Overcoming Bottlenecks in Manufacturing: A Strategic Guide for HR and Operations Managers

Bottlenecks are more than just nuisances in manufacturing. They silently drain productivity and reduce profit margins, ultimately straining your team's morale. Imagine your production line operating smoothly and efficiently until suddenly a single step stalls. This delay cascades through your entire system, leading to frustration, idle resources, and escalating costs. Whether the underlying issue involves aging machinery, skill shortages among your workforce, or poor factory layouts that force unnecessary movement, bottlenecks prevent your operation from reaching its full potential.

However, identifying and resolving these bottlenecks is entirely achievable. This guide offers a clear, actionable framework to help you pinpoint the root causes of manufacturing slowdowns, develop targeted response plans, and systematically eliminate bottlenecks to restore productivity and profitability.

Top Bottlenecks in Manufacturing You Need to Fix Now

Here are the most common reasons your factory floor slows down and how to spot them:

Equipment Problems — Old or poorly maintained machines break down and run slowly, forcing entire lines to wait. Technical issues directly limit production capacity and create costly downtime that ripples through the process.

Staff and Skills Gaps — High turnover and scheduling problems leave critical positions empty. Even perfect equipment sits idle without trained operators who understand how to maximize efficiency.

Poor Factory Layout — Extra movement between workstations wastes time and creates errors. Products travel unnecessary distances, slowing everything down.

Supply Chain Issues — The semiconductor shortage that paralyzed auto manufacturing shows how upstream problems can halt entire production lines.

Quality Problems — High defect rates force rework that clogs production lines and creates a domino effect of delays.

Forecasting Mistakes — Both overproduction and underproduction create ripple effects throughout your system.

Team Communication — Poor information flow between teams turns small issues into major bottlenecks.

Most facilities face multiple bottlenecks simultaneously. Success comes from tackling several root causes together rather than fixing them one by one.

How to Identify Every Type of Bottleneck in Manufacturing?

Understanding different bottleneck types helps you diagnose and fix them faster.

Temporal Bottlenecks

Short-term bottlenecks disrupt production temporarily but resolve quickly. These include equipment breakdowns, staff absences, brief material shortages, and power outages.

Long-term bottlenecks reveal systemic issues that persistently limit output. These include understaffed workstations, outdated machinery, inefficient workflows, and poor factory layouts.

Behavioral Bottlenecks

Static bottlenecks show consistent patterns, appearing at the same points in your production process daily.

Dynamic bottlenecks move around based on variables like product mix, batch size, or seasonal demands.

Warning Signs and Detection Methods

Watch for inventory piling up before specific processes, idle workers after bottleneck points, long queue times, operators rushing at certain stations, and recurring maintenance issues.

Six proven methods to spot constraints:

- Visual Inspection - Watch for material pile-ups throughout the production floor.

- Cycle Time Analysis - Map and compare workstation cycle times. The longest cycle time is your bottleneck.

- Value Stream Mapping - VSM reveals where value stalls across your entire process flow.

- Root Cause Analysis - For complex bottlenecks, structured problem-solving digs past surface symptoms.

- Real-Time Monitoring - Modern maintenance systems use IIoT sensors to track machine performance.

- AI-Powered Prediction - Manufacturing Execution Systems with AI detect constraint patterns before they impact production.

Start with basic visual checks and cycle time measurement, then add VSM and digital monitoring for persistent bottlenecks.

Comprehensive Approach to Fixing Bottlenecks in Manufacturing

If a bottleneck shows up mid-shift, don’t panic. Here’s a fast response plan to get things moving again within 30 minutes:

Quick Response: 30-Minute Emergency Fix

When production suddenly slows down, use this 5-step emergency response to quickly address immediate problems that threaten daily production targets:

- Scan for Visual Indicators - Look for inventory piling up before specific stations or idle workstations downstream. Physical evidence provides immediate clues about the bottleneck location and severity. Pay special attention to unusual patterns that differ from normal operation.

- Time the Process Steps - Measure how long each station takes, focusing on areas with inventory buildup. Static bottlenecks appear in the same spot daily. Documenting actual cycle times helps quantify the impact and prioritize response actions based on data rather than assumptions.

- Control Upstream Flow - Slow down the processes feeding into your bottleneck. This prevents drowning the constraint with too much work, which creates further congestion. Temporarily adjusting upstream production pace helps stabilize the system while more permanent solutions are developed.

- Deploy Resources to the Bottleneck - Add extra hands at the struggling station, bring in backup equipment, schedule targeted overtime, or move less critical tasks elsewhere. Focusing resources at the constraint point delivers maximum impact on overall throughput. Consider cross-training staff to provide flexible capacity.

