives supervisors and leaders the awareness they need to prevent delays and keep production running smoothly.

4. Connect Teams and Supervisors With Clear Updates

When supervisors give clear instructions, production stays on schedule and costly mistakes drop. Every shift handoff becomes smoother when your team follows the same routine for sharing production targets, machine updates, and quality checks. A quick text with today's goals and key safety points beats rushing through updates in the hallway, where details get missed and problems pile up.

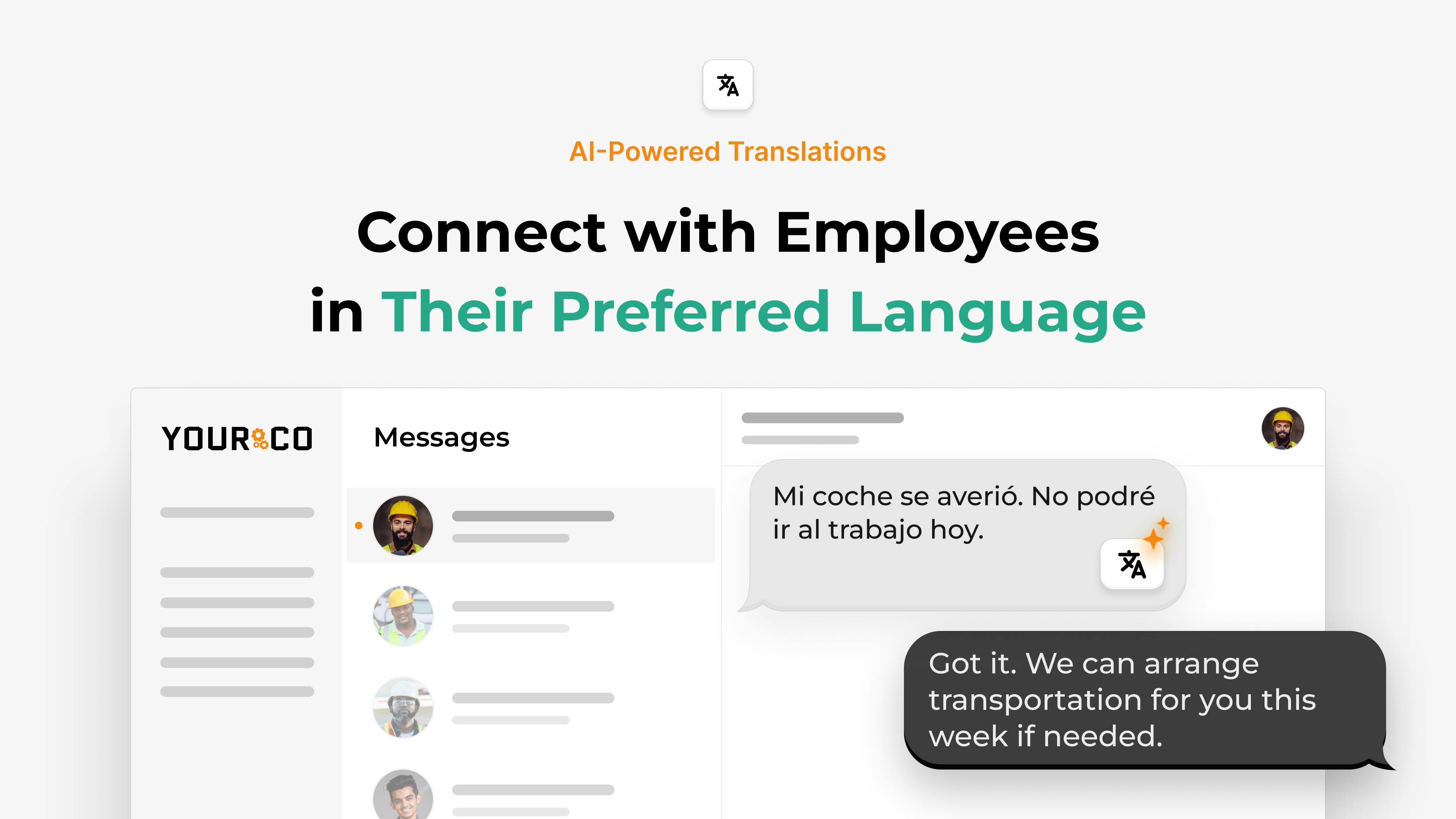

Language barriers create real headaches on the shop floor. Your crew might include workers who speak Spanish, Vietnamese, Polish, and other languages fluently but struggle with English instructions. When critical safety updates or production changes only come in English, mistakes happen, and people get hurt. Workers also feel left out when they can't fully understand what's expected of them.

Instant translation fixes this problem without extra work for supervisors. Tools that offer real-time translation let you type one message that reaches everyone in their preferred language. This helps workers follow instructions correctly and shows them that their safety matters.

With clear templates and automatic translation, your team gets the right information fast, and production keeps moving.

5. Improve Safety and Quality Reporting

Quick, easy reporting lets you spot hazards before they shut down a line or hurt someone. When every operator can send a simple text the moment something looks off, you get an instant signal to act instead of a surprise later.

Text-based incident reporting reaches everyone, even on loud, fast-moving floors. A short SMS works on any phone, so no one needs to hunt for a form or log in to a computer. Each message gets automatically time-stamped and stored. This gives you a clear record for future audits or insurance reviews. Workers who would normally keep quiet feel safer speaking up because the process takes seconds and can be anonymous.

Real-time alerts do more than document problems. They prevent downtime. Picture a forklift operator who notices an oil leak, snaps a quick photo, and texts the maintenance tag. The line pauses for five minutes, not five hours, and a batch of product stays on spec.