- Monitor and Adjust - Restart production with your new setup and check results every 10 minutes. Keep tweaking until the flow improves. Tight feedback loops ensure that your interventions are having the desired effect and allow for rapid course correction if needed.

This quick response helps you stabilize, but don't stop here. Real fixes need a deeper approach that addresses root causes rather than just symptoms. Emergency measures should transition to sustainable solutions.

7-Step Action Plan for Permanent Solutions

For lasting solutions to manufacturing bottlenecks, follow this systematic framework that addresses both technical and organizational aspects of constraint management:

1. Find the Problem

Spot production slowdowns by checking for inventory buildup, idle time downstream, long cycle times, and quality issues at specific points. Use data collection tools to verify observations and quantify the exact impact of each bottleneck. Consider developing a bottleneck severity index to prioritize your response effectively.

2. Measure the Damage

Track key metrics like lost throughput, extended lead times, cost increases per unit, and missed deliveries. Quantifying the business impact helps secure resources for improvement projects and establishes baseline measurements for evaluating solution effectiveness. Include both direct costs and opportunity costs in your calculations.

3. Put Out the Fire

Implement quick tactical fixes like adding temporary staff, creating buffer zones, routing simple products through alternatives, and adjusting schedules for critical orders. These containment measures protect customer commitments while more comprehensive solutions are developed. Clear communication about temporary measures helps maintain team alignment.

4. Dig Deeper

Use proven diagnostic tools like the 5 Whys technique, cause-and-effect diagrams, process capability studies, and value stream mapping. Deep analysis prevents solving symptoms instead of the underlying issues. Involve cross-functional teams to gain diverse perspectives on constraint causes and potential solutions from different operational viewpoints.

5. Improve the Process

Make targeted improvements to eliminate waste and enhance flow through your constraint points. Standardize workflows at problem points to reduce variability and improve consistency. Improve material flow through layout changes that minimize transport and waiting time.

Balance station workloads to eliminate peaks and valleys in capacity requirements. Cut changeover times with SMED techniques to increase available production time. Process changes alone can reduce bottlenecks by 30% without major investment.

6. Automate Smartly

Use technology where it makes the biggest difference. Focus your automation on the steps that slow you down the most.

Set up real-time monitoring tools so you know when a problem is starting, not after it’s too late. Test new ideas with digital models before changing anything on the floor. And use AI to spot patterns and predict future slowdowns before they happen.

The goal isn’t just to automate—it’s to solve real bottlenecks. Prioritize what will actually speed up production and give you the best return on your investment.

7. Build Systems that Last

Once you fix a bottleneck, make it easy to spot the next one. Put up visual tools like dashboards or color-coded alerts that show where things are slowing down. Make sure every shift gets clear updates so everyone stays on the same page.

Track simple metrics—like wait times or work-in-progress piles—to catch new issues early. And create standard procedures for dealing with bottlenecks so your team knows what to do every time.

Fixing one problem often uncovers another. That’s normal. Great manufacturing teams keep looking, fixing, and improving—again and again.

How to Avoid Common Mistakes When Solving Bottlenecks in Manufacturing

Even the best plans can fail if you make these common mistakes while trying to fix bottlenecks:

- Fixing the symptom, not the cause

Seeing a pile of unfinished work (WIP) doesn’t mean you’ve found the real problem. That’s just a symptom. You need to look deeper to find what’s really causing the delay. Also, don’t ignore people—managing workplace stress is just as important as fixing equipment or processes.

- Relying on old data

Things change fast on the production floor. If you're only using old reports, you're preventing wasted efforts on outdated problems. Use real-time data to see what's happening now, not last week.

- Automating broken processes

Don’t add tech to a bad process—it’ll only make the problems happen faster. Always fix and improve the process first, then think about automation.

- Skipping operator training

New tools and machines are useless if your team doesn’t know how to use them. Without training, the people become the bottleneck. Make sure your staff knows how to operate and maintain every upgrade.

- Forgetting that bottlenecks shift

Solving one slowdown often creates another somewhere else. That’s normal. Keep watching and adjusting—bottlenecks move, and so should your focus.