Your reporting system needs five components to work effectively:

- SMS access for every shift with no app required

- Auto tags for location, severity, and equipment, so nothing slips through

- Instant routing to the right supervisor or technician

- Multilingual options so teamscan read instructions in their own language

- A dashboard that tracks trends and closes the loop on fixes

When you combine these pieces, you create a feedback loop that protects people, keeps quality high, and saves costly downtime. One quick text at a time.

6. Automate Routine Updates

Automating routine communications gives you hours back while keeping every shift informed and aligned. Think about your typical Monday morning. You send shift reminders, safety updates, and training follow-ups to the same groups. Instead of typing these messages repeatedly, automation handles them while you tackle bigger problems.

Start with your most common updates. Shift reminders work perfectly for automation, along with maintenance alerts, safety checks, and training confirmations. Yourco lets you write a message once, choose the crew you want to reach, and quickly add details like dates or line numbers. The update goes straight to any phone as a text message, so everyone stays informed without downloading anything or learning a new system.

Build your automation gradually. Begin with daily needs like shift start times and break schedules. Then add weekly training reminders and monthly compliance updates. Keep each message short and clear, sending it in each worker's preferred language when possible.

Check your results weekly. If people keep asking the same questions, adjust your initial text rather than sending more messages. Smart automation cuts your manual work, prevents missed updates, and lets you spend time where it matters most.

7. Follow a Simple Implementation Workflow

Start small, prove value quickly, then scale the process across lines and locations. Follow this seven-step roadmap to keep momentum and avoid common pitfalls.

- Review current flow (Week 1): Walk the floor and sketch how instructions and updates travel between operators, maintenance, and quality. Note delays or missed hand-offs that slow production.

- Spot the gaps (Week 2): Time how long messages take to reach the right person. Communication delays create ripple effects that lead to overtime and rework, so minimizing these delays helps your bottom line.

- Standardize updates (Week 3): Pick one channel for shift notes, job changes, and quality checks. SMS works best because every worker can read these messages without downloading apps.

- Launch simple reporting (Week 4): Give operators a single number to text hazards or machine issues. Time-stamped logs replace paper forms and create instant documentation.

- Automate routine messages (Month 2): Schedule shift reminders, maintenance alerts, and safety tips. This frees supervisors to focus on coaching instead of repeating the same information.

- Track weekly trends (Ongoing): Compare response times, incident counts, and efficiency metrics. Real-time monitoring can boost plant efficiency by up to 20%.

- Refine and expand (Quarterly). Trim duplicate alerts, add new metrics, and roll successful pilots to the next line. Smart filtering prevents information overload.

If you hit resistance, start with one shift and share quick wins to build support for the next rollout.

Transform Your Floor With AI-Powered Frontline Intelligence

Your frontline workforce generates valuable data every day through texts, reports, and daily interactions. The challenge is that most of that information never reaches you in a format you can actually use. By the time traditional reports arrive, problems have already snowballed.

Yourco turns every message into actionable intelligence. The platform captures communication patterns, response rates, safety alerts, and engagement signals across all your locations. Every text is time-stamped and logged, creating a searchable record for compliance reviews.

Yourco's AI-Powered Intelligence transforms this communication data into real-time insights. Instead of waiting for quarterly surveys or filtered manager reports, you spot issues as they emerge. Ask questions like "What's employee sentiment been like for the past two weeks?" or "Have there been any safety concerns reported across sites in the Eastern United States?" The AI analyzes message activity and response patterns to give you answers based on actual frontline data.

This intelligence shows you when teams start to disengage, alerts you to safety risks as they happen, and helps you plan staffing by pointing out where you may be short on people.

The platform automatically translates messages into over 135 languages and dialects, so multilingual teams understand instructions clearly, and you capture insights from your entire workforce. No apps to download, no training required.

Try Yourco for free today or schedule a demo and see the difference the right workplace communication solution can make in your company.

Frequently Asked Questions

How does real-time team intelligence differ from traditional manufacturing reports?

Traditional reports show you what happened hours or days ago, after problems have already impacted production. Real-time team intelligence gives you live data as work happens, so you can spot issues like rising scrap rates or equipment slowdowns before they cause shutdowns. This shift from reactive to proactive management helps supervisors coach teams, schedule maintenance, and adjust staffing before small problems grow into costly delays.

What communication signals should I track to improve production efficiency?

Start with simple metrics that reveal trouble spots: message volume from each shift, supervisor response times, safety alert frequency, and repeated questions from operators. Too many unanswered messages might mean your maintenance crew is overwhelmed. Fewer safety reports could signal that workers don't trust the reporting process. When you combine these communication insights with production data, you see exactly where to provide support before efficiency drops.

How can I get workers to actually use a new reporting system?

Make reporting as simple as sending a text. Workers who would normally skip paperwork will report issues when they can snap a photo and send it from their phone in seconds. No apps, no logins, no hunting for forms. Every message gets time-stamped automatically, creating documentation without extra work. When workers see supervisors respond quickly to their texts, trust builds and reporting increases naturally.

Can team intelligence help reduce turnover in manufacturing?

Yes. Communication patterns often reveal disengagement before workers quit. When operators stop confirming shifts, go quiet, or suddenly ask basic questions repeatedly, these signals point to confusion or frustration. Dashboards that track message activity across shifts help you spot which teams need extra training or support. By addressing these issues proactively, you can improve satisfaction and retention.

How do I prevent information overload when implementing real-time communication?

Start with automation for routine updates like shift reminders and safety checks, which reduces repetitive manual messaging. Use templates for common situations so supervisors can send clear, consistent information quickly. Filter alerts by role and location so workers only receive relevant messages. Check results weekly and trim any duplicate or unnecessary alerts. Smart filtering keeps communication focused on what matters most to each team member.