Keep Production Moving with Smarter Communication

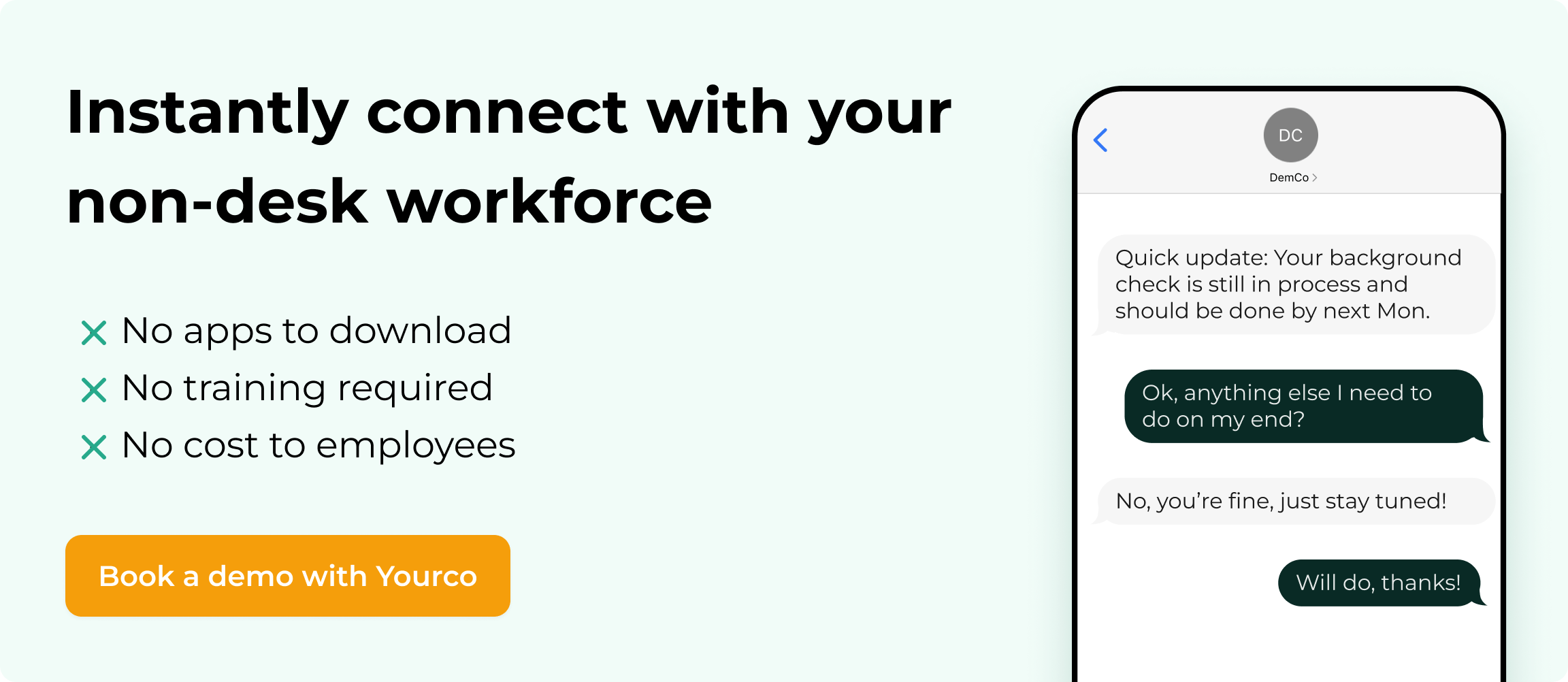

When a bottleneck strikes your manufacturing operation, every second counts. Email inboxes get overlooked, app notifications often go unchecked, and face-to-face meetings aren’t always practical. Text messaging, however, cuts through all that noise. With a nearly 98% open rate, SMS ensures your frontline teams receive and act upon critical information instantly. This speed and reliability make texting uniquely suited to rapidly resolving production bottlenecks.

Yourco harnesses the power of SMS, creating a streamlined, two-way communication channel between managers and frontline workers. Unlike apps that require downloads or emails buried in busy inboxes, Yourco’s SMS-based platform delivers instant alerts directly to workers’ mobile devices, ensuring rapid response. Workers can immediately reply, enabling them to report emerging problems or bottlenecks in real time. They can also capture and send pictures or short videos via SMS, providing visual evidence of equipment issues, quality defects, or material shortages, making diagnosis and resolution faster and easier.

Additionally, Yourco provides automated alerts and customizable notifications for shift scheduling, supply-chain disruptions, equipment maintenance reminders, and process updates. This proactive approach helps your team anticipate and prevent bottlenecks before they escalate, significantly reducing downtime and improving overall productivity.

Don’t let outdated or slow communication hold back your manufacturing performance. Equip your teams with the instant, responsive communication tools they need to spot and fix problems faster.

Try Yourco for free today or schedule a demo and see the difference the right workplace communication solution can make in your company.